aluminium casting parts

Get Price Quote

With latest machines and technology, we ensure that the raw material used is as per the globally accepted standards and meet the international standards. We deliver the quality products that are manufactured using the best raw material. We make available a huge product basket that our quality auditors check closely to maintain the set standards.

Dies For Continuous Casting

Get Price Quote

Crack proof in nature, these Dies for Continuous Casting Machine are presented in the market in different sizes and shapes. These products are light in weight and safe from high pressure. In addition to this, these products are superior in quality and thick in frame and available in the market at minimal price. Features: Thick frame Quality tested

Best Deals from Casting Parts

Cast Iron CNC Machined Components

Get Price Quote

Pressure Vessels

Get Price Quote

Our expertise, methods & systems adopted for manufacturing of pressure vessels for any application is renowned in the industry. We have designed and manufactured vessels in Carbon steel, Alloy steels, Stainless steel and can also manufacture in any other special material on demand. We have supplied vessels up to 12 meters long and 6 meters in diameter, weighing up to 100 tons from design to fabrication. Quality and testing is assured as per TEMA, ASME Sec VIII and MSME/API etc.

LED PRESSURE DIE CASTING

Get Price Quote

we take this opportunity to introduce ourselves as a leading mould manufacturer, having presently a well-equipped precision tool room, which can cater to undertake design, development and manufacturing of various industrial plastic moulds, bakelite moulds, jig & fixtures, pressure die casting ,blow mould , street lighting , diffsuer ,impiller mould, automobiles part and tooling for industries.

Aluminium Gravity Die Casting

330 - 400 Per Kilogram

Pressure Die Casting Tools

Get Price Quote

JUMBO CLAMP

Get Price Quote

Most useful in making dining table. Helps in transportation of bulky items like dining table in Knock- Down condition.

Aluminum Die Casting

Get Price Quote

Acknowledged for its long service life, dimensional accuracy and sturdy construction, the offered Aluminum Die Casting is one of the supreme that is obtainable in the market. Professionals at our end are working with high-tech tools and modern machines for designing these products in tandem with set industry norms. Material which is been used in production process is of high quality which we have procured from certified vendors of the market. Features: • Dimensional accuracy• Sturdy construction• Resistant to corrosion

cast iron castings

Get Price Quote

These covers are manufacture concrete infill type, bolted, gasket and watertight and tamper proof manhole covers in grey iron and ductile iron. Cast iron casting components are casted with high precision for long lasting life.

Plunger Tip

6,500 Per Piece

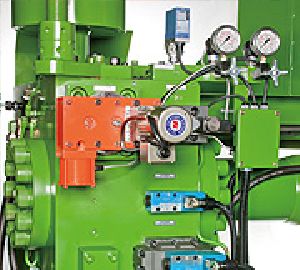

Die Casting Machine

Get Price Quote

The V3C models are the most mature machines with the widest application range. They are also the most reliable and automated machines. Features: One piece design for the injection system The most efficient oil circuit with excellent injection performance. Integrated structural rigidity with self-lubrication design for long service time. Easy to install peripheral equipment for automation, which increases efficiency and saves man power. User-friendly Man-Machine Interface (MMI) with alarm device. Multi-stop injection adjustment provides a reduction of swelling gas in the barrel, while upgrading die casting product quality. There are three injection models including soft start with constant speed injection, constant acceleration injection and multi-stage injection for flexible production. The use of a P/F valve helps to increase convenience of operation while reducing electricity consumption up to over 15%. Available to be equipped with a servo controlled energy-saving electrical system for saving electricity consumption up to 50%. The Full Test function provides a simulation of die casting process that allows the operator to realize the aluminum liquid flow condition during a molding cycle.

embossing dies

Get Price Quote

embossing dies

Plastic Dies

Get Price Quote

Plastic Dies, Plastic Moulds, Dies, Plastic Mold

Plastic Dies

Get Price Quote

Plastic Dies, Plastic Moulds

Zinc Pressure Die Casting

Get Price Quote

We undertake development of Customized Parts in sand castings, pressure die castings aluminum or zinc, forgings various steels by processes such as hammer forgings or press forgings. We also undertake development of plastic injection moldings. Alternately we also supply tools, dies and moulds for customized part as per the drawings or samples provided by the customers.

Pressure Die Casting Tools

Get Price Quote

Pressure Die Casting Tools, plastic die mould

Aluminium Die Casting

Get Price Quote

Aluminium Die Casting, SHEET METAL SPRING BALANCER, Recoiled Hose

Ci Casting

Get Price Quote

Alloy Cast Iron Casting, Iron Casting

embossing dies

Get Price Quote

embossing dies, Die Fixture Tools, Metal Pen Clips, Tool Cutting Dies

Pressure Die Casting

Get Price Quote

We are the leading service providers for Pressure Die Casting. Our Pressure Die Casting services are reliable and are extremely popular among clients. We offer our Pressure Die Casting services at the market leading prices. The services we offer are effective and are designed keeping the work requirements of the clients in mind. We have the advanced machines and tools to carry out superior quality Pressure Die Casting process. Our team is skilled and experienced in this area which enables us offer high standard Pressure Die Casting services. Description It involves a process of melting the metal and compelling them into steel diesAfter hardening, the metal takes the desired shapeThe movement of a plunger controls the processThe plunger reverses direction after the solidification time and ejects the part and gets ready for the successive cycle Types of Pressure Die Casting Hot chamber casting The plunger forces a preset quantity of molten metal into the die cavity. This process is used for zinc, copper, magnesium and lead which have low melting points.Cold chamber casting Molten metal is introduced into the injection cylinder and is forced into the cavity at high pressures. Aluminum and copper have high melting points and so are suitable for this process. Advantages Creates parts with no joints by eliminating other processes such as welding and fasteningIntegral fastening elements can be includedDimensional accuracyDoes not require more machine operationsReduced costCapable of producing a wide variety of complex 3D shapes Used for Machine components ToysEngine parts Industries Automobile IndustriesAerospaceMedical Nonferrous alloys that have low melting points are processed with this technique. Such as AluminumZincMagnesiumCopperLeadTinSilver

Die Casting

Get Price Quote

Die Casting, Machine Tool

pressure castings

Get Price Quote

pressure castings, Gravity Die Casting Components, Die Castings

Pressure Vessels

Get Price Quote

Centrifuges, Wastewater Treatment Plants, solar photovoltaic cells

Tundish Boards

Get Price Quote

silica board

Pressure Vessels

Get Price Quote

Pharmaceutical Machinery

Graving Die Cast

Get Price Quote

Graving Die Cast, Rubber Mould, Die Rotational Mould

Pressure Vessels

Get Price Quote

Heating Equipment, Ibr Steam Boilers

Pressure Vessels

Get Price Quote

Crystallizer, plant machinery equipment, Reactors

Die Casting

Get Price Quote

Die Casting, Dies