33 Inch Zero Hold Up Sparkler Filter Press

160,000 - 500,000 Per Piece

1 Piece (MOQ)

CENTRAL FEEDING OF UNFILTERED LIQUID ENSURES : SINGLE PASS CLEAR FILTERATION. FULL BATCH RECOVERY OF THE FILTERATE. NO SCAVENGING OF THE FILTERATE. COMPLETE CAKE RETAINS ON THE PLATE. UNIFORM DISTRIBUTION OF CAKE ON EACH PLATE. REDUCE THE COST OF TREATEMENT OF CATALYST, TOXIC CHEMICALS. LESS EXPOSURE TO THE OPERATING PERSON. NO CONTAMINATION OF THE INTERNAL SURFACE OF THE SHELL.

Sparkler Filter Press

2 - 18 Per 1

1 Piece (MOQ)

Best Deals from Cast Iron Filter Press

Pre Seasoned Cast Iron Paniyaram

Get Price Quote

100 Piece (MOQ)

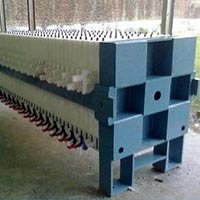

Recess Type Filter Press

Get Price Quote

1 Pieces (MOQ)

TRIMURTI FILTER PRESSES are well known for their up-to-date design, sturdy construction, and easy operation. These are largely used by chemical and Sugar factories and especially by OIL MILLING INDUSTRY for producing a first-class filtered oil and also saves an enormous loss of time and space required for the oil to settle down in tanks. These are prepared in two types :(1) Recessed Types(2) Flush Plate and Distance Frame Type. RECESSED TYPE The plates in this type are recessed so that when two plates are closed together, a chamber is formed. Each plate has a center feed hole and the faces are cast with pyramid type indentations to increase the filtering area. Filter cloth is placed on each plate and fastened back to the plate with hollow clips. When the press is closed, the cloth forms a tight joint between the machined edges of the plates. The liquid to be filtered is pumped into the press to fill up the chamber formed by the plates. The liquid is then forced out through the cloth, to the passage at the base of the plate, and hence to a trough through bib cocks. FLUSH PLATE AND DISTANCE FRAME TYPE In this type, the machined edges are almost at level with the indentation surface. A separate form is used between them to form the chamber. The cloths are not fastened in any way to the plate, but only hang over the frame and nipped between the edges of the plates and distance frames, when these are closed together. The filter cloth is thus easily renewed for cleaning. The thickness of the frame determines the depth of the chambers. The type is recommended for filtering oils with the use of filter aids, such as fullers earth, Kieselguhr, or activated carbon. STANDARD EQUIPMENT These are supplied with suitable belt-driven on motorized pumps. Standard equipment also includes the necessary safety valve air vessel, pressure gauge, out, et cocks trough, etc. Filter cloth bags are supplied at extra cost.

Filter Press

Get Price Quote

We offer an impeccable quality of Filter Press. Our Filter Press is extensively used in various industries for the efficiency, durability and reliability it provides. Our Filter Press is use for filtration of material containing solvent. We offer our Filter Press in various different types and specifications to cater our client�s extensive needs. Further, our Filter Press is ideally priced. Types Simple Filter PressMembrane Filter PressRecess type Applications BreweryDyesPigmentMineral oreChina ClayPurification & disposal of sewage industrial Mining effluents

Filter Press Machine

150,000 Per Piece

1 Piece (MOQ)

Membrane Filter Holder

4,520 - 9,020 Per Packet

100 per packet (MOQ)

Automatic Hydraulic Press Machine Manufacturer Maharashtra

100,000 - 500,000 Per piece

1 Piece (MOQ)

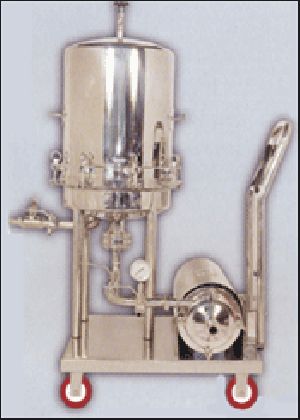

Zero Hold Up Sparkler Filter Press

350,000 - 1,200,000 Per Piece

1 Piece (MOQ)

Description: Sparkler Filter Press is a filtration machine used to filter liquid in pharmaceutical, chemical, beverage, and other industries. Filter Press works on the principle of pressure feeding. Features: Due to the reverse flow of liquid, there is zero hold up in the filter press that leads to complete filtration of the batch. A backwash can provide a facility for continuous operations. No scavenger arrangement is required. The cake, filter aid & solids remain enclosed, allowing filtration of toxic, hazardous & explosive liquids. The top dome structure ensures fast & easy removal of cartridge assembly & cleaning of cake. We can increase the number of plates as per toxic levels of input or filtration requirements.

Plate and Frame Filter Press

Get Price Quote

* Provided with dip tray * By pass plate can be provided for pre & final filtration * Provided with mechanical closing device wherever required

Zero Hold Up Filter Press

Get Price Quote

cGMP Zero Hold-Up / Sparkler Type Filter Press consist of Stainless Steel Shell & Top cover using bolts to give pressure tight enclosure. The filter cartridge assembly inside the shell consists of several horizontally arranged disc type filter plates with perforated supporting screens, filter media & interlocking cups. The entire assembly complete with pump & piping connection is mounted on a suitable S.S. Trolley. Details : Single pass filtration with no solid bypass. Full batch recovery, no separate scavenging system needed. Proper sealing which allows the filtration of volatile, toxic and inflammable products. Plate pack arrangement ensures any type of filtering media singularly or in combination, can be used to achieve required micron efficiency. Easy removal and cleaning of the cartridge assembly. Closed System ensures filtration of toxic, hazardous, explosive materials, efficiently cleaned and sterilized. Central feeding ensures no solid inside the vessel, complete recovery of liquids. Uniform filter-aid bed can be formed. Jacket can be provided for hot filtration & cooling Available model 8", 14", 18", 24" & 33". Available with centrifugal / gear / lobe pump.

SS Filter Press

Get Price Quote

We manufacture stainless steel filter presses which are used in specific applications like food grade applications where no contamination is permissible. Similarly we also manufacture cast iron and aluminium filter presses that are used for applications wherein temperature and viscosity constraints do not allow use of polypropylene plates.

Zero Hold Up Filter Press

Get Price Quote

We are offering excellence in the form of Zero Hold Up Filter Press to enhance the buyers' content. We have an in-house facility, which is used for making stocks. Laced with modern amenities, our storehouse keeps the products away from moisture, rainwater, sunlight, etc.Details : Sizes available 8”, 14”, 18”, 24” & 33” Diameter MOC SS 316 / 316L. Available models 8”, 14”, 18”, 24” & 33” plate diameter. Available with centrifugal / gear / lobe pump. Fitted with pressure gauge, safety valve & airvent. cGMP with documentation.

Plate & Frame Filter Press

Get Price Quote

Being a customer-oriented firm, we make available numerous modes of payment and assure them for confidentiality of transaction. Also, our payment modes are authorized. The quality analysis system, we have, is headed by a pool of professional quality experts having rich domain experience. Features: Energy efficient User-friendly High productivity

Zero Hold Up Filter Press

Get Price Quote

We are offering highly efficient Zero Hold Up Filter Press that is widely used in different applications like fine chemicals, food industries, pharmaceutical, polymers, perfumes, etc. Our Zero Hold Up Filter Press fulfills all the demands of the filtrations. We make available Zero Hold Up Filter Press in different size range and construction material in order to meet the requirements of the clients. Operation The plate pack assembly consists of plates with interlocking cups, plate rings, perforated screens and filter media. Interlocking cups arranged one above other forms single pipeline. The unfiltered liquid is centrally fed under pressure from bottom inlet. The liquid spreads out equally on each plate fitted with filter media. Solids remains on the filter media and clear filtrate flows through gaps on the supporting rings and collects in the shell, which is led out through outlet pipeline. In this process, solids are evenly distributed on each plate. At the end of the cycle the cake can be maximum dried by applying air or inert gas. The liquid to be filtered is pumped to the tank, where it enters into the individual plates. It passes through the filter media (Paper/Cloth) and crystal clear filtrate comes out through a central channel formed by interlocking cups. The cake formed between the plates can be obtained if required. The Cartridge assembly consists of plates, perforated screens, spacers and fitter media. Interlocking spacers internally form single pipeline. The unfiltered liquid is centrally fed under pressure from bottom inlet. The liquids spreads out equally on each plate fitted with filter media. Solids remain on filter media and clear. filtrate flows through precisely made holes on sides of plates and collects in the shell, which then comes out through the outlet. In this process, solids are evenly distributed on each plate. The cake is then cleaned from the filter material and used again for filtration process. Single pass filtration with no solid bypass Full batch recovery, no separate scavenging system needed. Proper sealing which allows the filtration of volatile, toxic and inflammable products. Plate pack arrangement ensures : Any type of filtering media singularly or in combination, can be used to achieve required micron efficiency.Easy removal and cleaning of the Cartridge Assembly. Central Feeding Ensures No solid inside the vessel complete recovery of liquids. Cake solids can be maximum dried with N2. Complete cake retains over the plate. Uniform distribution of cake on each plate. Uniform filter-aid bed can be formed. Reduces the cost of expensive solvents. Closed System Ensures Filtration of Toxic, Hardous, Explosive materials. Efficiently cleaned and sterilized.

Horizontal Filter Press

Get Price Quote

Before making the final dispatch, our entire lot is carefully stored in our capacious warehouse under the administration of experts. Thus, there are minimal chances of defects at buyer's end. We are a focused towards bringing forth exceptional array of products that are quality tested from the initial stages of manufacturing. Our quality inspectors inspect each and every element of the raw material with complete proficiency

Zero Hold Up Filter Press

90,000 Per Piece

We are instrumental in providing our clients a comprehensive range of excellent quality Zero Holdup Filter Press Manufacturer In India. Our complete range is designed with top quality of material in accordance with the market norms. Product range Alpro Equipments is a specialty of manufacturing and suppliers all kind of range Zero Holdup Filter Press. Alpro equipments has been actively involved in Zero Holdup Filter Press Manufacturer, which are widely used in Pharma, bulk drugs, distilleries, beverages & varies industries. we are supplier, export and zero holdup filter press manufacturer in india. our product are perform high with low maintance, alpro equipments team are expert to design and fabricate of best Zero Holdup Filter Press with industrial standard. Features of zero hold up filter press: Low noise operation. High output results. Consume less power. Description: Zero hold up Horizontal plate closed pressure filter that meets all the demands for a filtration which would discharge solid free filtrate. Design of filter press is according to cGMP & FDA approval. Other Details: Components are argon arc welded & polished to mirror finish SS jacket can be provided for hot filtration. (Optional) Provides crystal clear filtration by filtering particles up to 1 micron size. No Scavenger arrangement is required No liquid between the tank & the cartridge Top dome structure ensures fast & easy removal of cartridge assembly & cleaning of cake Uniform filter aids & cake distribution SS pump mounted on SS trolley with heavy duty trust ball bearing caster wheels for easy movement Provided with different types of pumps depending on the viscosity of liquid & output i.e. Centrifugal pump, Gear Pump, Lobe Pump, Roto Pump Etc Provided with bypass system, safety valve & sample collecting device No contamination of internal surface of the shell Horizontal plate Zero Hold Up filter press is constructed in such a manner that it prevents evaporation,Oxidation, Leakage & Fumes escaping from product Plates are available in two sizes: Deep plate for higher percentage of caking holding capacity & shallow plate for lesser percentage of cake holding capacity Filter plate & thickness of cake prevents the cake dropping as well as cracking, thus assuring better filtrate quality According to requirement filtration area & cake holding capacity can be increased or decreased

Filter Press

Get Price Quote

We are offering filter press. Economical a filter press is a highly efficient, compact, dewatering device for separating solids from liquid slurries in the form of compressed cake. Its major components are a structured framework, filter chambers.

Filter Press

Get Price Quote

We among the most trusted firms, indulge in manufacturing, supplying and exporting Sparkler Filter Press. Used in several industries like automobile, automotive and textile, these products are made using quality material and latest technology. Our Sparkler Filter Press is also thoroughly checked by expert quality controllers on various parameters to ensure flawlessness. We further conduct regular researches for improvising these products.

Zero Hold Up Filter Press

Get Price Quote

We are offering zero hold up filter press. Features of zero hold up filter press : * range : 8" dia x 8 plates to 24" dia x 24 plates * material : ss 304 & ss 316 * jacket for heating can be provided as option * suitable pump with motor * entire filter press assembly is skid mounted for easy handling * cgmp finish

Filter Press

Get Price Quote

We offer filter press. Kumar filter press kumar filter press are very popular throughout the country and abroad in view of its quality and workmanship coupled with our long standing experience. These filer press are used in oil mills and also in the chemical industry. We manufacture quality cast iron filter press and are available with rachet type tightening. plate type size inches filtering area pump h. P. Required 30" x 30" x 40 plates 360 7.5 30" x 30" x 30 plates 240 5 30" x 30" x 25 plates 200 5 25" x 25" x 36 plates 140 3 25" x 25" x 30 plates 120 3 25" x 25" x 25 plates 100 3 18" x 18" x 18 plates 40 2 plate & frame type size inches filtering area pump h. P. Required 15" x 15" x 15 plates 25 7.5 12" x 12" x 12 plates 12 5 25" x 25" x 25 f24p 180 5 30" x 30" x 20 f19p 200 3 30" x 30" x 25 f29p 120 3 30" x 30" x 30 f24p 100 3 salient features cast iron, short blasted plates leads to easy flow of filtered oil without spillage under pressure. leakproof joints to withstand operating pressure high grade c.i. projected edges of the plates form a very good filtration chamber which will help for a very efficient filtration capacity. high rate of filtration powerful pump and accurate assembly machined and well furnished taped edges of the frame also stop spillage of oil under pressure and assure long life of the cloth.

Pp Filter Press

Get Price Quote

Filter Press Machine

115,000 Per Per Machine

1 Piece (MOQ)

Salient Features: Horizontal Plate Filter Press is enclosed construction, preventing evaporation, oxidation, leakage and fumes escaping from product Filter plates are available in two sizes. Deep plate for large percentage of cake holding capacity and Shallow plate for small percentage of cake holding capacity The horizontal filter plate and even thickness of cake, prevent the cake dropping as well as cracking, thus assuring better filtrate quality The Filtration area and cake holding capacity can be increased or decreased according to equirement

Filter Press

Get Price Quote

The unfiltered liquid is fed into the filter under positive pressure, where liquid travels in downwards direction and finds its way through opening on sides of the Filter Plates. As the liquid pressure increases, the Filter media holds the foreign particles and allows only clear filtrate to pass through the central channel formed by interlocking pressure cups to the outlet. Filtration is continued until the cake holding capacity of the unit is reached or until the filtrate rate becomes too slow owing to cake resistance. Innovative Features : • Horizontal Plate Filter Press is enclosed construction, preventing evaporation, oxidation, leakage and fumes escaping from product. • Filter plates are available in two sizes. Deep plate for large percentage of cake holding capacity and Shallow plate for small percentage of cake holding capacity. • The horizontal filter plate and even thickness of cake, prevents the cake dropping as well as cracking, thus assuring better filtrate quality. • The Filtration area and cake holding capacity can be increased or decreased according to requirement.

Zero Hold Up Filter Press

110,000 Per Piece

1 Piece(s) (MOQ)

Filter Press Machine

200,000 Per

Membrane Filter Holder

Get Price Quote

Sparkler filter Reverse flow Zero Hold up Filter

85,000 - 350,000 Per Each

Reverse flow filter with SS 316 MOC along with pump and motor mounted on trolley with all standard accessories. Plug and Play model with filter pads in Polypropylene

Filter Plate

Get Price Quote

type horizontal plate filters stack consists of multiple number of circular filter plates. Filter cloth or any other filter media is placed over each plate. The slurry mother liquor is pumped over the plates through the specially designed manifold. Filtration process is continued till the desired cut off pressure limit is achieved. Then, the cake is manually removed from each of the filter plate cavity.

Zero Hold Up Filter Press

Get Price Quote

Zero Hold Up Filter Press that we offer is precisely manufactured keeping in mind the set industry standards. Our Zero Hold Up Filter Press is subjected to stringent quality tests prior to its final dispatch. We are counted among the top Manufacturers and Suppliers of Zero Hold Up Filter Press. WE are efficient enough to process retail as well as bulk orders for Zero Hold Up Filter Press even at short notice period. Details : Manufactured in Ss-304 / 55-3161 55-3161 Quality, Argon Arc Welded and Mirror Polished. Ss Jacket Can Be Provided for Hot Filtration. It is Generally Used to Obtain Crystal Clear Filtration By Filtration By Filtering Particles Up to 1 Micron Size. It Can Be Provided with Different Types of Pumps I.e. Gear Lobe Centrifugal Pump, Depending On the Viscosity of Liquid and Output, Which Can also Be Used for Liquid Transfer. T.E.F.C. Flame Proof Motors Can Be Provided. Provided with Pressure Gauge, Safety Valve, Bypass System, Sampler, Air Vent & Drain System. Can Be Manufactured as per Customer Design Requirement. Cake Formed Between the Plates Can Be Obtained if Required. and Also, It (cake) Can Be Dried Either By Compressed Air or By Inert Gas, Steam. Complete Unit is Mounted On Ss Trolley & Fitted with Ss Bracket, Pu. Bond Castor Wheels for Easy Movement. Scavenger Plate Arrangement to Remove all the Liquid.