PVDF (Injection-Molded) And PTFE Lined Back Pull Out Pumps

Get Price Quote

We LEAKLESS (INDIA) ENGINEERING are leading manufacturer and exporter Of LCP Series PVDF (Injection-Molded) And PTFE Lined Back Pull Out Pumps , specially designed for highly corrosive liquids and high temperature applications. These types of pumps deliver outstanding performance with economical prices .The range being easy in use and demands minimum maintenance. Pumps offer thick injection molded casing with C.I Or S.S casing liner insert for strength of casing with easy replaceable method. Semi open (Injection-Molded) Impeller with metal insert. Excellent mechanical properties over a wide range of temperatures up to 150º C. Material Of Construction POLYVINYLIDENE FLUORIDE (PVDF) POLYTETRAFLUOROETHYLENE (PTFE) Applications And Industries Served CHEMICAL PROCESS UPTO 150OC ORGANIC/IN ORGANIC CHEMICAL HIGHLY CORROSIVE ACID TRANSFER AIR CONDITIONING EFFLUENT ELECTRO PLATING HIGHLY CORROSIVE ACID TRANSFER DYES AND PIGMENTS SCRUBBER UNIT WATER TREATMENT SOLVENTS UNLOADING TRANSFER OF LIQUID

Life Boat Diaphragm Manual Hand Pump / Hand Bilge Pump 720GPH Plastic

1,900 - 1,901 Per Piece

1 Piece (MOQ)

High Quality nylon self priming hand pump with Fixed Plastic Handle. 25.4mm or 38.1mm hose. Draws 15 gallons per minute Application: Suitable for pumping bilge water, saltwater or diesel transfer. Hand pumps compact design easily installed in tight bilge spaces.Features: 1. Diaphragm hand pump with Fixed Plastic handle2. Self-priming3. Capacity: 720GPH (2724LPH)4. Hose Dia.: Inlet OD. 1"(25.4mm)/ 1-1/2” (38.1mm) outlet OD. 1” (25.4mm) / 1- 1/2"x38.1mm)5. Max suction lift: 3m (10ft)6. Max discharge head: 4m (3.5ft)7. Easy to remove clamp ring for maintenance/head rotation

Best Deals from Chemical Pumps

GilAir Plus Air Sampling Pump

Get Price Quote

The most Advance Air Sampling Pump in the world! Easily Monitor Activity with Your Mobile Device! Quickly set up a mobile device for remote (via Bluetooth) internal motion monitoring, logging that provides improved sample integrity, in-process sample auditing, snapshots, and automatic reports of current conditions. Complete instructions are included with the GilAir® Plus. QuadMode Air Sampling Technology Wide, dynamic flow range provides high-flow constant pressure and constant flow, and low-flow constant pressure and constant flow without external adapters. SmartCal Automatic Calibration The SmartCal feature uses the dock as a communication link between appropriate calibration devices and the GilAir® Plus. It automates calibration and records pre and post sample calibrations in the pump's datalog. Temperature & Pressure Compensation The GilAir® Plus pump operates in selectable ambient or standard mode correcting for temperature and barometric pressure when equipped with STP option and provides automatic flow correction option for barometric pressure changes. Features Quad Mode Air Sampling Technology Smartcal Calibration Motion Detection & Bluetooth Temperature & Pressure Compensation Superior Design & Comfort Real-Time Clock With Data-Logging Flow Rate Constant flow 20 - 5,000 cc/min. without external adaptors Constant pressure 1 - 5,000 cc/min without external adaptors Certifications US/Canada NRTL (FM) Class I, Div 1 Groups A, B, C, D, E, F, and G; Class II, Div 1 Zone 0; Class III, T4 ATEX/IECEx II 1 G Ex ia IIC T4

Chemical Dosing System

4,900 - 4,950 Per piece

1 Piece (MOQ)

The chemical dosing process treats wastewater with high levels of chemicals dissolved into it like aluminum, iron etc. A dosing system is designed to release chemicals at a certain pressure and speed into the water, depending on how much of chemicals are dissolved in the wastewater coming through the inlet. It is part of a water treatment plant so water that comes into the inlet goes through various filters of this system. Each filter will reduce debris till the water that is flowing goes to the dosing point. Now chemicals from the dosing tank are released into the water to treat it so that any chemical dissolved into it are removed.The treated water is sent to a calibration point where its standards are assessed. If so, it is then sent to another chemical cleanup process so that it is safe for consumption. In case, at the calibration point the water is not up to the standard mark, it is sent back to the dosing point so that it is once again treated with chemicals. Key areas of application for Aqua Systems Technology dosing system are in the treatment systems for waste water, raw water, cooling water, boiler feed, ultra filtration and reverse osmosis. It is designed to be rugged and can work efficiently even if the environment condition can cause corrosion or other problems to occur.A team of qualified and experienced TECHNICIAN is always on it’s toes to provide any technical services to the customers round the clock. This ensures the utmost satisfaction of each customer, therefore an unbeaten faith of their in AST. A vision to make water treatment as the most sophisticated, scientific and competitive business, AST is thriving to excel. With matchless quality of products, committed delivery schedule, prompt services and customer friendly attitude, AST has achieved the exponential growth in short span of time. Pursuing highest standards and passing through stringent stage wise quality checks; AST produces a product that can optimize customer’s production. Products of high quality standards.Aqua Systems Technology is one of the best Dosing System manufacturer, Dosing System exporter, Dosing System supplier in mumbai India. We are provide this Dosing System product in all over countries. If you have this Dosing System product please visit here or quote NowWe are one of the leading manufacturers of high-quality Dosing System. Dosing pumps are manufactured in compliance with industrial quality standards. They can operate at speeds selected by the operator while continuous duty pumps maintain performance specifications at 100% duty cycle. Self-priming pumps are designed to draw fluid into the inlet without external assistance. Usually made from plastic, thermoplastic etc., dosing pumps are designed to move materials, acids, chemicals, coolants, hazardous fluid materials, lubricants etc. We supply them to clients at economical costs.Dosing pumps are available with many features and can move media with adjustable speed pumps can operate at speeds selected by an operator while continuous duty pumps maintain performance specifications at 100% duty cycle. Self-priming pumps are designed to draw fluid into the inlet without external assistance.Low-volume pumps with controllable discharge rates that are used to inject additives or difficult-to-mix fluids into mixing, pumping, or batch/tank systems. Dosing pumps are usually made from plastic, thermoplastic.Dosing pumps are designed to move materials, acids, chemicals, coolants, hazardous fluid materials, lubricants.

CZ Series Magnetic Drive Sealless Pump

Get Price Quote

TID 25 S Diaphragm Vacuum Pump & Compressor

Get Price Quote

1 Piece (MOQ)

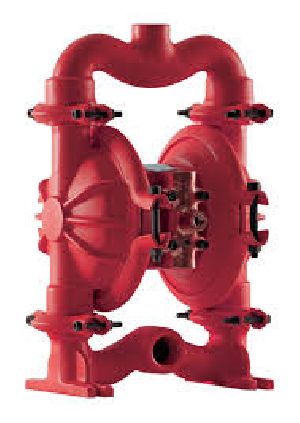

Air Operated Diaphragm Pump

Get Price Quote

Air operated diaphragm pumps are reciprocating pumps where the working elements are flexible diaphragms. The drive is by means of compressed air acting directly upon the diaphragm. Another possibility is hydraulically drive instead of compressed air. At least two valves, one on the discharge and one on the suction side, are necessary. Several types of valves are used. The most popular valves are flap, cylindrical and ball valves.Air-operated double diaphragm pump is a self promised pump to work hard against huge number of Liquids and atmosphere , donate driver seat to user.

Polypropylene BSP Diaphragm Pump

Get Price Quote

Specifications Max Flow Rate586Lpm (155gpm)Port SizeInlet : 50.80mm (2" BSP)Discharge : 50.80mm (2" BSP)Air Inlet : 12.70mm (12" BSP)Air Exhaust : 19.05mm (34" BSP)Suction LiftDry : 4.57m (15')Wet : 7.62m (25')TeflonDry : 3.05m (10')Wet : 6.09m (20')Max Particle Size (Dia)6.35mm (0.250")

Air Operated Double Diaphragm Pump

Get Price Quote

We offer superlative quality Air Operated Double Diaphragm Pump that is highly efficient. The Air Operated Double Diaphragm Pump is manufactured using high grade raw materials. We are regarded as one of the principal Air Operated Double Diaphragm Pump Manufacturers and Suppliers in India. It can be availed at highly affordable rates. Features : Self PrimingCorrosive and Slurries can be easily managedVariable speedProcess fluid must be compatible with material of constructionTeryair diaphragm pumps can be stopped by simply switching off the discharge valveEasy operation and maintenance Uses : Widely used to pump liquid with solid particles and high viscosity liquidThey can be used in positive and negative suction situations

HIGH PRESSURE AIR-OPERATED DIAPHRAGM

Get Price Quote

Husky 1050HP High Pressure Air-Operated Diaphragm Pump 1 inch Air-Operated Triple Diaphragm PumpThe Husky 1050HP has a 1 inch (25.4mm) connection and is available in aluminum and stainless steel. Choose between low pressure and high pressure operating modes with Graco’s low-high pressure mode valve.The Husky 1050HP air-operated diaphragm pump is the first pump on the market that allows users to choose between low pressure and high pressure operating modes with Graco’s low-high pressure mode valve. High pressure operation isn’t always required, so switch to the low pressure mode to reduce air consumption up to 50%. These features combined with the quality and reliability of our standard Husky diaphragm pump design; make this one of the most unique high pressure diaphragm pumps on the market.Benefits of the Husky 1050HP Double Diaphragm PumpIncreased fluid pressure without sacrificing flowLow-high pressure mode valve lets you operate the pump as a standard AODD or a high pressure AODDReduce air consumption up to 50% with the low pressure modeSame repair parts as the Husky 1050 diaphragm pumpOverviewMaximum fluid flow- 50 gpm (189 lpm)Maximum Fluid Discharge- 125 psi (17.2 bars, 1.72 MPa)Maximum size pumpable solids- 1/8 in (3.2 mm)Fluid displacement per cycle- 0.2 g (0.76 liters)Features:Increased fluid pressure without sacrificing flow Low-high pressure mode valve lets you operate the pump as a standard AODD or a high pressure AODDReduce air consumption up to 50% with the low pressure mode Same repair parts as our Husky 1050 air-operated double diaphragm pump reduces inventory levelsApplication areas: Filter press, ceramic, high head pressure or long distanceMaterial:AntifreezeGelcoatsAsphaltsPolyurethaneWindshield Washer FluidDiesel Exhaust Fluid (DEF)DetergentsPolymersFibersAlkydsResinMotor OilGear OilUsed OilHydraulic FluidAutomatic Transmission FluidCutting OilOilWaterWater - Wastewater TreatmentWater - Wastewater TransferWater - Freshwater TreatmentAutomotive UndercoatingApplications:Chemical TransferHigh-Viscosity Material TransferOil TransferBulk Supply SystemMedium-Viscosity Material TransferLow-Viscosity Material TransferIndustries:Paint KitchenMining Equipment - ManufacturingMining - Wastewater TransferMining Equipment - MaintenanceUpstream: Drilling and CompletionsPrinting and Publishing - Ink TransferWater - Wastewater TreatmentWater - Wastewater TransferWater - Freshwater TreatmentInk Transfer

Magnetically Driven Pumps

Get Price Quote

Pilot plants, Galvanizing, Anodizing, Plating Plants, Water treatment plants. Coolant pumping for leser systems & and machine tools. Etching machines,Metal finishing machines, Gas analysers, Spark errosion machines. X-ray photo processors, Color photo processors, Ultra sonic cleaners, Medical equipments. Solar heating systems ,I.C. photo engraving machines,Display devices,TV tube processing. Dairies, Soft drinks Bevarages, Pure water plant, Domestic Aquariem. General laboratories, Silver recovery systems, Water processors, ice makers.

Chemical Process Pump

Get Price Quote

These are Horizontal Centrifugal Back Pull-Out Designs as per ISO, DIN and API Standards. To complete the range of Metallic Pumps Sando is also manufacturing Vertical Submersible Pumps, Multi Stage Boiler feed water pumps. So far in India there is monopoly of few Multi National Companies offering high temperature Thermic fluid pumps which were fitted with Metal Bellow Seals which is prone to frequent failures.

pvdf chemical process pump

5,000 Per Piece

chemical pump parts

Get Price Quote

Chemical pump parts like casing, impellar and seals are manufactured from acid resistant carbon material with better machanical properties. Critically designed for optimum performance output and pressure.

Centrifugal Chemical Pump

Get Price Quote

We offer pumps for various applications such as chemical process, water light chemical duties, high flow – low head duties and dewatering, etc. * capacities upto 2000 m3hr and heads upto 250 m * temperatures upto 250⁰ c * choice of material of construction as per process requirement. * impellers designed to handle high quantum of solid content * sealing choice - packing, mechanical seals * components for pumps can be developed as per samples or drawings.

Chemical Process Pump

50,000 Per Piece

Liquid Ring Vacuum Pump

Get Price Quote

We offer liquid ring vacuum pump.

Air Operated Diaphragm Pump

Get Price Quote

Diaphragm Pump

Get Price Quote

mechanical pump

Get Price Quote

Details : Mechanical pumps serve in a wide range of applications such as pumping water from wells, aquarium filtering, pond filtering and aeration, in the car industry for water-cooling and fuel injection, in the energy industry for pumping oil and natural gas or for operating cooling towers. In the medical industry, pumps are used for biochemical processes in developing and manufacturing medicine, and as artificial replacements for body parts, in particular the artificial heart and penile prosthesis.

Diaphragm Type Metering Pump

Get Price Quote

1 Piece (MOQ)

JAKIM PUMPS Manufacturers of Hydraulically Operated Diaphragm Type Metering / Dosing pump for suitable service conditions involving hazardous toxic, radioactive or poisonous liquid where product leakage is not at all permitted. The Diaphragm is hydraulically actuated and has a long life as it is always in hydraulic balance, with the liquids being pumped on one side and actuating fluid on the opposite side. Its function is basically that of a partition. The diaphragm material is usually Teflon. The system is safety guarded by a in built Relief Vacuum Combancity Valve on the hydraulic side. For very severe duty conditions or when handling slurry or hot liquids, double diaphragm and remote heads can be provided.The Range includes high precision positive displacement pump conforming to API 675. Typical applications for our pumps are useful for accurate dosing and mixing of acids, alcoholics, slurries, viscous liquids etc. Our range covers everything from the single pump to a completed automated Metering dosing system and comprises of plunger and diaphragm pump with metering range from various capacity and pressure from 2 – 15000 LPH. pump can be offered in Simplex, Duplex, Triplex and Multiple Heads, handling for different chemicals with a common Motor. Each head would have independent connection and capacity of each head can be also independently adjustable.The pump discharge is variable while pump is running or at rest from Zero (0%) to full stroke (100%) by means of a precision machined Crank equipped with a stroke length adjustment mechanism. The Stroke of the pump controlled either Manually Wetted parts can be offered in S.S. 316 or 304, Carbon Steel, P.P. / Teflon / PVDF, Alloy 20, Hastalloy B or C. etc.Double Diaphragm Pump : It has a Diaphragm Rupture Indicator, which indicates if the Diaphragm gets damagedApplicationsDiaphragm Type Pumps are used in Chemicals Plant, Fertilizer Plant, Water Treatment Plant, Soap Plant, Paper Industries, Pharmaceuticals Industries, Thermal Power Projects, and Plastic Industries.

Chemical Process Pump

10,000 Per Piece

1 Piece(s) (MOQ)

PVDF Lined Chemical Process Pumps

25,000 Per Piece

Magnetic Drive Pump

200,000 - 5,000,000 Per Piece

1 Piece(s) (MOQ)

Centrifugal Chemical Pump

75,000 - 1,000,000 Per SET

1 SET (MOQ)

aodd pump

Get Price Quote

Chemical Process Pump

15,000 - 80,000 Per piece

1 P (MOQ)

Centrifugal Slurry & Chemical Pump

Get Price Quote

We are into marketing for one of the most genuine well renowned chemical slurry pumps & valve manufacturers which had been approved from llyods & irs & been regularly used by some very renowned companies specially government concers, following are some of the products which are specelized in. They have been regularly manufacturing materials like cd4mcu, ub 6, hv 9a, alloy 20, ca 6nm, cn 7m, din 4136, cf 3, cf 3m, cf 8, ca 15,din 1.4136, cf 8m, ni-resist, ni-hard, various grades of high alloy steels and any other special graded materials.facilities are available for ultrasonic and radiography tests

Chemical Transfer Pumps

Get Price Quote

We are a distinguished Manufacturer, Exporter and Supplier of Chemical Transfer Pumps from India. Expensively used for lubricating purposes, our Chemical Transfer Pumps are fabricated in a wide assortment of different specifications. They are very easy to use and extremely safe for installation in areas with high temperatures. Our Chemical Transfer Pumps is widely appreciated for efficiently transferring fluid from one container to another in a single stroke with double check valve.

Liquid Ring Vacuum Pump

Get Price Quote

We work with an aim of fulfilling variegated requirements of the clients. And, for this, we have developed a large facility wherein we keep our products. Buyers across Bhiwandi(India) and other markets can contact us for purchasing our product all year round. Salient Features: No Lubrication required Noiseless performance Absolutely Portable Totally Oil-free construction Practically maintenance free Built-in micro suction filter Special diaphragms available (Teflon / vi-ton etc.) Extra large bearings for trouble - free and smooth running Pump available with flameproof motor Pump available with chemical resistive parts (PP / PVC / Teflon / SS contact parts) Pump available for gas charging in Air conditioners Motors available in 110 V AC also Ideally suited for original equipment manufacturers