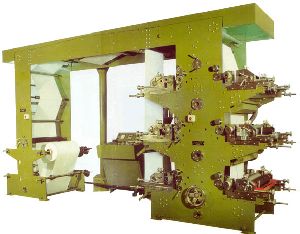

Four Color Flexographic Printing Machine

125,000 Per Piece

Single Color Inline Roto Printing Machine

Get Price Quote

Product Description: Performance and Use: The single color printing machine is manufactured according to requirement of your enterprises, which is mainly used in film blowing machine and has the feature of rapid convenient and efficiency, and completed with film blowing machine. Technical Specifications: Model SPR - 500 SPR - 600 Printing Colors 1 Color 1 Color Printing Width 500mm 600mm Printing Speed Rate decision bythe blown film Rate decision by the blown film Total power None None Dimension of the machine 930x250x750mm 1050x300x750mm

Best Deals from Color Printing Machine

Six Color Flexo Printing Machine

1,500,000 - 15,000,000 Per Piece

1 Piece (MOQ)

6 Color Pad Printing Machine With Carousel

Get Price Quote

1 piece (MOQ)

Our 6-Color Pad Printing Machine with Carousel offers precise, vibrant multi-color printing for various substrates. Featuring a rotary table for continuous operation, user-friendly touchscreen controls, robust construction, and advanced ink management, it ensures high productivity and versatility for industries like automotive, electronics, medical devices, and promotional products.

One Color Flexo Paper Printing Machine

Get Price Quote

We are the leading manufacturers, exporters and supplier of this products.

Six Colour Flexographic Printing Machine

Get Price Quote

We offer Six Colour Flexographic Printing Machine that has Duplex Unwind & Rewind system. The Six Colour Flexographic Printing Machine, offered by us, is acclaimed for high performance, energy efficiency and durability. Six Colour Flexographic Printing Machines can be availed in different configurations from us. We are a prominent Six Colour Flexographic Printing Machine Manufacturer and Exporter in Maharashtra (India).

Double Color Pad Printing Machine

Get Price Quote

1 Piece(s) (MOQ)

ROLL TO ROLL SIX COLOR FLEXOGRAPHIC PRINTING MACHINE

Get Price Quote

The range of application covers particularly the printing of flexible packaging means such as Low Density and High Density polythylene, polypropylene, polyester and co-extruded film, tissue paper, BOPP, etc... Click for Enlarged View

single color printing machine

3,750,000 Per Piece

Features : Low maintenance Easy operation Hard-wearing High efficiency

Color Flexo Printing Machine

325,000 Per Set

1 Set(s) (MOQ)

This machine is specially designed for higher production and sharp and clear printing on paper. It prints using photo polymers stereos (2.8 mm and 4.8 mm) and water based inks. It is equipped with anilox and rubber to controls optimum ink transfer ensuring clear and sharp printing result. This sheet fed machine is equipped with hard chrome plated main shell (stereo mounting cylinder) & pressure roller, digital counter & sensor. Self lock break system is provided avoiding wastage of paper, if sheet is wrongly fed. This heavy duty and robust machine is available in single, double, three and four colours. The machine shall optionally be quipped with ac variable speed drive with portable remote & control panel, centralised oil lubrication system & ink circulation system

Six Color tube Printing Machine

Get Price Quote

1 Piece (MOQ)

We are offering the six color printing machine is equipped with special made frame and chain gear, allowing it to be connected with base color printing machine and tube capping machine. No printing will be performed if the machine runs out of tube. Main specification aluminum tube diameter: φ11mm-φ38mm aluminum tube length: 55mm-175mm production speed: 60 pcsmin axis diameter: 12.25±0.02mm

Single Color Flexo Printing Machine

510,000 Per Piece

Color Printing Machine

650,000 Per Units

Rewinding Machine with 1 colour Rotogravure Printing attachment

Get Price Quote

color Solvent Printing Machine

Get Price Quote

Single Color Flexo Printing Machine

Get Price Quote

Customers should stay rest assured with us for the payment procedures. They can pay us conveniently through wide-ranging payment mediums. Based in Maharashtra(India), our organization caters to the numerous requirements of the customers related to our products.

Four Colour Dry Offset Printing Machine

Get Price Quote

This Four Colour Dry Offset Printing Machine is designed for high quality printing at a high speed. This machine is design in 10 stations turret with manifold indexer mechanism. The inking devices can work together or separately. The machine can be adjusted for three, two or single Colour Printing. The ink distribution can be regulated on one side, with adjusting for three, two or single Colour Printing. The ink distribution can be regulated on one side, with the adjusting screws of the distributing roller and on the other side, through the ink adjustment on the Ductor Blades. All the Machine adjustment points are easily accessible and each Printing unit can be set independently of the other. For fine register adjustment is provided with the Plate rolls both axially and radially. The individual rubber inking rolls are easily detachable. The Zinc Plates are fixed firmly on both ends by means of retaining bars or rolls. The Printing Blanket is fixed securely at both ends to the Printing Cylinder and can be easily inserted.

4 Colour Closed Cup Pad Printing Machine

Get Price Quote

Key Features of TPS-90 FX � Closed Cup Machine � Flexibility in print area � 100 % FESTO Pneumatics � Four colour “Wet on Wet” printing facility � Robust mechanical controls � Proximity switch & Microprocessor based � Works on Single Phase Supply � Automatic Unloading Facility � Easy Registration of image � High Output as compared to shuttle

Single Color Flexo Printing Machine

Get Price Quote

SHEAR LINE Flexo Printer is designed to help corrugated box manufacturers to keep pace with the demand for sharp and excellent printing on corrugated boxes. Incorporating the latest technology, Shear Line - Flexo Printer prints better and dries faster resulting in increased production.

Six Colour Flexographic Printing Machine

Get Price Quote

Re-circulation of hot air which provides for expelling calculated quantity of air, to control solvent level and yet achieve faster drying coupled with tremendous saving of energy.