Semi Automatic Container Filling Machine

Get Price Quote

Semi Automatic Container Filling Machine (for Creams and Ointments) A simple and sturdy semi-automatic container filling machine for filling cream, paste, ointment, wax polish, grease, jam, sauce etc. in plastic or tin containers or jars, bottles etc. Containers like flat tins, bottles are to be manually placed under the filling nozzles. No-Container-No-Fill device will stop the machine if container is not in place. SS jacketed hopper with 2 kw heater and stirrer can be provided as an option to facilitate easy filling of highly viscous products. Filled containers are to be manually removed from machine and replaced with next empty container.FEATURES: Can fill creams of various viscosity No –Container – No – Fill interlock Tail Cutting arrangement after dozing Easy change over from one size to another Fill quantity can be accurately adjusted Fill accuracy up to ±0.5% Simple in operation and maintenance Compressed Air Requirement: 2 CFM at 6 bar pressure Fill Range with interchangeable Filling Syringe of different capacity# Output depends on fill quantity, material characteristics and operator comfort.

container sealing machine

Get Price Quote

Shah & Co. provides various types of container sealing machines, which ensures you high reliability as well as durability. Our machines have a lot of power and thus can perform each and every task in the matter of few seconds. We provide highly valued container sealing machines at minimum market price.

Best Deals from Container Making Machine

Container Making Machine

1,500,000 - 5,000,000 Per Unit

1 Unit (MOQ)

Automatic Container Filling Machine

Get Price Quote

Desilting Machine With Tipping Container

Get Price Quote

Mac Lifton Desilting cum dumper is a two in one machine a new concept in open drainage cleaning. The two in one machine is designed to clean open drains with the help of its excavator like arm. The silt is then loaded on to the container provided on the vehicle and then dumper at the dumping site.These machines are suitable for lifting and removing accumulated deposits of silt, debris, grit, pebbles. stones rubbles, grass, animal dung, twinge, vegetables, small branches of tree etc. for establishing the free flow in the drains.

Container Shape Forming Machine

Get Price Quote

Hydraulically operated container shape forming machine, for shaping Square and Rectangular bodies after electrically welded cylindrical Tin-Plate Bodies with 5 KW, 2-850 RPM complete with starter and other accessories, oil tank of adequate capacity mounted on a suitable frame work for keeping in the production line with one set of dies suitable for Square or irregular containers.

Body Maker

Get Price Quote

Mechelonic Engineers has now introduced the second generation, fully automatic container side seam welding machine with medium speed production. Machelonic engineers system of container welding is well established for producing continuous, constant narrow weld at optimum working speed, using copper wire as intermediate electrodes. ApplicationsThe machine is designed for medium speed automatic welding of tin sheets in container manufacturing. This machine has flexibility of design to accommodate different sizes of cans from 72 to 450mm length(body height) FeaturesThe machine is fully automatic combining various stages of manufacturing like destacker feeder, flexer, roll forming, overlapping the edges for welding of side seam, transport to welding station, wire drive, welding station, ejection of welding shells and wire collector. ConstructionCompact main frame of welded construction having streamlined appearance. The main transformer, variable speed drives, electronic control system etc. are enclosed in the frame and are easily accessible for serving. Main transformerSpecially designed class ‘F’ insulated transformer, water cooled and fully tropicalised for withstanding continuous operation. Destacker FeederPneumatically operated oscillating arm with a set of vacuum suckers, provided on the machine destacks the blanks and delivers them to flexer rollers. This process is monitored by electronic control system to give command for further operation. A hydraulically operated table is provided for stacking body blanks. This table automatically raises to adjust the level of body blanks for feeding to the flexer. The machine is provided with manetic sheet floaters and air jet separators to facilitate single sheet feed to flexer rollers. FlexerThe body blanks fed to flexing rollers are flexed and moved to roll former. Flexure is provided with rubber coated rollers to avoid damage to printed surface of tin sheet. Roll FormerThe flex banks are automatically moved into the roll former and rolled into desired shapes. Roll former has arrangement to adjust the body rolling diameter within specified range. Centering FlapsThe rolls blacks are collected by a set of pneumatically operated flaps, which also guides edges of rolled body in catch bar. A separate set of flaps are required for each range of body diameter. Crown AssemblyThe crown assembly near welding station controls exact diameter of body before welding. This assembly can be calibrated outside the machine on a setting mandrel. Calibrating Ringfor welding with narrow overlap (0.5mm), calibrating ring assembly provided on the machine will maintain parallel overlap.One set consisting of crown assembly, crown setting mandrel, centering flaps and calibrating ring will be provided with machine for a specific size of can as standard. Other sizes will be available on additional cost. Upper ArmThe upper arm is manufactured from special grade high tensile brass of suitable cross section to minimize any deflection during normal operation. The upper weld wheel and Z- bar are fixed to this arm. Arm is water cooled.Note: tooling for 301 and 302 at extra cost: Tooling for 301 and 307 together with a small arm could be supplied as aspecial case provided the customer uses Tin plates of Temper T3. Catch- Bar and Z-BarThe machine is provided with catch-bar and Z-bar to control overlap and also to guide the shell, while welding. Welding StationWelding station consists of two anti-fiction type weld wheels, made of special copper alloy with mercury contacts. These weld wheels are water cooled. A specially made weld wheel holder for lower weld wheel is provided. Welding pressure is provided by lower weld wheel. A single copper wire running over weld weld wheels act as intermediate electrode. The formed body of can is transported to welding station. The arrival of can is sensed through an electronic system and welding initiates and completes automatically. In this machine welding is at the bottom of can. Wire Flattening UnitA controlled drive with rollers, flatten the copper wire to the required flatness before entering the wire feeding system. Wire Feeding SystemAn accurate variable speed drive with electromagnetic clutch brake system and control wire tensioning devices provide positive and precise fed control of copper wire. Ejection of Welded ShellsWelding shells are received on a magnetic conveyor and ejected on the main conveyor. Wire controlling SystemThe copper wire used as the intermediate electrode for welding is wound on a re-coiler. Control PanelA centralizedcontrol panel is provided with facilities like operating switches, pilot lamps, ammeter, current fine setting, batch counter and continuous counter of cans. Machine is also provided with additional facilities like single cycle mode and setting up mode. Operating cycleLoad body blanks on the table, adjust parameters on the machine, operate the start switch. The machine instantaneously starts and continues to weld the body blanks. The operator has to only ensure that the destacker table has enough stock of body blanks. The automatic function includes picking up of the body blanks, flexing roll forming, guide to the catch- bar and then to Z-bar and welding at the welding station. The welded bodies are automatically ejected out. Safety FeaturesSafety features like No Wire Detector, Wire Cut-off Detector, No Can Detector, No Guard Detector Weld Wheel Position Detector are part of the machine. Side Stripping System The Machine can be provided with Nordson internal and external liquid lacker stripping system, alongwith take of conveyor and suitable cutting system at additional cost.

Container Filling Machine

Get Price Quote

Optionally Available ➤ Automatic container feeding with turn table or packing conveyor ➤ Jacketed hopper & mixing stirrer ➤ Plugging & capping machine It’s ideally suited for filling of pharmaceuticals ointment, cosmetic, adhesive type resin & hardener, fevicol, cream, shaving cream, paste and other high viscose materials rubber adhesive, chyawanprash etc. Salient Features ➤ Dripless accurate filling. ➤ Filling accuracy ± 1% ➤ Filling range 5gm to 500gm ➤ very low space require ➤ lower maintenance require ➤ speed depending upon volume & viscosity of the product ➤ all the contact parts are 304 / 316 / 316L quality as per your requirement

Double Station Lubricants Container Plastic Blow Molding Machine

Get Price Quote

We are a noteworthy name and work hard to attain complete client satisfaction. And, for achieving this objective, we facilitate them with easy payment modes. Only high quality raw materials have been used for the production of our products as we comply with all quality standards.

Cutting and Punching Machine for HDPE Jumbo Container Bags

Get Price Quote

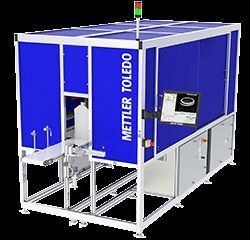

V27 Series for Rigid Plastic Container Inspection

Get Price Quote

Inspection of Rigid Plastic Containers The METTLER TOLEDO V27 series of inspection systems are designed to ensure the proper formation of rigid plastic containers.

Microcomputer Control Packaging Container Pressure Testing Machine

Get Price Quote

1 Piece(s) (MOQ)

We are offering microcomputer control packaging container pressure testing machine. microcomputer control packaging container pressure testing machine ■specification:10kn、20kn、50kn ■model:auto-104、auto-204、auto-504 ■application:this machine is mainly suitable for the packaging container of anti- pressure test and the stacking test , with a long time paul upload function,also it can carry out opposite angle and edge compression tests.

container filling

Get Price Quote

We are offering container filling machine. Empty containers are fed manually or automatically through turn table. The empty containers are carried by the belt conveyor up to the filling station.

container containerized block ice machine

Get Price Quote

aluminium foil container machine

Get Price Quote

aluminium foil container machine, Aluminium Foil Container

Container Filling Machine

Get Price Quote

Container Filling Machine, Semi Automatic Tube Filling Machine

tin container machine

Get Price Quote

tin container machine, die makers

aluminium foil container making machine

Get Price Quote

aluminium foil container making machine

PET Container Making Machine

Get Price Quote

PET Container Making Machine, Pet Bottle Molding Machine

Tin Container Manufacturing Machine

Get Price Quote

Tin Container Manufacturing Machine, Conjugate Cams, Metal Cap Making Machine

tin container machine

Get Price Quote

tin container machine, die makers, supplier of tin container machine

Aluminum Foil Container Making Machine

Get Price Quote

Aluminum Foil Container Making Machine, Cold Roll Forming Machine

Water Container Machine

Get Price Quote

Water Container Machine, Toys Blow Moulding Machine