Continuous Casting Machine

2,375,000 Per piece

Advantages: Perfect homogeneity of the alloys. Excellent casting even with low carat alloys and difficult sections thanks to the powerful pulling system with four rollers. High working speed thanks to the double cooling system of the die. Easy and fast setting and control by visual display unit. Certainty of maintaining the plant in good condition thanks to the self-diagnosing system and possible alarms with buzzer. Protection of crucible and die by argon or hydrogen gas. Protection of the melting chamber by aluminum casing easily and quickly removable to change the consumables. Crucible, die and thermocouples quick change for short set-up time. Pulling system with four rollers, stepper motor, closing and opening of the rollers with pneumatic control.

Pressure Die Casting Tools

Get Price Quote

Best Deals from Casting Machine

Automatic Foil Stamping and Die Cutting Machine

Get Price Quote

Vaccum Press Casting Machine

Get Price Quote

The fully automatic casting machine vc 450 this machine is designed for: • casting of jewellery and other filigree parts • for permanent use • for certified production processes constructed on base of the vc 400, the vc 450 is equipped with a completely new generator and a program control system with full read out lcd display. With help of the step-by-step display information and many automatic functions the handling of the machine is very easy even for less experienced users. The program control for 25 different casting cycles allow reproducible and consistent casting results. new program control system : new control panel with full text lcd display, all programs & parameters are very easy & convenient to set. 100 casting programs guarantee fast operation and consistent casting results. Parameters are pre programmed for all major alloys, e.g. For ags, aplha plus, heraeus, legor, and pandora alloys. In practice this mean: from the first flask, you can expect good casting results without carrying out expensive pretests. the comfortable lcd display and control system: 20 casting programs allow for the individual setting of relevant process parameters before casting and their storage for recurrent castings – which is important for quality certified processes, high process reproducibility and for an economical production with fast casting cycles. Performance power max. electrical connection maximum temperature capacity crucible volume for use of flasks up to handling+control maximum pressure program control dual temperature control automatic flask & chamber lift turbulence reduction software. quality management rs232, diagnostic system, remote service data printer gsm modern accessories sinrering kit (for dissusion bonding) granulation tank

Automatic Foil Stamping and Die Cutting Machine

Get Price Quote

Die Casting Machine

Get Price Quote

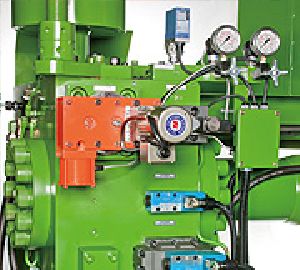

The V3C models are the most mature machines with the widest application range. They are also the most reliable and automated machines. Features: One piece design for the injection system The most efficient oil circuit with excellent injection performance. Integrated structural rigidity with self-lubrication design for long service time. Easy to install peripheral equipment for automation, which increases efficiency and saves man power. User-friendly Man-Machine Interface (MMI) with alarm device. Multi-stop injection adjustment provides a reduction of swelling gas in the barrel, while upgrading die casting product quality. There are three injection models including soft start with constant speed injection, constant acceleration injection and multi-stage injection for flexible production. The use of a P/F valve helps to increase convenience of operation while reducing electricity consumption up to over 15%. Available to be equipped with a servo controlled energy-saving electrical system for saving electricity consumption up to 50%. The Full Test function provides a simulation of die casting process that allows the operator to realize the aluminum liquid flow condition during a molding cycle.

Jainson Casting Crimping Tools

Get Price Quote

1 Piece (MOQ)

Vacuum Casting Machine

Get Price Quote

Since our inception year, we have been engaged in manufacturing and supplying high quality range of Jewellery Vacuum Pressure Casting Machine. This consistent, robust and easy to use vacuum centrifugal vacuum casting machines designed for small and medium casting laboratories. Under the observation of our adroit team, this is manufactured in compliance with set industry quality standards using optimal grade materials. Excellent in functionality, this can melt nonferrous and precious metals. Our clients can avail this Jewellery Vacuum Pressure Casting Machine from us at market-competitive prices.

Semi Automatic Large Format Die Cutting Machine

Get Price Quote

Semi Automatic Large Format Die Cutting Machine

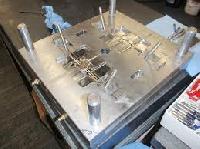

Pressure Die Casting Tools

Get Price Quote

Pressure Die Casting Tools, plastic die mould

Die Maker

Get Price Quote

Die Maker, Sheet Metal Component, Auto Electrical Parts

die makers

Get Price Quote

die makers

die making machine

Get Price Quote

die making machine, water filter moulds, industrial water filter moulds

aluminium sand casting machine

Get Price Quote

aluminium sand casting machine, Gravity die casting, transformers accessories

die makers

Get Price Quote

die makers

Casting Machine

Get Price Quote

Casting Machine, Automobile Components, Automobiles Parts

die moulding maker machinery

Get Price Quote

die moulding maker machinery, Alloys, steel ware, Injection Moulding