Electrophoretic Coating Machine

Get Price Quote

1 Piece (MOQ)

The E-Coating process is a mixture of Plating process and Painting, where a DC voltage is passed through thework piece while immersed in a water based solution with a paint emulsion. The process results in the paintto adhere to the surface of the piece and form a layer. Moreover, creating attractive designs, E-Coating processes is used for getting Corrosion protection, Smooth and Lasting Finish. A Source of DC Voltage is a primary requirement for E-Coating process.That is where the role of E-Coating Plant comes in. E-Coating plant has great advantage over a simple voltage source since it has provisions to adjust voltage to required values.Temperature and Timer Control and in built Magnetic Spinner for glass beakers, making it perfect assistance inE-Coating process. Features :- Capacity : 2 Litres Equipped with Pyrex 2 Litre Glass beakers Heater : 300W Voltage adjustment through digital display and Stirrer to stir the solution ATP Anodes for Coating process Terminals provided with easy access

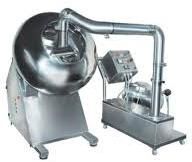

Auto Coater

Get Price Quote

Auto Coater has been designed to carry out most perfect and uniform coating with the minimum intervention of the operator. Auto Coater is designed as a free standing, totally enclosed unit, with inbuilt muti nozzle CIP system. The machine interiors are accessible through leak proof doors provided on rear, left and right sides. The unique VFD controlled perforated coating pan design utilizes a totally enclosed, highly efficient air flow system for maximum drying uniformity and minimum process time. Process air flows through the inlet duct and is directed down to the product bed. The air exits under negative pressure through the exhaust plenum located under the tablet bed. Fully automated rotary valves on inlet and outlet ducts located in the technical area control the quantum of inlet and outlet air as per batch size. Matching solution pump and spray guns optimize the coating process. Highly sophisticated, accurate and precise positive displacement self priming Peristaltic pump from Watson-Marlow of UK ensures the process stability and quality of the end product. All SS spray guns are choke-less in operation with automatic nozzle cleaning system. Their adjustable spray pattern and automatic controls make them suitable for the application of aqueous, organic, solvent based film coating and sugar solution coating. Our automated PLC / LCD based process control system with necessary hardware and software is designed to meet stringent requirement of process. The control parameters include system monitoring, control, feedback and data acquisition and processing. It Provides total security and can easily add or delete product recipe with proper password access. We tailor the operator interface graphics to customer’s requirement Spraying The ultimate in technology Spray Gun from spraying system USA, compliment the WATSON - MARLON Pump to give you the best of coating. Mounted on a sturdy manifold. They can be adjusted for spray quality and angle thus adapting the optimized spray area. No of Guns vary as per the size of the Autocoater. The manifold can be slid out for easy & complete washing. Control System for Manual and Fully Automated Operation : Our automated PLC / LCD based process control system with necessary hardware and software is designed to meet requirement of process. The control parameters include system monitoring, control, feedback and data acquisition and processing. It Provides total security and can easily add or delete product recipe with proper password access. We tailor the operator interface graphics to customer’s requirement.

Best Deals from Coating Machine

wire coating machine

1,500,000 Per Piece

Color coating line for home appliance

Get Price Quote

Adopt the international advanced three- coating -three- drying process, together with laminating, printing, which make the product has a beautiful appearance and excellent processing performance, corrosion resistance, resistant to scratch. Various surface impression and together with fancy design and glittery pattern cause this product have been widely applied to home appliance of refrigeratory, washing machine, etc.

VMCH COATING MACHNES

Get Price Quote

We are the popular manufacturer of VMCH Coating Machine. VMCH coating is done on Aluminium Foil. Colouring or Lacquering is of Aluminium, Metallized Film. VMCH Coating Machine from WebFlex Machines are popular in India & exported worldwide. Gamut of experience of our professional R & D staff has helped us to develop super quality VMCH Coating Machine. As is our forte we sell customized machine to our customers and these coating machines are popular for easy installation, smooth operation and easy maintenance. VMCH coating machine manufactured by us have multiple segments of industry for VMCH coating.

Hot Melt Adhesive Coating Machine

Get Price Quote

We manufacture Hot Melt Lamination Machine from best metal and alloy and this Laminating Machine is used for hot melt adhesive coating on various films. Features of Hot Melt Lamination Machine manufactured by Webflex Machines: Designed Hot Melt Coater & laminator of specially hot melt adhesives on flexible subtracts films. This Laminating Machine is compact, sturdy, has modular construction with integrated unwind & rewind units, coating lamination, controls etc. grouped for ease of operation. Unwind units are equipped with mechanical features for EPC & tension.

Pipe Coating Equipment

Get Price Quote

We offer powder spay booth with recovery system for pipe coating application. it is Easy to use and set up, this model is suited for small panel coating as well as small production runs.

tablet coating system

Get Price Quote

Coating Pan

140,000 - 145,000 Per Piece

Warp Around Hot melt labeling Machine

Get Price Quote

The Wrap around Hotmelt labeling machine is a high speed system ideal for round bottles. It is matched with R.F.C machine and the conveyor connecting both is synchronized to ensure smooth flow of bottles. A stainless steel star wheel or feed worm in case of high speed machines will take the bottle and place in front of the label application drum. The label is delivered by the sensor controls whose response time and control speed frequency of the electronic print mark registration system is very fast, and it works 20 times faster than any other Indian Hotmelt label applicator. The bottle is rolled over the label and on completion of label application, bottle will be discharged on the out feed conveyor. The synchronizing/correction speed is 350 MHZ and response time is 120 micro-seconds. For lower capacity machines to save cost we have developed our own Hotmelt unit, but for higher speed machines we use a Nordson, (U.S.A) system. All electronics used in our system are from leading suppliers such as Siemens, LG, Danfoss who have worldwide service support. The electronic registration system is servo controlled and the fly cutter is synchronized to it to ensure that label is cut with ±1 mm of the print mark. The label cutter is PLC controlled with a hardened tool steel blade. There is an alarm when the label reel starts to run low. If there is no bottle on conveyor, the label will not be delivered to the drum and if there is no label on the drum no adhesive is applied

spray coating machine

Get Price Quote

This is conventional and complete system to connect any Coating pan and most suitable for the rapid and uniform coating of Tablets, Granules & Pallets. The system consists of a stainless steel 316 quality pressure vessel provided with S .S. jacket with electric heaters and thermostat control and provided with safety valve, pneumatic oscilating type stirrer fitted on top of the vessel.

Hot melt coating machine

Get Price Quote

Hot Melt Coating MachineEquipped with a hot melt pre-melting and recirculation tanks.A rotogravure coating trolley is standard and a semi-flexo trolley is optional.This machine is suitable for producing soap wrappers (full and registered coating), chewing gum wrappers, bread wrappers,etc.

tablet coating system

Get Price Quote

we have manufactured Tablet Coating System that is used in various pharmaceutical industries. Automatic Tablet Coating System offered by us is fabricated using latest technological procedures. Designed for the purpose of coating granules, tablets and pallets, our Perforated Tablet Coating System is known for its high-precision and performance. In addition to this, we ensure availability of Perforated Tablet Coating System in different specifications and grades suiting to the preferences of clients. We are counted as one of the major Perforated Tablet Coating System Manufacturers from India.

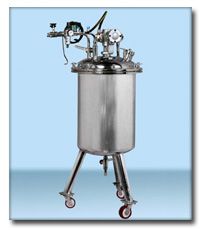

pharmaceutical coating machine

Get Price Quote

This is conventional and complete system to connect any Coating pan and most suitable for the rapid and uniform coating of Tablets, Granules & Pallets. CAPACITY AVAILABLE : 10 25 50 100 150 Ltrs. TECHNICAL SPECIFICATION : The system consists of a stainless steel 316 quality pressure vessel provided with S .S. jacket with electric heaters and thermostat control and provided with safety valve, pneumatic oscilating type stirrer fitted on top of the vessel. System available with plain vessel for Film Coating & Jacketed vessel for sugar coating.

pvd coating machine

Get Price Quote

Physical vapor deposition (PVD) is a variety of vacuum deposition and is a general term used to describe any of a variety of methods to deposit thin films by the condensation of a vaporized form of the material onto various surfaces. The coating method involves purely physical processes such as high temperature vacuum evaporation or plasma sputter bombardment rather than involving a chemical reaction at the surface to be coated as in chemical vapor deposition. Physical Vapor Deposition (PVD) is an environmentally friendly vacuum coating process that provides brilliant and durable decorative finishes on household appliances, stainless steel sheets, door hardware, jewellery, electronic components, automotive trim and marine fittings.

tablet coating machines

Get Price Quote

Pioneers in the industry, we offer Tablet Coating Machines such as Coating Machine for Tablets and Tablet Coating Machine from India. We hold expertise in offering high quality Tablet Coating Machines (GMP Model SMS 09) to our esteemed customers. The product, offered by us, is precisely engineered from high quality metals and alloys. Suitable for sugar or film coating of tablets or granules & colouring of tablets.Contact parts S.S. 316 and non contact parts S.S. 304. Ploshing can be interchanged with coating pan and can be supplied with hot air blower. Optional spray coating system. is also available

Hot Melt Labelling Machine

Get Price Quote

Fully automatic linear operation . Height adjustments to suit various bottle sizes. Automatic BOPP (Hot Melt) labelling Machine,Imported gluing unit sprays minimal quantity of hot melt adhesive. Automatic BOPP (Hot Melt) labelling Machine No cleaning of the nozzle or glue unit, before production. Automatic BOPP (Hot Melt) labelling Machine Minimal change-over time, to shift from one size to an another size.

Auto Coater

Get Price Quote

Automatic Film Applicator

1,250,000 Per Piece

Coating Pan

Get Price Quote

Used for coating of tablets/ granules. The pan is mounted in inclined position for effective coating. Unit is provided with suitable hot air blower to get desired temperature which can be controlled by thermostat. Used in pharmaceuticals bulk, drug and chemicals, foods Industries.Available Sizes :- 12” TO 72” M.O :- M.S, S.S.304, S.S.316, S.S.316 L