Trunnion Mounted Ball Valves

BONETTI WVE valves comply with ISO, API, ASME, ASTM, B.S., DIN, etc., and particularly BS 5351, API 607, API 6D & API 6A. The whole range is “Fire-safe” tested and certified according to API 6FA, API 607 and B.S. 6755 Part II specifications. On request CE certification can be released. BONETTI WVE ball valve range includes both “floating” as “trunnion” mounted valves. Valves can be equipped with “soft” seats as well as with metal to metal seats. BONETTI WVE ball valves are designed to withstand high pressure and both high or low temperature (cryogenic application).

...more

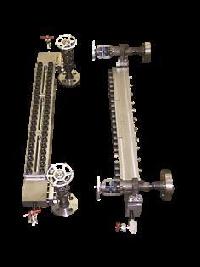

Transparent Glass Level Guages

Features: - fitted with two plate transparent glasses - fluid level is indicated as the result of the different transparency of the two media - “right-handed” or “left-handed” according to the position of the shut-off valve compared with the gauge body - the nominal passage diameter in the gauge is 10 mm.

...more

Testable Pneumatic Check Valves

Sizes - 4 to 34 (dn 100 to 850) for asme class 150, 330 - 4 to 20 or 16” (dn 100 to 500) for asme class 600 - 4 to 12 (dn 100 to 300) for asme class 1500 - 4 to 8 (dn 100 to 200) for asme class 2500 rating asme class 150, 300 bolted bonnet asme class 600 pressure seal bonnet and bolted bonnet asme class 1500 pressure seal bonnet asme class 2500 (pn 420) pressure seal bonnet.

...more

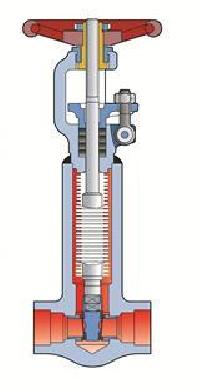

Stop Valves Bellow Sealed

Bonetti’s bellows seal valves are zero emission and maintenance free. The valves are particularly suitable for dangerous, inflammable, lethal and explosive media: an uninterrupted metallic barrier is positioned between the piping and the environment. Hence these valves are suitable for any fluid and are recommended when zero emission characteristics are required to protect the environment and the health of the workers from pollutive leaks, to prevent expensive wastes due to loss of energy and fluid, and to eliminate the not negligible cost of replacement of the packing.

...more

Spare Glasses For Level Gauges

Bonetti level gauges spare glasses – bont sight glasses for level gauges sizes: pn 6 to 420; ansi 150 to 4500 materials: carbon steel, stainless steel, hastelloy, monel, nickel, titanium, other special alloys, plastic materials types: tempered, toughened, hardened, prestressed, extra hard applications: - borosilicate glass is suitable for many application features: - have chemical and physical properties - chemical resistance due to heat treatment: hydrolytic resistance.

...more

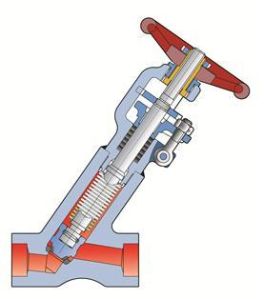

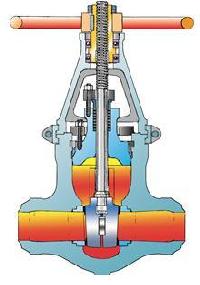

Piston Valve

Piston valves have been selected to meet the severe demands of a large number of requirements in fluid handling applications in the industrial sector. As such, they are used in process lines containing many different fluids such as steam, superheated water, thermal transfer fluids, ammonia, LPG, hydrocarbons, acids, alkaloids, etc. Their ability to provide perfect seat shut off and packing tightness, and their long term trouble-free operation, ensured by our patented reinforced seal rings, have served to greatly expand the number and types of applications where the BONETTI Piston Valves are used. This is particularly true of their use in the handling of harmful and flammable fluids where tight seat and packing shut off is essential.

...more

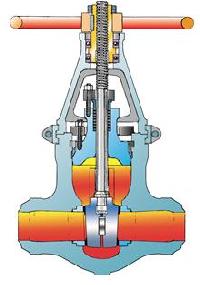

HP Globe Valves

Standards bonetti’s “cmi” valves have been designed, rated, manufactured and inspected, where applicable, in accordance with most widely used international standards, namely: - asme b16.34 "steel valves, flanged and butt welding ends" - asme b16.10 "face-to-face and end-to-end dimensions" - applicable sections of asme boiler and pressure vessel code, including nuclear section iii - mss sp 44 "steel pipe line flanges” - mss sp 61 "hydrostatic testing of steel valves” - api standard 598 "valve inspection and test” - asme b16.25 "butt welding ends" connections.

...more

HP Gate Valves

Standards bonetti’s cmi gate valves have been designed, rated, manufactured and inspected, where applicable, in accordance with the most used international standards, namely: - asme b16.34 -steel valves, flanged and butt-welding ends - asme b16.10 -face-to-face and end-to-end dimensions - applicable sections of asme boiler and pressure vessel code, including nuclear section iii. - mss sp 44 steel pipe line flanges - mss sp 61 hydrostatic testing of steel valves - api standard 598 - valve inspection and test - asme b16.25 - buttwelding ends - trd 110 (on request).

...more

high temperature ball valves

ASME B16-34, B16-5, B16-11, B16-25, MSS SP 72, BS 5351, DIN 3239 Standards. Size: Full Bore ½" to 2.½" - Reduced Bore ¾" to 3" Rating: PN 40 DIN 2401 - ASME300 full rated PN 100 DIN 2401 - ASME 600 full rated Temperature for continuous service: up to 550 °C - up to 1022 °F FIRE SAFE according: API 6FA Second Edition 15.02.94, API 607 Fourth Edition BS 6775 part 2 and Appendix A TA-Luft according: Technical Instruction on Air Quality Control Nr. 3.1.8.4 German I.Allgemeine VwV zum Bundes-Immissionsschutzgesetz (BlmSchG)

...more

High Pressure Bellow Seal Valves

Bonetti’s bellows seal valves are zero emission and maintenance free. The valves are particularly suitable for dangerous, inflammable, lethal and explosive media: an uninterrupted metallic barrier is positioned between the piping and the environment. Hence these valves are suitable for any fluid and are recommended when zero emission characteristics are required to protect the environment and the health of the workers from pollutive leaks, to prevent expensive wastes due to loss of energy and fluid, and to eliminate the not negligible cost of replacement of the packing.

...more

High Pressure Ball Valves

ASME B16-34, B16-5, B16-11, B16-25, MSS SP 72, BS 5351, DIN 3239 Standards. Size: Full Bore ½" to 2.½" - Reduced Bore ¾" to 3" Rating: PN 40 DIN 2401 - ASME300 full rated PN 100 DIN 2401 - ASME 600 full rated Temperature for continuous service: up to 550 °C - up to 1022 °F FIRE SAFE according: API 6FA Second Edition 15.02.94, API 607 Fourth Edition BS 6775 part 2 and Appendix A TA-Luft according: Technical Instruction on Air Quality Control Nr. 3.1.8.4 German I.Allgemeine VwV zum Bundes-Immissionsschutzgesetz (BlmSchG)

...more

Fully Welded Construction Ball Valves

Standard features - design, manufacturing and materials according to ped directive. - single piston effect, providing self-relieving of the body cavity. - product certificate atex. - api 6d certificate - monogram - fire-safe approved design - design to ansi b16.34 - blow-out proof stem - bi-directional - antistatic design - resilient sealing

...more

forged steel gate

STANDARD BONETTI’S forged steel valves are designed according to API 602. RATING BONETTI’s Forged Steel GGC valves are design in compliance with ASME B16.34 Pressure and Temperature rating. APPROVALS BONETTI® Forged Steel GGC valves are manufactured in accordance to ISO 9001:2008 and approved according - Pressure Equipment Directive 9723ES (“PED”) - Indian Boiler Regulations-1950 ACTUATED VALVES BONETTI® Valves can be equipped with pneumatic, hydraulic or electric actuator for remote controls.

...more

Forged Steel Floating Ball Valves

The Bonetti’s floating ball valves are equipped with an integral actuator mounting plate designed and manufactured according to ISO 5211 specification. This easily and uniformly enable mounting of actuator provided with ISO 5211 mounting flange. With ISO mounting flange no need to loosen body when fitting actuator. The three piece body construction enables user’s maintenance and replacement of internal parts of in-line valves. Quality Valves & Level Gauges

...more

Continuous Blowdown Valves

The continuous blowdown valves are needle valves designed for operation in open position. their function is mainly to control a continuous flow of steam andor water under high ap. For that reason the design and materials must be such as to minimise the effects of a fluid stream in condition of flashing or made of water containing sometime abrasive particles. The outlet of our valves is purposely venturi tube-shaped. the bonnetiess design enables easy dismantling, inspection and maintenance. the stem is rising, non-rotating. a local stroke indicator shows the position of the disk. The materials used for these valves are indicated on page 2 for the most requested material schedules, namely: material schedule 71, with carbon steel body; material schedule 22, with chromemolybdenum alloy steel body.

...more

cast steel gate

STANDARD API 600 ISO 10434 - Gate Valve—Flanged and Butt-welding Ends, Bolted Bonnet BS 1873 - Steel Globe valves. BS 1868 – Steel Check valves. ASME B16.34 – Flanged, Threaded, and Welding End ASME B16.10 – Face to face and end to end dimensions. API 598 – Valve inspection and testing ASME B16.25 – Butt welding ends ASME B16.5- Flanges and Flanged Fittings APPROVALS BONETTI® low pressure Gate Globe and Check valves are manufactured in accordance to ISO 9001:2008 and approved according - Pressure Equipment Directive 9723ES (“PED”) - Indian Boiler Regulations-1950 ACTUATED VALVES

...more

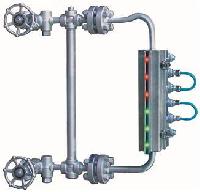

Bicolour Level Gauges

Features: - the two opposite glasses fitted are not parallel (the bicolour gauges has a trapezoidal body) - a red and a green screens are fitted - the portion of visible length occupied by steam is red - the portion of visible length occupied by water is green - “right-handed” or “left-handed” according to the position of the shut-off valve compared with the gauge body - the nominal passage diameter in the gauge is 10 mm.

...more

HP Check Valves

Standards bonetti’s cmi check valves have been designed, rated, manufactured and inspected, where applicable, in accordance with the most popular international standards, namely: - asme b16.34 - steel valves, flanged and butt-welding ends - asme b16.10 - face-to-face and end-to-end dimensions - applicable sections of asme boiler and pressure vessel code, including nuclear section iii. - mss sp 44 steel pipe line flanges - mss sp 61 hydrostatic testing of steel valves - api standard 598 - valve inspection and test - asme b16.25 - buttwelding ends - others (on request).

...more

Reflex Glass Level Gauges

Application: - can be used in most of application - offer great advantages such as low initial cost, low operating cost, easy level reading - cannot be used when the separation level between two liquids has to be read (interface) - cannot be used when besides the level indication, the observation of the liquid colour is required - cannot be used when the process fluid is high pressure water steam - cannot be used when the process fluid can corrode the glass features: - the liquid level is distinguished by the different brightness of the reflex glass in water or in steam space - “right-handed” or “left-handed” according to.

...more

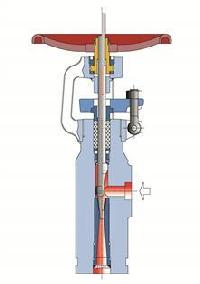

Automatic Bypass Valves

This two valve system has been designed to prevent risks in case of failure of high pressure preheaters. It consists of one 3 way valve and one 2 way valve having both an internal piston connected to the stem and sliding into a cylindrical chamber. In case of heater tube bundle failure, a level switch sensing the water level in the preheater shell will open the exhaust valves generating differential pressure between the two parts of the cylindrical chamber. This pressure difference actuates the stem movement, operating the valves and deviating the flow, therefore bypassing the preheater. Operating speed can be controlled by an external regulating valve. All this system does not need any external power (i.e. Electrical or pnaumatical) so giving best protection in case of accident. We produce this system according to rating asme 900, 1500, 2500 and special classes in size up to dn 18".

...moreBe first to Rate

Rate This