scraper chain conveyor

200,000 - 500,000 Per Piece

1 Piece (MOQ)

Bottle tilter conveyor

600,000 Per Set

Best Deals from Chain Conveyors

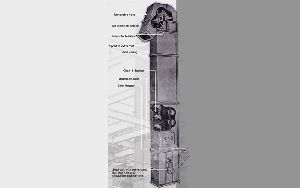

Redler Chain Conveyor

Get Price Quote

we are a distinguished manufacturer, supplier and exporter of redler chain conveyor in the global market. These redler chain conveyors can easily move vertically, horizontally, and around the beds providing great ease to the customers. It is ideal for transportation of goods in bulk, from one place to other economically. Some of the specifications of redler chain conveyor are listed below :salient features uniform and accurate feeding solid columns for material handling ensures no internal disturbances automatic feeding easy to discharge load at any opening

chain elevator

Get Price Quote

1 Pieces (MOQ)

Trimurti centrifugal discharge vertical elevators are used in lifting the material vertically. They are available in any height complete with top, bottom, and intermediate casing. The frame is made of Mild Steel sheet made rigid by angle iron, fitted with seamless pressed steel Buckets and Elevator Chains, Cast Iron sprocket wheels are mounted on a shaft supported by double row Self-aligning Ball Bearings. The take–up arrangement is at the bottom for easy erection and corrects tensioning of the chain. The buckets are spaced at a suitable distance. The top shaft is extended for drive purposes. Chain-Bucket elevators are available in the following sizes Chain No. - Bucket Size 57- 6″ x 4″ x 3.25″ 578 - 8″ x 4″ x 3.25″ The above Elevators can transport 1.25″ tons to 4 tons of material per hour depending upon the size of buckets, speed of the elevator, and the type of material being handled. Belt bucket elevators can also be supplied.

M S Slat Chain Conveyor

150,000 - 600,000 Per piece

1 piece (MOQ)

Chain Conveyor

Get Price Quote

With the help of our efficient workforce, we are able to offer our customers a comprehensive collection of Chain Conveyors. These conveyors are developed as per industry norms, using superior raw material, which is sourced from the reliable vendors of the market. In addition to this, our conveyors are widely appreciated by the clients due to their durability, easy operations, low maintenance, easy installation and robust construction features. Our range consists of the following types of chain conveyors : • Slat type chain conveyors & elevators for bagasse• Chain conveyors for metal scraps & metal chips• Pellet handling chain conveyors for automobile industry• Bags handling stacker conveyors for sugar godowns• Different type of chain conveyors for packing industries

Slat Chain Conveyor

40,000 Per unit

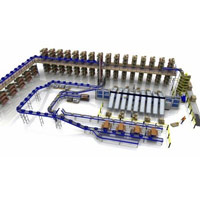

Slat Conveyor System

Get Price Quote

We Manufacture, Supply and Export an extensive range of Slat Conveyor Systems that is acclaimed due to its technology in the market. Designed using high-end technology, the Slat Conveyor System offered by us is known to improve the material handling capabilities and function smoothly even while handling high workload. Why Our Slat Conveyor System? Requires less lubricationLow on maintenanceHighly efficientRobust constructionAvailable in standard and customized models Finds Application In Packaging industryPharmaceutical industrySugar MillsFood processing industry

Wire Mesh Conveyor - 02

Get Price Quote

We are well reckoned as one of the overruling Wire Mesh Belt Conveyors Manufacturers based in India. Our Wire Mesh Conveyor is manufactured from the high quality raw materials as per the national and international quality standards. Wire Mesh Conveyor Belt provided by us is characterized by high performance, rugged construction and anti abrasive nature. Z-47 Articulated Wire Band Z-47 Type Band Are Manufactured Using Carbon Steel Of Stainless Steel or Stainless Steel Wire Coils Meshed Into One Another Lamination Of The Obtained Weave Gives A Perfectly Flat Surface Which Allows Free Air Circulation For Rapid Drying & Backing . Since The Coils Articulate Into One Another, Z-47 Band Have A Greater Longitudinal Flexibility To Enable The Band To Follow The Over Roller & Tensioner Surfaces. Z-47 Band Edges Have Been Carefully Designed In Order To Strengthen The Sides While The Band Keeps Entirely Its Flexibility Without Any Uneven Thickness. As Per The Requirement, The Z-47 Articulated Wire Band Are Made From 17 Gauge (1.40mm) & 18 Guage (1.20mm), 20 Gauge (0.90mm) Wire Of Carbon Steel & Stainless Steel 304.

Chain Conveyor

Get Price Quote

Chain Conveyor is used in horizontal bulk material conveying for abrasive and hot material which cannot be handled by Belt Conveyors.

CHAIN / SLAT CONVEYORS

Get Price Quote

With the help of our efficient workforce, we are able to offer our customers a comprehensive collection ofChain Conveyors. These conveyors are developed as per industry norms, using superior raw material, which is sourced from the reliable vendors of the market. In addition to this, our conveyors are widely appreciated by the clients due to their durability, easy operations, low maintenance, easy installation and robust construction features.• Slat Type Chain Conveyors & Elevators For Bagasse• Chain Conveyors For Metal Scraps & Metal Chips

Slat Conveyors for Structures

Get Price Quote

1 Piece(s) (MOQ)

Material Handling is the movement, storage, control and protection of materials, goods and products throughout the process of manufacturing and distribution. Material handling systems are a fundamental part of the manufacturing system since it interconnects the different processes.

Multi line slat conveyor

Get Price Quote

Multi line slat Conveyor Consist of Slats with Multiple lines parallel to each other for the common effect of greater width for transfer or diverter functions.

Magnetic Conveyor

Get Price Quote

We are offering magnetic conveyor please write to us for your specific need on biteral.

SS Slat Conveyors

Get Price Quote

Slat Conveyors are ideal for assembly line or production applications where a flat carrying surface is desired.

Dry and wet coconut scraper

35,000 Per Meter

1 piece (MOQ)

One and only one machine in which you can scrap dry as well as wet coconut simultaneously. Best for commercial grinding of dry and wet coconut which is used in many food processing industries like bakery, sweet making etc. Easy to use and easy to clean

Chain Driven Roller Conveyors

Get Price Quote

Each type of conveyor comes in five variations, to meet any conveyor requirement SHARP, an all round manufacturer of material handling systems, is actively developing material handling equipment and systems to attain these three targets. We are also ready to reliability and positively satisfy any customer requirement.

Slat Chain Conveyor Belt

2,000 Per Meter

Chain Conveyors

Get Price Quote

Conveying the material along the path of travel is easy with Techno Link. We are designing, manufacturing, supplying and installing Drag Chain Conveyors for tranporting the material along the path of travel. It generally have a low bed height and are open type. These conveyors are designed for horizontal, inclined and vertical transport of coal, wood, TDF, lime, sawdust, chips and other bulk goods. It is used for handling slightly sluggish, loose, lumpy hot material, abrasive andor corrosive materials. The conveyor comprises of flights that are fixed between two strands of chain and drags the material from feeding end to the discharge end in open or closed trough. Drag Chain Conveyors utilises a powered continuous chain arrangement, carrying a series of single pendants. Generally these conveyors are easy to install and have very minimum maintenance for the clients. These are available in different widths and lengths as per the site requirements. We manufacture these Chain Conveyors as per the defined industry standards and site requirements.

Chain Conveyor

Get Price Quote

Chain Conveyor is basically a convenient way for transporting bulk material from one location to another in horizontal, inclined and vertical position. In this, one or more chains act as the conveying element and it can convey material multi-dimensionally at a time. The conveyor adapts it arrangement to any local condition. Chain conveyors are exported / supplied in various types i.e. Apron,Slat, U, Drag and Redler chain types to convey material in horizontal inclined and vertical position. The Chain Type Conveyor is available in various sizes of width from 200 mm to 2000 mm width. Chains read in Double Strands generally. Conveyor is closed from all sides and “Drag Plate” is fixed in between two rows of chains runningparallel to each other. Chain conveyors generally have double or triple strands of chains running over fabricated frames. They are often used in conjunction with roller conveyors, handling cartons, bins, warehouses etc. A chain conveyor provides good positive drive and is an economical form of transportation of goods. A comprehensive range of low power consuming, sturdy chain conveyors, manufactured using quality raw material can also be offered as per customer’s specifications. Series of Chain Conveyors includes: Gravity Conveyor Fine Conveyer Uni-Con Ois Conveyor Portable Conveyor Industrial roller chains used for carrying the materialdepending upon geometry of material to be carried, available space and ambient conditions, it can be constructed in ½”, 5/8”, ¾” , 1”, 1.5” pitch with simplex, duplex and triplex chain. Being standard available chains are used, these conveyors are easy to manufacture as well as easy for maintenance. These conveyors are generally used for carrying materials like steel billets cold or hot upto 1200 deg C, forged / cast items etc. These conveyors are used to convey forged components from forging press to trimming press. Width of conveyor depends upon dimensions of component to be handled. Heavy to Medium sized components can be handled on these types of conveyors. These conveyors are also used to handle flash from trimming press. These are high speed conveyors.