Bar Threading Machine

150,000 Per Piece

1 Piece(s) (MOQ)

3 Kg SS Body Rectangular Vibrator

Get Price Quote

1 Piece (MOQ)

Doit Industries Rectangular vibrators are devices designed to perform smoothing, finishing, and polishing of Jewellery of a Variable range of sizes using Abrasive Materials with the vibration effect of the Vibrator. The Motion of the Abrasive Material along with the Action of Water and detergent results in top-grade finishing.

Best Deals from Construction Machine

Vibration Table

Get Price Quote

Specifications It is designed to carry a load of 140 kg. The apparatus consists of a motor fitted with a Variable pitch pulley housed in a cabinet. The vibrations are imparted by means of off-balance masses rotating on a shaft of a Vibrator clamped to the underside of the table top. The table top is 50cm x 50cm. and has stops along its edges to prevent moulds from Walking off the table during vibration. A cross arm adjustable on a vertical rod at the center of The table is provided to hold the moulds while operating the table. The variable pitch pulley arrangement permits the frequency to be varied sleeplessly Between a maximum of 1400 vibrations per minute. Digital Frequency Indicator + controller with resolution of 1 Hz Digital indicator for amplitude measurement. Electric Supply of 440 volts, 3 phase, 50 Hz Vibrating Tables of table top size 50cm x 50cm as well as 1000cm x 100cm are also available. (OR as per customer’s choice.)

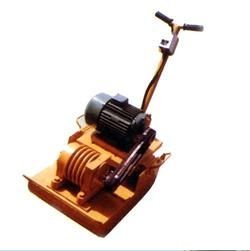

Reversible Vibratory Plate Compactor

72,000 Per Piece

1 Piece (MOQ)

Scrap Car Bicycle Shredder Waste Steel Iron Aluminum Metal Crusher Machine

300,000 - 500,000 Per piece

1 Piece (MOQ)

SHREDALL Scrap Car Bicycle Shredder is Ultimate Solution for Waste Steel, Iron, Aluminum, and Metal Recycling. Our crusher machine efficiently shreds scrap cars, bicycles, and metal waste into reusable materials. Perfect for recycling centers and metal processing plants. Turn your waste into profit with our powerful shredder. "Transform scrap cars, bicycles, and metal waste into valuable resources with our Scrap Car Bicycle Shredder. Our efficient crusher machine swiftly shreds steel, iron, aluminum, and other metals, making recycling easy and profitable. Perfect for metal recycling facilities, our shredder ensures maximum efficiency in waste management. The Working of Metal Crusher Machine The metal crusher machine operates by crushing scrap metal into smaller pieces, facilitating easy recycling and reuse. It utilizes a powerful mechanism to break down steel, iron, aluminum, and other metals efficiently. This process reduces waste volume and prepares materials for recycling. Ideal for metal recycling plants, our crusher machine maximizes efficiency in metal waste management, promoting environmental sustainability and resource conservation. Key Features - Powerful crushing capability for steel, iron, aluminum, and other metals. - Versatile, suitable for shredding scrap cars, bicycles, and metal waste. - Compact design saves space in recycling facilities. - Durable construction for long-term use. - Easy maintenance and cleaning. - Safety features prevent accidents. - Eco-friendly, promotes recycling. - High efficiency for fast metal shredding. - Customizable to meet specific needs. - Reliable performance for continuous operation. Shredding Material Capable of shredding various materials including scrap cars, bicycles, steel, iron, aluminum, and other metal waste with ease. Versatile and powerful, our shredder handles diverse materials for efficient recycling. Shredding Machine Type It's a double shaft shredder, designed for maximum efficiency in shredding various materials. With dual shafts, it ensures thorough and effective shredding in a single pass. Usage/Application Ideal for recycling centers, metal processing plants, and waste management facilities. Capacity With a shredder from 1000 kgs/hr to 10,000 kgs/hr, the machine is available for small, medium to large-scale operations. Automation Grade The Shredder Machine is fully automatic, which makes it easy to operate. Motor Power The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance. Country of Origin Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess. High Performance and Easy Installation High performance and easy installation make this shredder perfect for any recycling operation. With its powerful capabilities and simple setup, it's a reliable choice for efficient waste management. Product Description Introducing our high-performance double shaft shredder, designed for efficient waste management. With easy installation and robust construction, this shredder is perfect for recycling centers and metal processing plants. Versatile and powerful, it efficiently shreds various materials including scrap cars, bicycles, steel, iron, and aluminum, promoting sustainability and resource conservation.

3 HP Electric Cement Grouting Pump

68,000 Per Piece

e, RIDDHI ENTERPRISE, are one of the eminent manufacturers of a wide range of Pumping Systems. Extensively used in various industries like automotive, infrastructure projects, agriculture and construction, the products are appreciated for their efficiency and reliability. We mainly manufacture and supply High quality, High pressure Injection and Grounting Pumps, Standard cement Grouting pumps, Epoxy resin and PU Injection Pumps, Industrial Injection Packers, And all other Grouting tools and accessories which are used for civil Construction and Rehabilitation works.Backed by a sound infrastructure, equipped with latest technology and innovation, we ensure that the products are at par with industry standards. Our expert technicians make sure the most advanced methodology is adopted to design our product range. To maintain high standards of our products, the quality controllers thoroughly inspect each & every product before it gets delivered to the clients. We are also instrumental in offering after-sales services to our clients within specified time frame.The catalyst for the success of our organization is the support of our mentor, Mr.NILESH SHAH. Under his able guidance and constant encouragement, we have scaled new dimensions of success and acquired a rich clientele across the nation.

Case 1107 Ex Soil Compactor

Get Price Quote

Centrifuge Machine

Get Price Quote

Our Centrifuge Machine is highly appreciated in the global market for its rugged construction and sophisticated design. It helps to remove air bubbles from refills and sets gel with ink. It is equipped with a fan, a dynamically balanced machine is driven by 2 HP, 3 HP A.C motor. Further, it is controlled by A.C variable drive and PLC controller for accurate R.P.M and perfect timing. Both time and R.P.M is adjustable i.e. RPM from 500 to 1800 and in 1 second can be adjust. Our durable Centrifuge Machine contains 4 stage of centrifuge process to produce better results.Find here Centrifuge Machine Manufacturer in Mumbai Maharashtra, offered by Panchal Engineering Works is one of the leading in the market for supplying quality based Centrifuge Machine. Salient Features : Easy to operate Technically advanced design Long functional life Competitive price Capacity : Approx. 1000 pcs at per cycle of 5 mm refill

Top Backhoe Loader

100,000 - 400,000 Per piece

1 piece (MOQ)

Concrete Cube Mould

900 Per

300 Piece (MOQ)

RCC Grill Mould

5,000 Per Piece

1 Piece (MOQ)

salt crushing machine

Get Price Quote

Potato Peeling Machine

10,000 - 85,000 Per piece

1 Piece (MOQ)

Wall Putty Making Machine

Get Price Quote

1 Piece (MOQ)

Features of Wall Putty making machine Easy cleaning. No pre-mixing. Low noise level. Low maintenance cost. Safe and easy performance. High viscous materials can be dispersed. Economical, consume less power per liter of materials.

GA-M 250 Crush Cutting Machine

Get Price Quote

We are offering Web width upto 250mm. Equipped with both razor blade 7 pneumatic crush cutting. Duplex differential rewind with two turrets on 76mm ID cores. Tension control through individual pneumatic clutches. Speed -150 metres/ min.

Hydraulic Bar Straightening Machine

65,000 Per Piece

1 Piece (MOQ)

Sand Washing Machine

Get Price Quote

We are instrumental in providing our clients with Sand Washing Machines that are widely used for removing impurities such as silt & salt from the sand. All impurities are needed to eliminate from the sand, because these decrease the concrete quality. Previously or in present scenario, our machine is widely used to wash out impurities from the sand by sprinkling water on the heap of sand. In addition to this, the sand is thoroughly washed out in a tub of our machine with churning action that eliminates the silt & other impurities efficiently.

Building Fire Escape Cradle

3,000,000 - 5,000,000 Per Set

1 Set (MOQ)

Building Fire Escape Cradle which is also Known as lowring device be used in case of fire in the buildings and to escape from the building fire this emegency Lowring Devcie cradle is used. We are engaged in offering Aerial Work Platform Cradle, which is extremely praised in the market.

Plastic Small and Lower Output Crushing and Grinding Machine

50,000 - 2,000,000 Per piece

1 piece (MOQ)

Heavy Pyramid Type Plate Bending Roller Machine

Get Price Quote

Three Roll Pyramid type Plate Bending Roller to bend 2500mm length x 25mm thickness mild steel plates with 30 HP 440 volts 3 phase AC electric motor, OnOff push button starter and Reverse Forward Switch. We can offer you our best quality, heavy duty steel fabricated body three roll pyramid type plate bending machines as per your requirements. We can supply you both mechanical and hand operated plate bending machine. Machine is supplied with centralized lubrication system. Heavy duty steel fabricated housing amply proportioned to withstand maximum strain. Rolls are of forged EN-8 material and run in collar type gun metal bushes. Base is of heavy duty girders. Drive through a series of hob cut steel gears and worm reduction gear box. Screw jack is provided to keep the top roll in horizontal position when trunion is retracted to facilitate removal of formed shells. The photo shows our standard 2500mm x 25mm capacity bending roller fitted with 30.0 HP three phase AC electric motor, Siemens make ONOFF Push Button Starter with Siemens make ReverseForward switch. We can supply machines to bend sheets upto 32mm Plate. We also offer light duty motorised and manually driven three roll plate bending roller machines as well. Kindly ask for more details.

Vibrating Plate Compactor

28,000 - 65,000 Per Set

1 piece (MOQ)

We are engaged in designing and developing Vibrating Plate Compactor that meets with international quality norms & standards. All our products are designed and developed using superior raw material and latest machinery that are sourced from the reliable vendors of the market. In addition to this, we have the capability to customize all the products as per the specifications laid down by the customers. Features High tensile strength Immaculate performance Less fuel consumption

DOUBLE PISTON MORTAR SPRAYING MACHINE

Get Price Quote

High Speed Pan Mixer

Get Price Quote

Based in Mumbai, Maharashtra, we are a well-known Manufacturer and Supplier of High Speed Pan Mixer. Our precision-engineered High Speed Pan Mixer is available in different specifications to meet diverse applications. Employed for producing high quality concrete both light and heavy of all consistencies, our High Speed Pan Mixer is applauded for high quality, efficiency, reliability and durability. It is duly tested on various parameters to ensure hassle-free operation. We offer this machine at market leading prices. Advantages Extremely low wear Low power requirement Ease of access to the mixing pan for maintenance and cleaning work Hydraulically actuated discharge at up to three possible position Off-set by 90 degree to each other Steam injection for the production of hot concrete Turbo-type cuth for economic starting when mixing pan is filled No environmental pollution Minimum operation noise due to special rubber wear part Outstanding constant mixing action High output per hour Other Applications Sand lime mixtures Refractory clay mixture Glass mixture Ceramic mixture

Concrete Mixer

Get Price Quote

2 Piece(s) (MOQ)

We offer concrete mixer.

Vertical Decoiler

80,000 - 200,000 Per Piece

1 Piece(s) (MOQ)

The Machine is equipped with screw operating, self centralising expanding mandrel, manually operated by a built in adjusting handle. Four coil support arms give quick loading and well balanced coil location. The front coil retaining disc is fitted with a fast action hand lever lock for rapid coil changing. A non motorised Machine include an adjustable drag brake while in a Motorised Machine motor-gear box drive operated via an adjustable torque limiter to ensure safe operation.

pyramid type plate bending machine

Get Price Quote

The PBM series 3 Roll Pyramid Type Mechanical Plate bending are designed to cater the basic requirements of bending & forming of metal plates. In this machine, the bottom roles are driven by electric motor & gear box. The upper roll is having manual up & down adjustment to achieve desired bending radius. This is a very simple robust design machine suitable for light to medium jobs.

FABRIC PREPARATIONS MACHINES

Get Price Quote

The B-Tex Big-Batching Machine, BIM-BB is a combination of small processes to join small fabric rolls to big batch.With years of experience and number of Installation,We are confident to supply many possible process in one machine.BIM-BB can make big batch fabric small rolls with additional equipments like Conveyors , Anti-Weighing, Auto-Sewing operation, Inspection Table with Lights , Brushing and Beating Unit, J-Scray with Plaiter & Big-Batch output option. This BIM-BB saves lots of space,manpower,time and number of operations are possible in one go. simple Roll to Batch machine can also be supplied for fabric width from 150 cms to 600 cms. BIM-BB is fully tailor-made machine and allows to join any possible process in same machine. Benefits Suitable for all types for fabric Woven, Non-Woven & Technical Fabrics Number of process can be incorporated like Sewing, Brushing, Inspection, J-Scray, etc. Conveyor can be supplied for continous process Fabric can be delivered in Big-Batch and Plaiter also. Saves number of manpower, space and Time

LSX Sand Washing Machine

Get Price Quote

TQMC LSX series screw sand washing machine is designed to bigger capacity and higher cleaning level than traditional washing machines. It sets three functions—washing, dewatering, classifying—as a whole, saving the labor and working site space. Now this series sand washing machine has been widely used in various industries. Features Long service life and no quick-wear part, leading to low investment cost and operation cost High capacity and less loss of fine products Transmission bearings of impeller depart from water and material, avoiding being eroded. Higher washing-cleanliness than traditional ones Set functions as a whole, reducing investment costs of other machines

Plate Rolling Machine

Get Price Quote

To keep a strict check on the quality of the products, we have hired professional quality analysts having rich domain experience. A famed name, the company is enlisted amidst the well-known Suppliers of Plate Rolling Machine.

Road Sweeping Machine

873,000 - 1,081,000 Per No

1 Piece (MOQ)