Hot Melt Labelling Machine

Get Price Quote

Fully automatic linear operation . Height adjustments to suit various bottle sizes. Automatic BOPP (Hot Melt) labelling Machine,Imported gluing unit sprays minimal quantity of hot melt adhesive. Automatic BOPP (Hot Melt) labelling Machine No cleaning of the nozzle or glue unit, before production. Automatic BOPP (Hot Melt) labelling Machine Minimal change-over time, to shift from one size to an another size.

Coating Pan

Get Price Quote

Best Deals from Coating Machine

spray coating machine

Get Price Quote

Spray coating machine many solid pharmaceutical dosage mediums are produced with coatings, either on the external surface of tablets, or on materials dispensed within gelatine capsules.Coating serves a number of purposes right from protecting stomach lining from aggressive drugs to protecting the tablet from stomach acids. It also helps in maintaining the shape of the tablet and thus can offer a delayed release of the medication.

Coating Pan

Get Price Quote

Used for coating of tablets/ granules. The pan is mounted in inclined position for effective coating. Unit is provided with suitable hot air blower to get desired temperature which can be controlled by thermostat. Used in pharmaceuticals bulk, drug and chemicals, foods Industries.Available Sizes :- 12” TO 72” M.O :- M.S, S.S.304, S.S.316, S.S.316 L

Electrophoretic Coating Machine

Get Price Quote

1 Piece (MOQ)

The E-Coating process is a mixture of Plating process and Painting, where a DC voltage is passed through thework piece while immersed in a water based solution with a paint emulsion. The process results in the paintto adhere to the surface of the piece and form a layer. Moreover, creating attractive designs, E-Coating processes is used for getting Corrosion protection, Smooth and Lasting Finish. A Source of DC Voltage is a primary requirement for E-Coating process.That is where the role of E-Coating Plant comes in. E-Coating plant has great advantage over a simple voltage source since it has provisions to adjust voltage to required values.Temperature and Timer Control and in built Magnetic Spinner for glass beakers, making it perfect assistance inE-Coating process. Features :- Capacity : 2 Litres Equipped with Pyrex 2 Litre Glass beakers Heater : 300W Voltage adjustment through digital display and Stirrer to stir the solution ATP Anodes for Coating process Terminals provided with easy access

SOLID PAN AUTO COATER

Get Price Quote

Newly designed solid wall coating equipment is the core of a modern solid dosage line which makes it possible to do uniform coating of film & sugar for tablets, pellets and micro granules. It enables to achieve coast saving production by reduced energy & solution consumption. This technology is developed and widely accepted in European countries. POWDER DOSING TECHNOLOGY : Unique Powder Dosing System allows enlargement and layering of pellets, tablets (if required by the formulation), micro tablets and micro granules by means of excipients or active ingredients in powder form. The system shall be screw type fitted with suitable gear motor. The whole system shall be controlled / operated through PLC / MMI and the speed shall be controlled through Variable Frequency Drive (VFD). EQUIPMENT MANAGEMENT BY MEANS OF AUTOMATION: According to customers requirement, we offer advanced automation by using advance programmable logic controller & touch screen graphical man machine interface to monitor process & control automation like air, distribution, temperature, humidity auto cleaning process, security by interlocking, auto loading & unloading and CIP / WIP. The machine is design for Automatic System for product loading and unloading without damaging the product. The ideal solution spraying facility for film and sugar coating of tablets and micro granules includes two separate spray pumps with quick changeover facility. Both the spray units are fitted in a sound proof cabinet. FILM COATING : Film Coating system comprising of chokeless, Spray Gun & compact Peristaltic Pump for constant flow rate. SUGAR COATING : Sugar Coating system comprising of airless Spray Gun, Pneumatic high pressure piston type pump with recirculation system SALIENT FEATURES : Single equipment can handle tablets, pellets & micro granules. Pore less Pan for Film Coating and Sugar Coating helps in saving of coating material. Multifunction system by means of constant and homogeneous one way air flow into the bed of cores. Interchangeable ventilation system of inlet / outlet air duct connection. Easily fitted or removable type spray guns both for sugar and film coating for quick calibration, adjustment & safe cleaning. Air less sugar spraying system by using pneumatic high pressure piston type pump with spray gun and recirculation system. Film spraying system with air by using low pressure type peristaltic pump. User friendly operator interface by the means of touch screen MMI. Specially designed Air Distributing System and the intake and exhaust pipes can be interchanged according to the process needs. The different type of air paddles equipped for different material can be embedded into or taken off from the material. Automatic tablet loading & unloading system to avoid contamination. High efficiency, energy saving, safe, user friendly PLC base Controlled Technology. Cost saving production by reduced energy and solution consumption. The advance integrated fully automatic PLC programmed CIP system designed for fast & effective cleaning to avoid cross contamination. System is having multi wash system like cold water, hot water, detergent wash and air purging. High-Pressure multi stage pump is provided to give desired pressure to water for effective cleaning with auto drain system.

wire coating machine

1,500,000 Per Piece

tablet coating machines

Get Price Quote

Pioneers in the industry, we offer Tablet Coating Machines such as Coating Machine for Tablets and Tablet Coating Machine from India. We hold expertise in offering high quality Tablet Coating Machines (GMP Model SMS 09) to our esteemed customers. The product, offered by us, is precisely engineered from high quality metals and alloys. Suitable for sugar or film coating of tablets or granules & colouring of tablets.Contact parts S.S. 316 and non contact parts S.S. 304. Ploshing can be interchanged with coating pan and can be supplied with hot air blower. Optional spray coating system. is also available

pvdc coating machineS

Get Price Quote

Webflex Machines is known as the best manufacturer & exporter of PVDC Coating Machine. Webflex Machines is known for providing quality products. PVDC Coating Machine from our repertoire is one of the popular machines amongst our customers. We have acquired best raw material of metal, alloy and developed PVDC Coating Machine of high quality. This machine is manufactured indigenously and hence can be customized as per customer’s requirement. It is used for various PVDC Coating applications. We abide the industrial norms while manufacturing our products. We have a vast network of distributors and this enables us to deliver all our machines as per set deadline. PVDC coating machine is durable, easy to operate and maintain and is competitively priced.

Wok with Non-Stick Coating

Get Price Quote

tablet coating system

Get Price Quote

we have manufactured Tablet Coating System that is used in various pharmaceutical industries. Automatic Tablet Coating System offered by us is fabricated using latest technological procedures. Designed for the purpose of coating granules, tablets and pallets, our Perforated Tablet Coating System is known for its high-precision and performance. In addition to this, we ensure availability of Perforated Tablet Coating System in different specifications and grades suiting to the preferences of clients. We are counted as one of the major Perforated Tablet Coating System Manufacturers from India.

Hot melt coating machine

Get Price Quote

Hot Melt Coating MachineEquipped with a hot melt pre-melting and recirculation tanks.A rotogravure coating trolley is standard and a semi-flexo trolley is optional.This machine is suitable for producing soap wrappers (full and registered coating), chewing gum wrappers, bread wrappers,etc.

vmch coating machine

Get Price Quote

We are the popular manufacturer of VMCH Coating Machine. VMCH coating is done on Aluminium Foil. Colouring or Lacquering is of Aluminium, Metallized Film. VMCH Coating Machine from WebFlex Machines are popular in India & exported worldwide. Gamut of experience of our professional R & D staff has helped us to develop super quality VMCH Coating Machine. As is our forte we sell customized machine to our customers and these coating machines are popular for easy installation, smooth operation and easy maintenance. VMCH coating machine manufactured by us have multiple segments of industry for VMCH coating.

Four Sided Film Applicator

400,000 Per Piece

Automatic Emulsion Coating Machine

Get Price Quote

GRAFICA introduces for the first time in India a most efficient, easy and maintenance free "Double Sided Emulsion Coating Machine" with online drying system. Sharpness, repetition accuracy in all four color printing & in fine line printing even emulsion thickness and flat surface of emulsion layer from the print side is generally required in making high quality screens. Our Automatic Emulsion Coating Machine is engineered to make high quality screen with ease, as no skill required operating the machine. With GF 3040 EC you can achieve multi color screens with same kind of repetition accuracy as desired. Specifications : Available with Micro Processor System & User Friendly Control Panel 5 Different Program Memory Double Sided Coating System

Coating Pan

140,000 - 145,000 Per Piece

Coating Pan

Get Price Quote

The coating pan basically consists of a pear shaper S.S. pan mounted on an angular structure. The pan is directly coupled to a suitable gear box. The gear-box and motor are coupled through a suitable belt driven assembly with 2 step pulley. The complete assembly is housed inside a suitable tubular framework with S.S. cladding. The complete assembly is provided with a hot air blower with electrical heaters for drying the sprayed solution. An electrical panel houses the various controls for the main drive, blower, digital temperature Granulation Line:- coating pan is a conventional system for film / sugar coating of tablets, capsules, peppermints, and similar other products. An electrical panel houses the various controls for the main drive, blower, digital temperature. Features: Pear shaped designed facilitates in the complete coating of the product Optionally provided with baffles inside the pan for reversing of the tablets. Different speeds available for different applications. Faster drying due to the hot air blower.

Color Coating Line

Get Price Quote

Color coating is a processing of coating sheet with organic paint. The coated sheet has good characteristic such as easy printing, processability, corrosion resistance, decoration, as well high strength and good deformability. We can provide the following lines, CCL for building, CCL for home appliance, CCL with fluorocarbon, decorative or insulation coating, Color Printing Line, as well as CCL with fingerprint resistance coating or bacteria resistance coating etc, according to your requirements

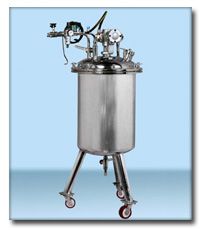

pharmaceutical coating machine

Get Price Quote

This is conventional and complete system to connect any Coating pan and most suitable for the rapid and uniform coating of Tablets, Granules & Pallets. CAPACITY AVAILABLE : 10 25 50 100 150 Ltrs. TECHNICAL SPECIFICATION : The system consists of a stainless steel 316 quality pressure vessel provided with S .S. jacket with electric heaters and thermostat control and provided with safety valve, pneumatic oscilating type stirrer fitted on top of the vessel. System available with plain vessel for Film Coating & Jacketed vessel for sugar coating.

spray coating machine

Get Price Quote

This is conventional and complete system to connect any Coating pan and most suitable for the rapid and uniform coating of Tablets, Granules & Pallets. The system consists of a stainless steel 316 quality pressure vessel provided with S .S. jacket with electric heaters and thermostat control and provided with safety valve, pneumatic oscilating type stirrer fitted on top of the vessel.

Warp Around Hot melt labeling Machine

Get Price Quote

The Wrap around Hotmelt labeling machine is a high speed system ideal for round bottles. It is matched with R.F.C machine and the conveyor connecting both is synchronized to ensure smooth flow of bottles. A stainless steel star wheel or feed worm in case of high speed machines will take the bottle and place in front of the label application drum. The label is delivered by the sensor controls whose response time and control speed frequency of the electronic print mark registration system is very fast, and it works 20 times faster than any other Indian Hotmelt label applicator. The bottle is rolled over the label and on completion of label application, bottle will be discharged on the out feed conveyor. The synchronizing/correction speed is 350 MHZ and response time is 120 micro-seconds. For lower capacity machines to save cost we have developed our own Hotmelt unit, but for higher speed machines we use a Nordson, (U.S.A) system. All electronics used in our system are from leading suppliers such as Siemens, LG, Danfoss who have worldwide service support. The electronic registration system is servo controlled and the fly cutter is synchronized to it to ensure that label is cut with ±1 mm of the print mark. The label cutter is PLC controlled with a hardened tool steel blade. There is an alarm when the label reel starts to run low. If there is no bottle on conveyor, the label will not be delivered to the drum and if there is no label on the drum no adhesive is applied

tablet coating system

Get Price Quote

color coating machine

Get Price Quote

Specially designed powder coating machine for multi-color operations. The M700 Dipstick™ delivers color changes in 15 seconds. It comes with an ‘Infiniti™’ powder spray gun, a control panel with a performance monitor, a Dipstick™ and many other features the make it the best choice for multi-color coating applications.

pvd coating machine

Get Price Quote

Physical vapor deposition (PVD) is a variety of vacuum deposition and is a general term used to describe any of a variety of methods to deposit thin films by the condensation of a vaporized form of the material onto various surfaces. The coating method involves purely physical processes such as high temperature vacuum evaporation or plasma sputter bombardment rather than involving a chemical reaction at the surface to be coated as in chemical vapor deposition. Physical Vapor Deposition (PVD) is an environmentally friendly vacuum coating process that provides brilliant and durable decorative finishes on household appliances, stainless steel sheets, door hardware, jewellery, electronic components, automotive trim and marine fittings.

Adhesive Coating Machine

Get Price Quote

Adhesive Coating Machine, Silicon Coating Machine

Powder Coating Machines

Get Price Quote

Powder Coating Machines

hot melt machine

Get Price Quote

hot melt machine, Bag Making Machine, Rotogravure Printing Presses

DRUM COATERS

Get Price Quote

DRUM COATERS, fluidized beds, SPOUTED BEDS, HIGH SHEAR GRANULATORS

Coating Pan

Get Price Quote

Coating Pan, Sigma Mixer Machine, Flaker machine, Octagonal Blender

Hot Melt Adhesive Spraying Machine

Get Price Quote

Hot Melt Adhesive Spraying Machine, Back Glue for Book Binding