Packaged Drinking Water Machine

650,000 Per Piece

1 Piece (MOQ)

Soda Bottle Filling Machine

185,000 Per Piece

1 Piece (MOQ)

Best Deals from Bottling Plant

50 L Water Demineral Plant

Get Price Quote

1 Set (MOQ)

Pocket Perfume Bottle Filling Machine

650,000 Per Piece

1 Piece (MOQ)

Empty Bottle Packing Machine

400,000 - 1,000,000 Per Unit

1 Unit (MOQ)

Bottle Filling Machine

Get Price Quote

Semi Automatic RO Bottling Plant

1,800,000 Per Set

1 set (MOQ)

Product Details: Hassle-free performance Accurate dimensions Rugged Built Long lasting service life Easy installation Easy usage

Automatic Liquid Bottle Filling Machine

Get Price Quote

1 Piece (MOQ)

Automatic Liquid Filling Machine

300,000 Per Piece

1 Piece (MOQ)

The transactions related to payment carried out between us and our clients are kept confidential. You details are not shared with anyone except the concerned personnel to ensure high level of security. Headquartered in Maharashtra(India), we are acknowledged for providing excellent products domestically.

Mineral Water Automatic bottling plant

Get Price Quote

We are leading and reputed manufacturer of Mineral water related machineries for water treatment and packaging. We install entire Mineral water /packaged drinking water plant (Fully Automatic as well as Semi Automatic) on Turnkey basis. We provide end to end services right from plant design to getting ISI license. We also provide marketing help to customers to sell their products in the market. We supply and install entire project as per Indian Standard specifications IS 14543:2004. Our products and service quality are highly appreciated & accepted by the industry and customers. As a result, we always remain at the forefront of the industry and we have 500 plus satisfied customers all over India. We have our state of the art manufacturing facility in Surat, Gujarat. We design and manufacture following products for water treatment and packaging. WATER TREATMENT/ PURIFICATION PLANTS: Reverse Osmosis plant, Water softening plant, Demineralization plant, Industrial RO plant, Drinking water treatment plant, Mineral water plant of capacity 250LPH to 30000 LPH and even higher capacity BOTTLE RINSING, FILLING AND CAPPING MACHINE (AUTOMATIC): We manufacture manual as well Fully Automatic Bottle rinsing, filling and capping machine of capacity 24BPM to 120BPM and even higher capacity. We also supply online fully automatic labeling machine and Batch coding device to make Bottling unit fully automatic. 20 LITER JAR WASHING, FILLING AND CAPPING MACHINE: We manufacture manual as well Fully Automatic 20 Liter Jar washing, filling and capping machine of capacity 100JPH to 450JPH and even higher capacity POUCH PACKAGING MACHINE: We manufacture Automatic pouch packing machine for filling liquid (water, milk, buttermilk) volume of 100ml to 500ml CUP / GLASS RINSING, FILLING AND SEALING MACHINE: We manufacture Automatic Cup / Glass rinsing, filling and sealing machine of capacity range from 30 CPM to 90 CPM BLOW MOULDING MACHINE (FOR MAKING PET BOTTLES):

Automatic Superglue Bottle Filling Machine

Get Price Quote

Feature : Suitable for cyano filling in bottles. 8 Station Rotary type model Compact in design Screw Capper Drip free filling 1HP Main Motor Drive Stainless Steel Construction Reputed make electrical Control Panel Geneva Mechanical Indexing Unit

Water Chilling Plant

50,000 - 110,000 Per Piece

air cooled and water cooled chilling plant, brine chilling plant, ahu, repair & revamping of any make chiller

Bottle Jar Packing Machine

Get Price Quote

rotary bottle washer

Get Price Quote

Semi automatic bottle brushing and washingrinsing machine is suitable for all kinds of bottles, vials, jars etc. It consists of following units. Brushing unit: Available in 2 or 4 heads. Have SS covered body and robust construction. Rotating Chucks are provided to hold the brushes of suitable size for brushing the bottles. Rinsing unit: each unit is made out of SS304, consists of 12 SS rinsers . valve is provided for controlling flow of water. Leak proof construction. Whole unit is constructed over a drainage tray to avoid spillage of water out of tank. Rubber corks are provided over rinsing tray to avoid chipping of bottles. SS tank with sink: Brushing and rinsing units are fitted on the SS tank. Waste water is stored or can be drained out by using sink. The whole structure is made out of 16 gauge SS. Motor Drive: 1HP, single phase. Output: up to 30 bottles with 2head, 1 rinsing unit.

PET Bottle Filling Machine

Get Price Quote

Our company’s name figures in the list of renowned Manufacturers and Suppliers of Pet Bottle Filling Machines from Maharashtra. The Pet Bottle Filling Machines we make available come in world class design standards that meet the diverse requirements of different buyers. Pet Bottle Filling Machines offered by us find application in different industry sectors and are used for filling of products like natural juice, milk, mineral water, synthetic juice, carbonated drink and others. Features : Bottles are fed into air conveyor and the bottles are guided into first turn table which sets up alignment to be transferred to rinsing section In rinsing section bottle is turned through 180 deg bottle inverting guide equipped with flexible joint At rinsing table water jets out only through three nozzles and the rest of movement for drip cycle where the left out water particles drips out from the bottle Rich industry experience in offering filling machinery interface for PET bottles Machines made available in Fully & Semi-Automatic working possibilities Can handle filling of PET bottles in different functional capacities Specifications : Filling Machines made available for PET Bottles with bottle handling capacity from 200 ml to 2000 ml. Some of the outputs these machines can deliver include: PET bottle filling capacity of 25 Bottle/min (BPM) PET bottle filling capacity of 50 BPM / 75 BPM PET bottle filling capacity of 120 BPM / 150 BPM PET bottle filling capacity of 200 / 300 / 400 BPM The filling capacity of the machines for PET bottles can also be customized as desired by the customers Application : Filling of PET bottles in different capacities

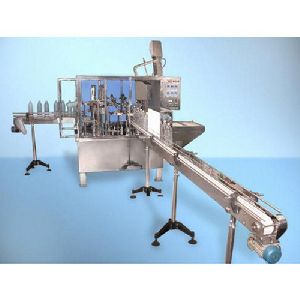

Rinsing Filling Capping Machine

Get Price Quote

Rinsing Filling and Capping Machine For Mineral WaterTechnical Specification : Bottles are conveyed through air from the feeding end. The feeding end conveying is neck holding type. The bottles are picked up from the conveyor end and are inverted for washing, after washing bottles are transferred to the filling rotor where the filling is done. Filling is time based. After filling the bottles pick up the cap and go towards the capping head where the head descends on the cap of the bottle and tighten it. Caps in the bowl are oriented and brought out through the chute. The container is then released on to the out feed conveyor of the machine. Then it conveyed to shrink tunnel mounted on conveyor. Machine is provided with vibratory hopper for cap orientation and feeding. No container V No Fill and No cap system. Contact parts in Stainless steel 316 quality. Provided with attachment of one size of pre form and one size of caps. Provided with motor gearbox and variable frequency drive. Provided with UV tubes in filling and capping area. Provided with inspection area of 2 feet. Provided with shrink tunnel. 415 Volts, 50 Hz AC 3 phase power supply. Rinsing Counter Pressure Filling and Capping Machine For Areated WaterTechnical Specification : Bottles are conveyed through air from the feeding end. The feeding end conveying is neck holding type. The bottles are picked up from the conveyor end and are inverted for washing, after washing bottles are transferred to the filling rotor where the filling is done. Filling is time based. After filling the bottles pick up the cap and go towards the capping head where the head descends on the cap of the bottle and tighten it. Caps in the bowl are oriented and brought out through the chute. The container is then released on to the out feed conveyor of the machine. Machine is provided with vibratory hopper for cap orientation and feeding. Counter pressure filling system. No container V No Fill and No cap system. Contact parts in Stainless steel 316 quality. Provided with attachment of one size of pre form and one size of caps. Provided with motor gearbox and variable frequency drive. Provided with UV tubes in filling and capping area. Provided with inspection area of 2 feet. 415 Volts, 50 Hz AC 3 phase power supply.

bottle packaging machines

950,000 Per Piece

PET Bottle Filling Machine

Get Price Quote

These machines also support the demands of applications involving plastic forming, UV bacteria killing, fixed quantity filling, date printing as well as automatic sealing and cutting. Further, the sealing temperature delivered is based on an automatic control that ensures a steady and beautiful packaging provided to the product. Features In feed Air Conveyor available in stainless steel body finish with 2.5 mtr length along with drive Outfeed Conveyor available in stainless steel body finish with 7.5 mtr length along with drive Support provided by Electrical panels, timers, relays, PLC, and other component parts so as to assure of optimum functional support Presence of inspection board mounted on outfeed conveyor Presence of shrink tunnel for handling the demands of shrinking labels and cap sleeves System available with option of one set of change parts for one size of bottles For handling different size bottles, different change parts are needed (provided at additional costs) Support provided in form of computerized digital batch & date coding machine to match with machine operations (Optional)

Bottle Cleaning Machine

Get Price Quote

Manual Perfume Bottle Filling Machine

550,000 Per Piece

1 Piece (MOQ)

rotary bottle washer

Get Price Quote

Our range of rotatory bottle washers consist of a rotary station with jet cleaning for better and faster cleaning of Glass and PET Bottles. The rotatory station facilitates cleaning from both inside as well as outside. High pressure from the nozzle is used to effectively remove dust particle from the surface. We have rotary bottle washing machine available in 326496 station and solenoid valves are provided to unable the regulation of wash timings and sequence of various washing to suit specific requirements.

Mineral Water and Juice Filling Line

Get Price Quote

This line consists of infeed air conveyor, automatic multi head rinsing, filling, capping machine& bopp labeling machine or shrink tunnel.

Bottle Filling Machine

Get Price Quote

Bottle Filling Machine

Get Price Quote

1 Piece (MOQ)

Automatic Liquid Filling Machine

Get Price Quote

We offer Automatic Liquid Filling Machine with no bottle and no fill attachment. The speed of our high quality Automatic Liquid Filling Machine depends upon number of syringes. The Automatic Liquid Filling Machine is available in double, four, six and eight head model for higher output. Our Automatic Liquid Filling Machine has diving arrangement for foaming product as well as specially designed nozzles for drip proof filling. Used In Cosmetic industryPharmaceuticals industryFood industryChemical industryAgro industry Technical Specifications 5ml to 1000ml of filling rangeSS 304 / 316 contact parts1 H.P up to 2 H.P motor capacitySpeed 20 to 80 bottles per minuteLength 1000mmWidth 700mmHeight 1000mm

Packaged Drinking Water Filling Machine

108,000 Per Piece

1 Piece(s) (MOQ)

Our Packaged Drinking Water Filling Machine comes with a weight of only 200 kilograms. Customers can contact us for obtaining superior grade Packaged Drinking Water Filling Machine at the most competitive prices. We are a name synonymous to trust and quality, thus we make every attempt to bring forth only finest product range that is manufactured using premium quality range of products.

Bottle Filling Equipment

25,000 Per Piece

Water Chilling Plant

Get Price Quote

Our Water Chilling Plants are energy efficient and environment friendly. They are in high demand with our clients. The equipment is used for removing heat from water. Highly reliable, our Water Chilling Plants are used in various commercial, industrial & institutional establishments. These Water Chilling Plants have a sturdy construction and require minimal maintenance. The Water Chilling Plants are reliable and deliver consistent performance. Our Water Chilling Plants are available to clients at economical prices. Usage : Air conditioning systems to transfer sensible & latent heat which results in cooling the air stream.Industries where these plants are required for controlled cooling of products, mechanisms and various types of factory machinery.To cool high-heat and specialized items such as MRI machines and lasers. Additional Usage In : Analytical equipmentChemical processingCompressed air and gas coolingDie-castingFood and beverage processingInjection and blow moldingMachine toolingMetal working cutting oilsPharmaceutical formulationPower generation stationsPower suppliesSemiconductorsVacuum systemsWelding equipmentX-ray diffraction

Mineral Water Packing Machine

300,000 Per Unit

water bottling equipment

Get Price Quote

Incorporates Rotary Rinsing - Rotary Gravi Filling and Rotary Screw-on Capping operations on a single base, Rinsing device uses neck grippers to invert the bottles for Rinsing and automatically unloads into the inlet turret of the Gravi Filling section in the upright position after Rinsing internally, Bottles once located in the Rinsing Station are released only after all the three operations (Rinsing - Filling - Capping) are over, Adequate neck holders provided at the Filling and Capping Stations to eliminate buckling of Pet Bottles, Universal Hopper provided for automatic Capping provided diameter of the caps is larger then its height, No bottle - No Rinse. No bottle - No Fill, No bottle - No Cap. Available in two models: RFC-L (with 16 jets Rinsing + 16 heads Filling + 8 heads Capping combinations) and RFC-S (with 8 jets Rinsing + 6 heads Filling + 6 heads Capping combinations), Can be adapted to Rinse, Fill and Cap bottles from 200 ml upto 2000 ml in a single stroke. Approximate output speeds of 24 bpm and 60 bpm for 1 litre Mineral Water Bottles on the above two models possible. Can also accommodate other sizes of bottles with the help of change parts on request.Can also be adapted for other applications like juices, squashes, etc. in Pet Glass bottles. Outputs will depend on volume of fill and type characteristics of liquid to be filled.