spray balls

500 - 2,500 Per pc

Technical Info 1. Connections: Plain End Pipe & Threaded Nipple for Rotary Type Spray Ball 2. Maximum Tested Pressure: 10 BAR 3. Minimum Working Pressure:-1BAR 4. Maximum Temp-95°C 5. Minimum Temp: -20°C 6. Material ( MOC ) - AISI 304/316/304L/316L Rotary Type Spray Ball Surface Treatment Mirror Polish Grade SS 304 Material Stainless Steel Temperature 0 to 140 Degree Celsius Size 2 inch to 4 inch Application Stainless Steel Spray Ball is used in Dairy Pharma & Beverage & Pharma Industries in CIP or Cleaning Systems. Sailent Features: 1. Precise Holes for optimum flow of liquid stream. 2. 360 Hole Slots for unidirectional Cleaning 3. Rotary Spray Ball is provided with Industrial Grade leak proof Bearing ensuring smooth Rotation. 4. The rotary Spray Ball is provided with threading at bottom for installation

spray ball

Get Price Quote

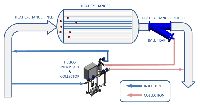

Spray Ball as they are known, literally, are one of the main components for cleaning tanks and vessels. We supply a variety of sizes, flow rates and configurations for a broad scope of cleaning jobs. Spray Ball are designed as static cleaners for flush cleaning with a high flow rate, thus providing powerful flushing at a relatively low pressure.

Best Deals from Cleaning Tool

Stainless Steel CIP Rotating Spray Ball

2,500 - 4,500 Per Piece

spray ball

Get Price Quote

spray ball, Stainless Steel Pipe, Aluminum Bronze Wire

SS Fix Spray Ball

950 Per Piece

10 Piece (MOQ)

spray balls

Get Price Quote

spray balls, stainless steel pressure tube, vent filters, Storage Vessels

spray balls

Get Price Quote

At Ambuja Tube Fitting we specialize in Mfg of various types of spray balls which are used as the most important and lethal tank cleaning systems by use of spray balls. Various models are available as per the degree of cleaning of tanks. We have taken hygiene to another level by easy and cost effective cleaning systems for tanks and equipments. Different models are available and shall be quoted on request. 180° Rotataing Spray Pattern - Stationary Spray Balls. AMBUJA make spray balls operates at lower pressure as at high pressure due to impact the spray can bounce making the use of spray balls non-productive. So Ideally it is advised to set the flow of water low so that the liquid will flow through the walls of tanks and clean the tank walls properly. To have proper effect of spray balls selection of right size and design is must.

cleaning sponge balls

Get Price Quote

Cleaning sponge balls, The Helios cycle is fully automatic and controlled by a programmable controller, as described below: Between cycles, the sponge balls are stored in the Collector and all valves are closed. At programmed intervals, the Controller commands the injection valves to open and pump to start, and the balls are injected into the heat exchanger inlet line.

Sanitary Cleaning Ball

Get Price Quote

Sanitary Cleaning Ball, Flanges, Butt-weld Pipe Fitting, Forged Fitting

spray ball

Get Price Quote

spray ball, Tube Expanders, Micro Filter Valve, Three Way Plug Valve

Under Sofa And Wardrobe Cleaning Tool

Get Price Quote

Under Sofa And Wardrobe Cleaning Tool, Pani Puri Plate, PVC Bedroom Wardrobe

Spray Cleaning Ball

Get Price Quote

Spray Cleaning Ball, Buttweld Nipple, Stainless Steel Scrap, S. S. Ring