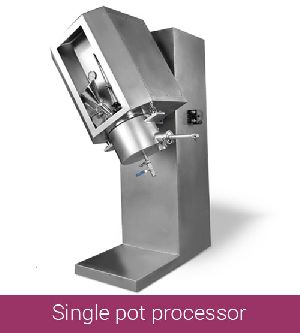

single pot processor

Scaling up based on design principles of Relative swept volume, Tip velocity and Impeller angle. Effervescent, potent & oncology drug processing through single equipment. Enclosed processing maintaining high safety standards to the user. Efficient sealing components for organic solvents working in process control. Enhanced uniform drying with Swinging Bowl feature. Drying in optional patterns of Vacuum or Microwave application. Substantially less transfer path during processing. Increased time efficiency in continuous productive usage of the equipment. Conceptual assembled components with rear access for easy maintenance.

...more

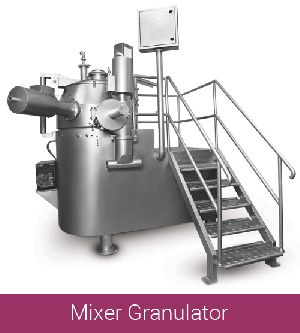

mixer granulator

Variant capacity model scale-up with equivalent Geometric, Kinematic & Dynamic similarities. Froude No., Tip velocity & Swept Volume functional parameter of design principles. Automated & Controlled solution dosing to enhance mixing pattern. Improved automation control & better safety interlocks for user's operation & safety. Clear visual inspection through all interior parts. Powder conveying integrated systems for material charging. Optional automated Lid opening and blade lifting operations.

...more

Integrated granulation suites

Minimal floor area consumption for installation. Quick product transfer & clean dust-free processing at reduced expenditure. Improved operating & safety standards for users. Effective cost saving in installation & operation. Suited for Potent Drug Formulation with use of advance techniques. Easy access to complete assembly for inspection & maintenance. Enclosed cleaning with advanced CIP/WIP systems. Overall improvement in operational quality with separate process & technical areas.

...more

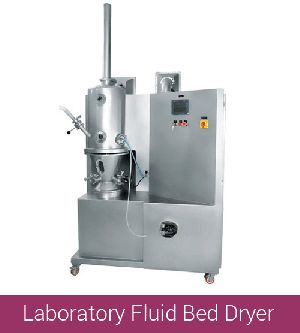

Fluid Bed Dryer

Multiple bowl option for drying & processing. Vertical Discharge transfer with actuated valve controlled sieve assembly. Top & bottom spray options available. Hepa Filtered & humidity controlled air for drying operation. Improved filter bag shaking system with air purging opetation HInged bowl system for easy maneuvering. Advanced WIP system with multiple dynamic wash points for thorough cleaning. Optional isolation valves provision for explosion suppression. Special 10 bar design as per product. Multiple bowl options possible. With Variable frequency drive for pressure and CFM control. Mobile units or table top model options. Adaptable for granulator options. Skid mounted unit. Smallest capacity possible is 300ml

...more

Conta Blender

Co-Mill

Design principle & variant capacity model scale-up with equivalent tangential speed. Multiple shaped impeller to suit process requirement for transmission of low shear, high shear and compressible force for sieving. Output to suit PSD requirement of products. In-line provision or mobile units as per operational requirement. High precision manufacturing standards in SLE & Grater sieves.

...more

Co Mill

Design principle & variant capacity model scale-up with equivalent tangential speed,Multiple shaped impeller to suit process requirement for transmission of low shear, high shear and compressible force for sieving,Output to suit PSD requirement of products,In-line provision or mobile units as per operational requirement,High precision manufacturing standards in SLE & Grater sieves

...more

Rapid Mixer Granulator

Cone Mill Model

Laboratory Mill

Be first to Rate

Rate ThisOpening Hours