Vibro Sifter

Vibro sifter are circular unitary gyratory screens used to separate mass composition of solids from solids, liquid from solid and for gradation of materials as per particle size, having a very wide range applications. Portable and compact. Electric power requirement less than other machine of the kind in the industries & lower energy. Consumption compared to reciprocating vibratory system. Standard machine are with TEFC motor explosion proof FLP motor. Easy dismantling and cleaning facility for contact parts.

...more

Transfer Pump

We are manufacturers of following Ointment Transfer Pump machineries:

...more

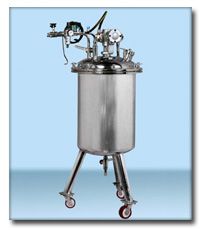

Storage Vessel

Application : To store the final product in Storage Vessel.

Capacity : As per users requirement.

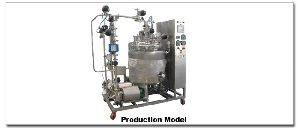

Spray Coating Machine

This is conventional and complete system to connect any Coating pan and most suitable for the rapid and uniform coating of Tablets, Granules & Pallets. The system consists of a stainless steel 316 quality pressure vessel provided with S .S. jacket with electric heaters and thermostat control and provided with safety valve, pneumatic oscilating type stirrer fitted on top of the vessel.

...more

Pure Steam Generator

APPLICATION : Used for Sterilization of vessel / Pipeline / Reactors & Inner chamber of Autoclave. CAPACITY : 50 to 1000 Kg./hr. TECHNICAL SPECIFICATION : Purified water with max. conductivity of 0.5 micromhos/cm. should be used. Pressure should be 1 kg/cm.sq. higher than the in feed steam pressure. Temperature Ambient 30ºC. Outlet of clean steam pressure 3 kg./cm.² OPERATION : To produce pyrogen free sterile steam confirming to IP/BP/USP specification. Endotoxing less than 0.25eu/ml Low maintenance cost. FEATURES : Fully Auto control panel with Touch screen online conductivity for Feed water & outlet of Pure steam. All tubes are seamless pipes / Electropolish. TOC – 100 PPB. All gaskets are Teflon. Imported pumps. ADVANTAGES : To sterilize Vessel /Pipelines/Fermentator without dismantling and movement.

...more

Pure Steam Generators

technical specification : purified water with max. Conductivity of 0.5 micromhos/cm. Should be used. pressure should be 1 kg/cm.sq. Higher than the in feed steam pressure. temperature ambient 30ºc. outlet of clean steam pressure 3 kg./cm.² operation : to produce pyrogen free sterile steam confirming to ip/bp/usp specification. endotoxing less than 0.25eu/ml low maintenance cost. features : fully auto control panel with touch screen online conductivity for feed water & outlet of pure steam. all tubes are seamless pipes / electropolish. toc – 100 ppb. all gaskets are teflon. imported pumps. advantages : to sterilize vessel /pipelines/fermentator without dismantling and movement.

Capacity : 50 to 1000 Kg./hr.

...more

Oral Manufacturing Machinery Unit

PLANTS CONSISTS OF : Sugar Dissolving Vessel. Manufacturing Vessel. Holding Vessel. Online Sugar Syrup Pre Filter Vacuum System for Transfer of Sugar & Sugar Syrup Zero Holdup Filtration Unit. Inline Homogeniser. Inter connecting vessel / Sugar Suction Pipeline TECHNICAL SPECIFICATION : Complete vessel design as per ASME guideline. Vessel design & fittings are designed for CIP Sanitizable. Bottom entry propeller agitators with specially designed cartridge mechanical seal. Complete closed type. FEATURES : Sugar Syrup and Manufacturing vessels are designed for internal vacuum to facilitate transfer of sugar directly from stores to sugar syrup vessel. Sugar granules transferred by vacuum system from dispensing room with highly Electro polished pipeline. NO Vibration of shaft. NO coupling in the drive assembly. Leading to lower maintenance cost. Final Product transfer through Zero hold up filter press in to storage vessel. Storage vessel is also a closed type vessel having stirrer for suspension. ON Line Homogeniser for Suspension products. ADVANTAGES : Designed in accordance with cGMP requirements. The plant is designed to be operated by one operator and helper. Saving on precious man power costs. No Human Touch any where up to Filling Machine hopper.

Capacity : 1000 to 20000 Ltrs.

Application : Liquid – Oral Manufacturing Plant is designed as per present cGMP requirements to manufacture

...more

Ointment Plant

By Manual Control OR By auto Control (Optional) Manual Control – Have temperature indicator Timer Push Button for operate the complete plant. Auto Control – PLC based with Touch screen and password level to feed the parameters of process for Heating Cooling Stirrer timingHomogeniser Timing Stirrer speed Homogeniser speed Vacuum Pressure CIP etc. RECIPE SYSTEM : To stored processed parameter to give high batch to batch consistency. MMI (Touch Screen) for visualization of machines of specific process condition and data.

Capacity : 25 to 3000 Kgs.

...more

Ointment Mixer

By Manual Control OR By auto Control (Optional) Manual Control – Have temperature indicator Timer Push Button for operate the complete plant. Auto Control – PLC based with Touch screen and password level to feed the parameters of process for Heating Cooling Stirrer timingHomogeniser Timing Stirrer speed Homogeniser speed Vacuum Pressure CIP etc. RECIPE SYSTEM : To stored processed parameter to give high batch to batch consistency. MMI (Touch Screen) for visualization of machines of specific process condition and data.

...more

Ointment

TECHNICAL SPECIFICATION : Semi Contra design agitator with blades having holes to cut the mass. Jacket have heating & cooling with temperature controller. Separate vessel for wax melting & water heating. Process piping are highly Electro polished and joints are DIN / TC standard for easy opening & re-fixing. Hydraulic Power Pack with cylinder to lift complete agitator assembly with top lid for product recovery / Easy to cleaning / Change over of batch & for maintenance. VFD for Anchor agitators to vary the RPM as per product / Recipe. Cleaning validation by SWEB testing match international standard less than 10 PPM OR by CIP system with online conductivity. Imported gear box with synthetic oil (Zero noise level) Load Cell for accurate weighing of final products. Watering vacuum pumps to create vacuum in Mfg. vessel and transfer other ingredients Molten wax / Hot water in Mfg. Vessel. Vacuum system save timing to transfer product from one vessel to another vessel and zero retention in pre phase vessel & inter connecting pipeline. To remove Air enter peal from the product. No Air contamination./ Human contamination. FEATURES : By Manual Control OR By auto Control (Optional) Manual Control – Have temperature indicator /Timer / Push Button for operate the complete plant. Auto Control – PLC based with Touch screen and password level to feed the parameters of process for Heating / Cooling / Stirrer timing/Homogeniser Timing / Stirrer speed / Homogeniser speed / Vacuum / Pressure / CIP etc. RECIPE SYSTEM : To stored processed parameter to give high batch to batch consistency. MMI (Touch Screen) for visualization of machines of specific process condition and data. FEATURES : Vessel design as per ASME guideline and tailor made design as per user’s requirements. Vessels are vacuum withstand to transfer product from one vessel to another vessel. (No chance of contamination)Homogeniser : - Mounted from bottom of the vessel in vertical and inclined position to homogenize the product & emulsify the oil & water minimal time with recirculating and same will be discharge to holding vessel.Anchor Stirrer : - Low speed special design with “W” shape with self adjustable Teflon scrapper & 2 Nos. stationery baffles to ADVANTAGES : Mixing , dispersing and homogenizing in one operation. Homogenous product consistency without trapped air bubbles. Large variety of products due to the highly flexible dispersing and homogenizing system. Fast product change over. Sterile production corresponding to GMP regulations. Rapid and effective cleaning : CIP / SIP High capacity with minimal space requirement. Simple operation. Can be fully automated. Integration into existing process control system.

...more

Octagon Blender

To blending and mixing of Dry Powders Granules and Crystals like Colors, Pigments, Minerals, Dyes, Flour, Grain, Ceramics, Detergents and other food, Pharmaceuticals & Chemicals powders.It is easy to clean and is available in wide range of specifications. The conical shape at discharge for easy discharge and no retention. Safety guards with interlocking system. All moving parts covered with S. S. 304 cover.

...more

Multi Column Distilled Water Plant

APPLICATION : To generate WFI water for injection / Large volume of Parenteral. CAPACITY : 50 to 2500 Ltrs. TECHNICAL SPECIFICATION : Distillate - IP/BP/USP specifications compliance. Distillate Temperature 95ºC Conductivity : Less than 0.5µ Siemens/cm. Endotoxing – Less than 0.25 Eu./ml. TOC – 100 PPB FEED WATER Purified water with max. conductivity of 0.5 micromhos/cm. should be used. Pressure should be 1 kg/cm² higher than the in feed steam pressure. Temperature – Ambient 30ºC COOLING WATER Normal tap water is used Provided hardness is less than 90 PPM of CaCo3. Temperature – Ambient 30ºC STEAM Steam must be saturated, dry free from oil, vapors and other impurities.(A steam filter to obtain 3µ, clear quality steam is recommended ask for details) Pressure –min steam pressure of 3 kg./cm² is essential to guarantee pyrogen-free distillate. OPERATION : To feed purified water & heat with boiler steam & generate clean steam and condense with cool water which is WFI. FEATURES : Energy Saving - Low operating cost. Compact Design - Space saving. All contact parts are S. S 316L and all joints are sealed with Teflon Gasket. Fully Automatic operation - No Attendant required. ADVANTAGES : Save water consumption & Boiler steam consumption. Complete close loop system. No air contamination. On line conductivity. If sub standard conductivity will come dumping automatically through 3 way valve

...more

Magnetic Mixer

TECHNICAL SPECIFICATION : Complete vessel design as per ASME Code. Instrumentation & connections comply with BPE & EHEDG guideline. Vessel design & fittings / Stirrer are designed for CIP / SIP able. OPERATION : Complete aseptic design with Magnetic mixer & high shear Magnetic emulsifier. Zero dead leg aseptic design Flush bottom outlet diaphragm valve with SIP able. Sampling valve zero dead leg type with CIP/SIP able. Volume monitoring by Load Cell. PH Sensor / Conductivity Sensor provided on demand for online check Product PH & Conductivity. ADVANTAGES : Free and clean working area around the charging port. Variable speed drive allows to control of mixing speed while batch preparation. Designed in accordance with cGMP requirements for CIP and SIP. Mixing head designed for vigorous mixing or low volume blending. Magnetically powered drive, NO SEALS / NO SHAFT thereby eliminating contamination. Easy removable of drive unit.

Capacity : 20 to 10000 Ltrs.

...more

Liquid Oral Manufacturing Plant

Liquid – Oral Manufacturing Plant is designed as per present cGMP requirements to manufacture Oral Liquid Suspension etc.Sugar Syrup and Manufacturing vessels are designed for internal vacuum to facilitate transfer of sugar directly from stores to sugar syrup vessel. Sugar granules transferred by vacuum system from dispensing room with highly Electro polished pipeline. NO Vibration of shaft. NO coupling in the drive assembly. Leading to lower maintenance cost. Final Product transfer through Zero hold up filter press in to storage vessel. Storage vessel is also a closed type vessel having stirrer for suspension.

Capacity : 1000 to 20000 Ltrs.

...more

Liquid Filtration Unit

OPERATION : The liquid to be filtered is forced in the chamber by the Transfer pump, where it finds its way to the top of the filter media of each plate through circular opening on the side of the plates. Under pressure clear Liquid passes through the filter media leaving suspended particles on top of the filter. The clear filtrate runs down through central channel formed by the interlocking cups and exists through the outlet valve. FEATURES : Single pass clear filtration.Full batch recovery of the filtrate. Easy install inside cartridge assembly.Complete cake retains on the plate. Uniform distribution of cake on each plate. Reduce the cost of treatment of catalyst, Toxic Chemicals. Less exposure to the operating person. No contamination of the internal surface of the shell. ADVANTAGES : Zero retention in filter vessel. APPLICATION : To filter final product in Pharmaceuticals, Perfumes, I. V. Fluids, Dyes & Chemicals, Activated carbon, Pesticides, Cosmetics, Varnishes, Polymers, Resins & Paints, Sugar syrup, Food, Plant Water Polishing, Fruit juice, Soft drink, Beer & Liquors, Edible & Non Edible oils. SIZE AVAILABLE : 8” / 14” / 15” / 24” & 33” dia. TECHNICAL SPECIFICATION :

...more

Injectable Sterilization-in-Place

TECHNICAL SPECIFICATION : Completely Automated process cycles with PLC. Online display of process parameters with P & I of operating system with Touch Screen. Display of fault messages. SIP is designed in accordance with ASME BPE and EHEDG guidelines. OPERATION : To sterilize Fermentator / Reactors & Holding vessel / Pipeline in Sterile area Without dismantling. FEATURES : Supervisory access code prevents unauthorized changes and operation. Automated values for pure steam and sterile air. Vacuum pulsing cycles for validating vessel integrity. ADVANTAGES : Validatable process for sterilization of process equipment.Lower facility operating costs. Minimal dismantling of equipment and piping. Process vessels need not be autoclaved.

...more

Injectable Sterile Mfg. Vessel

CAPACITY : 20 to 10000 Ltrs. TECHNICAL SPECIFICATION: Complete vessel design as per ASME Code. Instrumentation & connections comply with BPE & EHEDG guideline. Vessel design & fittings / Stirrer are designed for CIP / SIP. OPERATION : Complete aseptic design with Magnetic mixer & high shear Magnetic emulsifier. Zero dead leg aseptic design Flush bottom outlet diaphragm valve with SIP able. Sampling valve zero dead leg type with CIP/SIP able. Volume monitoring by Load Cell. PH Sensor / Conductivity Sensor provided on demand for online check Product PH & Conductivity. ADVANTAGES : Free and clean working area around the charging port. Variable speed drive allows to control of mixing speed while batch preparation. Designed in accordance with cGMP requirements for CIP and SIP. Mixing head designed for vigorous mixing or low volume blending. Magnetically powered drive, NO SEALS / NO SHAFT thereby eliminating contamination. Easy removable of drive unit.

...more

Injectable - Clean-in-Place

TECHNICAL SPECIFICATION : Compact system User definable parameters. Online viewing of process parameters on display. OPERATION : CIP is the process used to ensure that process lines, vessels and reactors are free of inorganic and organic contaminants. Auto Printing of process parameters. FEATURES : Fully Automated, PLC controlled with touch screen display. Integrated validation and automated monitoring system. Multilevel Authorization password logins. Faults messages displays. ADVANTAGES : Design and fitted to clean 100% of the machine. Cleans areas normally un accessible on a manual sanitation. Reduce production downtime and faster than manual cleaning. Online validation with PH / Sensor & Final wash with Conductivity sensor.

...more

Inhealer Manufacturing Vessel

TECHNICAL SPECIFICATION : Vessel design as per ASME SEC-VIII, DIV-I Pressure vessel with Agitator. Zero dead legs valve for outlet. Rapture disc for pressure safety. Mechanical seal for stirrer to withstand high pressure. Special design hopper for Powder charging. Pneumatical operated lifting arrangement. Special gasket / “O” Ring compatible with product. Complete FLP design. OPERATION : Complete manual operation with FLP Panel (Auto – Operation on demand.) FEATURES : Minimum stirring agitator with high pressure.Vessel is CIP / SIP able.

Capacity : 10 to 500 Ltrs.

Application : Used for HFA type product for Inhealer / Air Freshner.

...more

Dry Heat Sterilizer

APPLICATION : Used to store WFI (Water for Injection) at 85 to 90ºC. Temperature.In Closed loop. CAPACITY : 100 to 10000 Ltrs. (Above capacity on demand) TECHNICAL SPECIFICATION : Design as per ASME guideline and user requirement. No stagnant point to avoid bacterial growth. Electro polish from inside. Insulation with SS 304 welded cladding. All contact parts will be of SS 316 / SS 316 L quality. 0.2 µ Hydrophobic Air vent filter for Air venting. OPERATION : To keep WFI at 85ºC. to 90ºC. in close loop with recirculation pump. FEATURES : Vessel is CIP/SIP able.Capacitance type level indicator for water level.Sanitizable pump for loop & recirculation.

...more

Distilled Water Plant

Purified water with max. conductivity of 0.5 micromhoscm. should be used. Pressure should be 1 kgcm² higher than the in feed steam pressure. Temperature – Ambient 30ºCSave water consumption & Boiler steam consumption. Complete close loop system. No air contamination. On line conductivity. If sub standard conductivity will come dumping automatically through 3 way valve

...more

Distilled Water Machine

Design as per ASME guideline and user requirement. No stagnant point to avoid bacterial growth. Electro polish from inside. Insulation with SS 304 welded cladding. All contact parts will be of SS 316 SS 316 L quality. 0.2 µ Hydrophobic Air vent filter for Air venting.Vessel is CIPSIP able. Capacitance type level indicator for water level. Sanitizable pump for loop & recirculation.

...more

D.M Water Storage Tank

APPLICATION : To sterilize the Vials / Ampoules / Large parenteral bottles. SIZE AVAILABLE : Tailor made (As per Customer’s requirement) TECHNICAL SPECIFICATION : Complete unit made out of S. S. 304. Double door with diagonally tightening lock and silicon gasket. Interlocking arrangement and indicating lamp provided. S. S. Tubular heaters. Temperature – up to 300ºC. Air circulation – Blower with hepa filter. Hepa pressure module provided in air suction line. Inlet / Outlet damper valve are pneumatically operated. OPERATION : After washing vials / Ampoules to load it in a boxes & place on carriage.Heat at settable temperature and cooled down with Hepa Pressure module. FEATURES : Fully Stainless steel model. Double door with pneumatic interlock. PLC based Control panel with 8 point temperature. Timer for Heating / Cooling. Printing port for feed & actual process data printing. 3 Separate password for operations of panel. ADVANTAGES : Special arrangement of baffles is made for the uniform distribution of air inside the chamber. Pneumatically operated 100 % sealed dampers. Silicon door gasket to ensure zero leakage during the operation. No black partical generate in the chamber due to install high temperature Hepa filter in inner chamber of DHS.

...more

Cream Manufacturing Plant

ECHNICAL SPECIFICATION : Semi Contra design agitator with blades having holes to cut the mass. Jacket have heating & cooling with temperature controller. Separate vessel for wax melting & water heating. Process piping are highly Electro polished and joints are DIN / TC standard for easy opening & re-fixing. Hydraulic Power Pack with cylinder to lift complete agitator assembly with top lid for product recovery / Easy to cleaning / Change over of batch & for maintenance. VFD for Anchor agitators to vary the RPM as per product / Recipe. Cleaning validation by SWEB testing match international standard less than 10 PPM OR by CIP system with online conductivity. Imported gear box with synthetic oil (Zero noise level) Load Cell for accurate weighing of final products. Watering vacuum pumps to create vacuum in Mfg. vessel and transfer other ingredients Molten wax / Hot water in Mfg. Vessel. Vacuum system save timing to transfer product from one vessel to another vessel and zero retention in pre phase vessel & inter connecting pipeline. To remove Air enter peal from the product. No Air contamination./ Human contamination. FEATURES : By Manual Control OR By auto Control (Optional) Manual Control – Have temperature indicator /Timer / Push Button for operate the complete plant. Auto Control – PLC based with Touch screen and password level to feed the parameters of process for Heating / Cooling / Stirrer timing/Homogeniser Timing / Stirrer speed / Homogeniser speed / Vacuum / Pressure / CIP etc. RECIPE SYSTEM : To stored processed parameter to give high batch to batch consistency. MMI (Touch Screen) for visualization of machines of specific process condition and data.

Capacity : 25 to 3000 Kgs.

...moreBe first to Rate

Rate ThisOpening Hours