tube bending die

Get Price Quote

We manufacture press tools for sheet metal, tube MS & SS. Price of the tool depends on the part so please share your required drawing to get quote.

bullion marking dies

Get Price Quote

Molds "Hallmarking" marking ingots. Customizable with: • Company Name • Company logo • Title bar • ingot Weight

Best Deals from Casting Dies

Tin Container Die

50,000 Per Piece

1 Piece (MOQ)

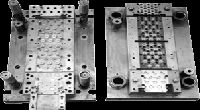

sheet metal stamping dies

1,320,000 Per Piece

blow mould die

500,000 - 1,500,000 Per piece

1 Piece (MOQ)

Cutting Die

350 Per Piece

50 Piece (MOQ)

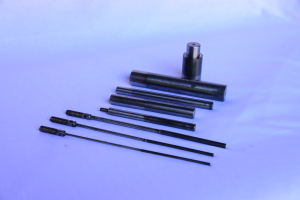

tungsten carbide heading dies

Get Price Quote

Mikron engineers is committed to provide engineered wear solution through advance tungsten carbide material, innovative heading dies design technology and dedication to exceed our fastener industries� customer's expectation. We provide service in following fastener tooling.

Double Strand Die for PVC Pipe

Get Price Quote

Range 16mm-63mmUPVC tubing extrusion die structure adopts support type with reasonable designed roller track. Being specially treated, the support well-distributed flow of the materials and temperature of the melt. It is easy for disassembly and cleaning.

Thread Rolling Dies

10,000 Per Piece

1 Piece(s) (MOQ)

e have specialised in offering a diverse range of Thread Rolls Worm Shaft Rolling that is fabricated in accordance with the international quality standards. These worm shaft rolling thread rolls are available in various models and are widely used in varied industries. CNC lathes, milling machines, drilling presses, grinders, gear planners and tapping machines, electric tool transmission and automobile engines are some of the machines where our worm shaft rolling thread rolls are used.

tablet punches and dies

1,000 - 2,400 Per Piece

1 Piece (MOQ)

Tablet Press Tooling - Die & Punch Precise Perfect Finish Tablet Press Tooling Application & Process : ACE Punches and dies are manufactured in-house with state of art machines. The raw material used in the production of tablets is compressed by a pressure of several tons on a small area of a few square millimeters, to produce a visually perfect tablet. There fore the Tablet press tooling is required harder and smoother and good finish surface. Prism has developed an advance technological system especially for manufacturing of precise, perfect and finished tablet tools. Salient Features : Choice for material of construction of Die and Punch- 1. OHNS (T) Oil Hardened Non shrinking steel (Tungsten) - AISI 012. HCHC - High carbon High chromium steel - AISI D3 Tooling size as per EURO, IPT Standards and Special tooling. Can be manufactured any shape of the tooling. Can be manufactured Multi tips and Polo type tooling. Careful matching of material and hardness. Trouble free fitting and removal Manufactured to the smallest tolerances. High Precision finish. Tooling Set A single tooling set comprises of upper punch, lower punch and die. These punches move vertically in turret bores through cams and compress to form a tablet. As per international standards, i.e. TSM (Tablet Specification Manual) and EU (Euro Standard), tooling specs have been standardized so that inventories worldwide can be minimized for tablet presses. All international manufacturers follow EU standards and TSM standards mostly followed in the United States of America and in Japan. Upper punch: Upper punch is fitted in the turret bore and moves vertically in bores during compression. Upper punches make the upper cavity of the tablet. It is fitted with key for alignment with die bore in case of shape punches. For round punches, there is no need of key in upper punches. Upper Punches travels 5-6mm inside the die bore during compression and as per the penetration setting done in a compression machine. Tip Length is shorter in the upper punch compared to the lower punch. Tip length of upper punch is generally 8mm-9mm. Lower punch: The lower punch is fitted in the turret bore and makes the lower cavity of the tablet during compression. Lower punch tip always stays inside the die bore hence there is no need of key in case of lower punch. Tip length is relatively longer in the lower punch as it has to cover the entire height of die and eject the tablet. The lower punch tip length is 25-28mm. Die: Die is fitted in the die plate. Die bore in die is actually where the filling of powder is done. Upper punch tip and lower punch tip compresses the powder in the die bore with the help of compression roller pressure applied on the head flat during compression to make the required shape of the tablet. Tooling Types There are different types of tooling i.e. D, DB, B and BB types. Apart from these standard types, there are FS tooling, BBS tooling, A tooling and Chinese standard tools which are totally different than International standard tools.

Moulding Abrasive Wheels Carbide Dies

Get Price Quote

1 piece (MOQ)

Carbide Bush Fabricated By Shrink Fit Method And Core Pin Silver Brazed To Steal Body. These Caride Dies Are Used By Abrasive Wheel Manufacturers For Moulding Their Wheels. Carbide Dies For Forging And Cutting Can Be Manufactured As Per Customers Requirement.

Wire Drawing Die

2,000 Per Piece

100 Piece(s) (MOQ)

Dies

Get Price Quote

We are offering machinery & dies for cell bottoms tops.

Blister Forming Die

40,000 Per Piece

1 Piece (MOQ)

Dies and Tools

Get Price Quote

Dies are used in machine tools such as stamping presses or forging presses. Automobile tenders, coins and easy open can tops are some products processed by dies.

metal cutting press dies

Get Price Quote

metal cutting press dies, Hydraulic Pneumatic Expander System

carbide heading dies

Get Price Quote

We are eminent name in the manufacturer & exporter of burnishing tools, deburring tools, tungsten carbide, tungsten carbide bullets forming dies, laminated dies, heading dies, dry cell battery, tungsten, carbide rod, collapsible tube dies, spare parts for welding electrode, cold heating dies, forming punch. Also imports & supplies of tungsten carbide rod (unground) ( 5 to dia 20mm) & tungsten carbide rod.

casting machine jewelry

Get Price Quote

We are the main supplier of this product.

button die

450 Per Piece

threading dies

Get Price Quote

Specifications Totem Threading Die Nuts are best for cutting external threads manually. TOTEM Brand Threading Dies and Die Nuts are available in HSS and Cabon Steel materials. They are Ground Thread and Cut Thread Dies. ROUND DIES: Size : 1.6 mm to 100 mm or 1/8 " to 4" Outer Diameter : 16 mm to 125 mm or 13/16 to 5 " Types : Solid Dies ( Button) Split Dies Screw Adjustable Dies Thread forms : BSW/BSF/BSB/UNF/UNC/MM/BSP/BSCON/BSCY/BA/WF/ME/BSPT/NPT Direction : Left Hand or Right Hand Standards : BS1127/ DIN223/ IS1859 DIE NUTS Range : M3 to M 64 and 1/8 " to 2-1/2" Thread Forms : MM/BSW/BSF/UNF/UNC/BSP/BSP