BOPP Adhesive Tape Coating Plant

Get Price Quote

Cement company paper bag shredder machine

300,000 - 500,000 Per Piece

1 Piece (MOQ)

Best Deals from Cement Plant Parts

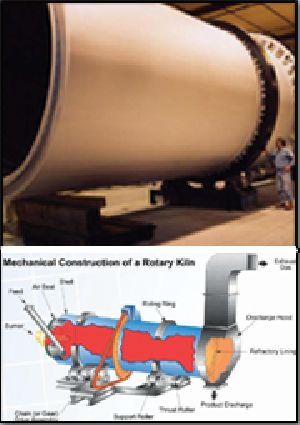

Rotary Kilns

Get Price Quote

Aswathi Industries Limited (AIL) has proven to be one of the leading manufacturers and suppliers of Rotary Kilns for numerous industries for decades now. AIL offers a wide range of kilns having superior quality, extensive workability, long service life and resistance against corrosion. AIL specializes in design and engineering of durable and cost effective kilns to give optimum performance suitable for various industrial applications. These machines are precisely manufactured and quality tested in compliance with the international standards of quality at our technologically advanced manufacturing units. Direct Fired Rotary Kilns are fuel fired, refractory lined Rotary Kilns.

Dry Mix Mortar Plant

Get Price Quote

To cater to the emerging demands of construction sector, we are able to bring forth high-tech Dry Mix Mortar Plant. These Dry Mix Mortar Plants are designed by our engineers for the fast and effectual mixing of mortar. Our Dry Mix Mortar Plant is assembled using high-end components that facilitate hassle free operation. Highlights : Effectual mixing of mortar Robust construction Easy to operate Saves labor cost

Cement Silo

Get Price Quote

To produce concrete, we use different types of equipment and cement silo is one of them. This machine is also known as a flash silo. This helps in storing cement in huge quantity. The main aim of using a cement silo is to reduce the storage cost by storing the purchased cement in bulk quantity. At Sabin Enterprises, Maharashtra, you will get the best cement silo that you can use in your construction site. In the concrete production process, our cement silo plays a very important role. How To Choose The Perfect Cement Silo? Several factors are responsible for choosing the right cement silo for your company. The first thing that you should check is the leading site design. This the right way to choose the right model of cement silo. Secondly, the power source and height restriction is important. And lastly, the thing that you should consider is shifting the silo from one place to another. Our company is the best cement silo manufacturer. Choose our highly durable cement silo machines and use it for different purposes.

MS Cement Silo

500,000 Per Piece

Rotary Kiln

Get Price Quote

The kiln is a cylindrical vessel, inclined slightly to the horizontal, which is rotated slowly about its axis. As the kiln rotates, material gradually moves down towards the lower end, and may undergo a certain amount of stirring and mixing.

Rotary Kilns

Get Price Quote

We pleased to get this opportunities to introduce our firm specialized for undertaking refractory Installation work. We involve in this field since long back time and executed several new projects as well as rebuild/ repairing work in India and abroad with excellent quality of work performance within a stipulated time frame. Our company is registered and developed with all infrastructures i.e. equipments, tools-tackles, organized workmen team. So, we are capable to undertake any quantum of related work in any industry and for your kind information, we have our own EPF code, ESIC code no, GST, PAN and manpower holding with valid passport. So, we can comply all statutory liabilities and fulfill all obligations. Assuring you that we shall always be at the best service in future and all your enquiries will receive our best attention, we request you for your kind consideration for us.

Adhesive Making Plant

6,500,000 Per Piece

Plaster of Paris plant

Get Price Quote

The natural gypsum powder includes anhydrous gypsum and CaS04.2H2O, if you want to commercialize the gypsum powder, you should adopt the CaS04.2H2O, after removing part of water by heating, it will become CaS04.12 H20. CaS04.12 H20 is the final product which you can use it to produce gypsum board other gypsum product. After calcining, CaSO4.12H2O is widely used in paper faced gypsum board and gypsum block and painting gypsum powder and model. Natural gypsum generally includes dehydrate gypsum and anhydrous gypsum. In order to get the valuable materials, generally, we get semi-hydrated gypsum through heating the dehydrate gypsum

Rotary Kilns

Get Price Quote

the leading manufacturers and suppliers of Rotary Kilns for numerous industries for decades now. AIL offers a wide range of kilns having superior quality, extensive workability, long service life and resistance against corrosion. AIL specializes in design and engineering of durable and cost effective kilns to give optimum performance suitable for various industrial applications. These machines are precisely manufactured and quality tested in compliance with the international standards of quality at our technologically advanced manufacturing units.

Hydraulic Cement Block Machine

Get Price Quote

We are counted amongst the prominent manufacturers, exporters and suppliers of the Hydraulic Cement Block Machine. Our Hydraulic Cement Block Machine is especially designed by our experts as per the needs of the customers. Features High strengthDurableCreates minimal noise Application Construction industry

Sturdy Design Dry Mix Mortar Mixing Plant

Get Price Quote

Cement Packing Machine

Get Price Quote

The company is a successful Manufacturer, Supplier and Exporter of Cement Packing Machine. Our machine is microcontroller based impeller type packing machine useful for packing any free flowing powder. The machine offered by us is extensively used for packing powder material such as cement, fly ash, bentonite, white cement, cement paints, pigments, dyes, chemicals, flours, soda ash, etc. Features : Micro Processor based stationary and rotary Electronic Packers. Fully automatic Filling & Weighing. Output of the machine is 15 to 18 tons/hour/spout. Digital weighing system with indicator. Latest technology and user friendly designs. Two stages filling of the material inside the bag ensures better accuracy in weighing. Uses pre stitched ale type bags. Hence, no stitching is required after the bags are filled. Same machine can be used for packing cement in jute, HDPE (woen), or paper bags (non-laminated). Aailable in 1 to 6 filling spouts in stationary model and 4 to 16 filling spouts in rotary model. Easy aailability of spares and after sales serice. Adantagesof the Machine : The cement is pushed by the Impeller & since air is required only to fluidize the cement inside the casing, ery less air enters into the cement resulting in low spillage. The Microprocessor based Control System ensures that no bags is filled with the minimum acceptable weight. In case the bag is filled with less than the acceptable weight, the Microprocessor does not allow the bag to be released & the system can be restarted automatically/manually to fill the balance cement in the bag. This way no bags will be packed with less weight. The filled bag remains hanging on the Nozzle until the Microprocessor ensures actual weight of the bag after the filling cycle is completed & the gate is closed. This way the operator can check the weight of each filled bag before it is ejected. Flow is controlled by a specially designed Slide gate which is operated by 3 position Pneumatic cylinder. Ring aeration proided on back of nozzle reduces nozzle clogging.

Bopp Self Adhesive Tape Plant

Get Price Quote

BOPP Self Adhesive Tape will stick to a vide variety of clean and dry surface with only minimum pressure applied. • It is ready to use and no activation with water, solvent or heat is required. BOPP tapes consist of relatively thin flexible tape coated with adhesive which is, permanently sticks at room temperature. The tape is manufactured with adhesive coating on one side.

Rotary Kiln

Get Price Quote

After giving tough competition to our contemporaries in Ahmedabad(India), we have now come forth to challenge the providers in other markets.We team makes sure that all the trade transactions are made keeping all the details of the clients confidential. Features: Durability Flawlessness Premium quality

Plaster of Paris plant

Get Price Quote

Cement Silo

1,000,000 Per unit

1 Unit (MOQ)

Cement Silo

Get Price Quote

Soil Cement Mixing Plant

Get Price Quote

Soil Cement Mixing Plant Soil Cement Mixing Plant, Stabilised Soil Cement Mixing Plant. asphalt mixing plant and portable asphalt mixing plant manufacturers premix feed mixing