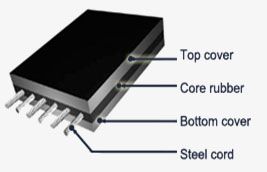

Steel Cord Conveyor Belts

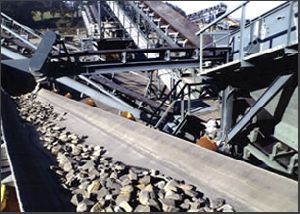

Steel Cord Conveyor Belts are suitable for conveying heavy load materials for long distance. Rubber penetrates perfectly among steel cords through open steel cord that minimizes corrosion of belts. Steel cords also ensure higher elongation allowing excellent energy absorption in the event of impact. Steel Cord Conveyor Belts are excessively used in the industries like: Agro Industry Chemical Coking Ginning Iron and Steel Industry Mining Industry Ports Power Plants Smelters Continental Belting Pvt Ltd is an ISO9001 (2015) certified company and we have been manufacturing Steel cord conveying Belts since 1984. Our products are qualified as per the standards set up by EN ISO 15236, DIN22131, SANS1366 and AS1333. Many high profile local Industries like ACC, Ultratech Cement, Steel Authority of India, Reliance Energy, Godrej, Thermax, Vedanta, UHDE, HCC, Adani, Gujarat Ambuja, JSW Steel, AIS Glass, Saint Gobain and many others are our satisfied regular clients. Our Steel Cord Conveying Belts are supplied to hundreds of cities all over India and are even exporter to more than 45 countries all around the world. Salient features: Industrial fabric is used to manufacture Carcass to make it rigid and practically unbreakable with an advanced design for superior energy distribution across belt width. Long service and working life even under severe conditions Best quality of raw materials like Industrial fabric, rubber, carbon black, zinc oxide, processing oil are used to ensure the features like: Fire resistant Cold resistant Abrasion resistant Heat resistant Chemical resistant Pelleted packing and Seaworthy packaging for exporting Have very low elongation and hence very effective for the purpose of large distance conveying

...more

Steel Cord Conveyor Belt

Used in coal, ore, port, metallurgical, power and chemical industries, suitable for long distance and heavy load transportation of materials. Standards offered are DIN22131, EN ISO 15236, SANS1366 and AS1333. Cover Compounds: General, Fire-resistant Cold-resistant Abrasion-resistant Heat-resistant and Chemical-resistant

...more

Sidewall Belting

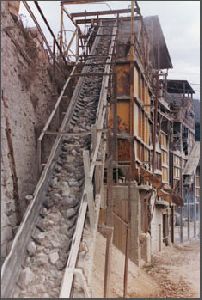

Since the late Eighties, Continental Belting ,has been committed to the development of World Class, Sidewall Conveyor Belts, and our products are now in use in practically all the Continents. We have been pioneers, and instrumental in popularizing this revolutionary technology, in India and overseas. We regularly produce sidewall belts upto 1800mm width. Right from the feed hopper to the discharge point, the belt is capable of turning through any angle up to a vertical line and back to horizontal. This eliminates the need for multi drives and prevents product degradation and spillage at transfer points Practically Zero Spillage Once the material is loaded onto the belt it is efficiently contained between the sidewalls and is prevented by the cross cleat from falling back. As the belt travels along the conveying line it retains the load within its own ‘side skirts’, eliminating spillage, but more importantly, as the sidewalls actually form part of the belt there is none of the wear normally associated with side skirts. The smooth transition when changing angle also ensures the material remains within the belt’s effective carrying area. Space Saving In areas where land is at a premium, i.e. dockside, or within existing plant where space is a problem, SIDEWALL CONVEYOR BELTS provides the ideal solution. With the ability to convey material at angles up to 90 deg. the required ground space is minimal. Minimum Maintenance - Long Belt In cost comparisons between mechanical elevators and SIDEWALL BELT systems it has been proven that the SIDEWALL BELT has considerable advantages. The belt itself requires no maintenance and the reduced number of moving parts plus simple conveyor construction virtually eliminates costly downtime. Wide Range of Materials can be Handled With the extensive range of belt sizes available, the SIDEWALL CONVEYOR BELT is capable of handling almost all materials: large lumps, free flowing, delicate or fragile substances, highly abrasive material, light weight or heavy loads. Our application engineers have the experience and a thorough working knowledge to specify the system to suit your needs. Low Power Requirement, Quiet Smooth Running A clear advantage of using an SIDEWALL CONVEYOR BELT system is the low power required to move the loaded belt. Because the system can elevate at steep angles (up to 90 deg.), centre distances tend to be small and even in high lift applications power required to elevate is considerably less than in other systems. As the belt is running on rotating idlers, the low resistance results in a quiet system, an advantage when operating in close proximity to personnel. Where environmental factors need to be considered, the system can be totally enclosed.

...more

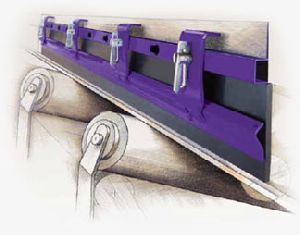

Rubber Skirting

Skirt Board rubber sheets are softer than the conveyor belt, so they do not create scoring or rubbing on the belt. Made for high quality Natural Rubber, having excellent wear resistance.

Thickness : 4mm to 10mm

...more

Rubber Sheets

Rubber Sheets are used in enhancing drivability and traction between belt and pulley. Further, it also helps in the optimum functionality and is especially supportive in moist climates. We at the Continental Belting Pvt Ltd manufacture Rubber Sheets using best quality of raw material. The rubber Sheets rolls we supply comprise of both thin gauge as well as heavy gauge rubber materials. To make natural rubber more elastic, durable and resistant to various natural degrader it is combined with synthetic elastomers like: EPDM Neoprene BUNA-N (Nitrile) Silicone Thermoplastic materials Rubber Sheets manufactured by continental Belting Pvt Ltd are supplied to various cities in India and are even exported to more than 45 countries all over the world including Iran, Saudi Arabia, UAE, Qatar, Kuwait, Oman, Jordon, Mauritius, United Kingdom, Egypt, Nigeria, South Africa, Oman, Tanzania, DR Congo, Kenya, Muscat and many more. We hold expertise in offering rubber sheets to meet defined specification of – Commercial grade Food grade Industrial grade Pharmaceutical grade Other demanding specifications as required for applications like – Bridge bearing pads Industrial machinery isolation mounts

...more

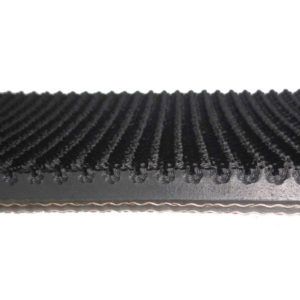

Rough Top Conveyor Belts

Rough top Conveyor Belting manufactured by Continental Belting Pvt Ltd are available in two as well as three ply construction choices that also feature cut edges as well as carcass of NN/EP fabric which comes with surface texture that aids in resisting the tendency for material to roll back down the conveyor while at transportation stage. Continental Belting Pvt Ltd is a Maharashtra based ISO9001 (2015) certified company. We are one of the most prominent manufacturer, supplier and exporter of Rough Top Conveyor Belts. All our conveyor belts are are tested as per DIN & IS1891 and are manufactured as per the standards of DIN, BS, AS, SANS, JIS, IS etc. Our Rough Top Conveyor Belts are supplied to many well know Industrial giants like exported to more than 45 countries all over the world. Rough Top Conveyor Belts are used for the application of: Transporting products like sacks, boxes and parcels. Transporting belt flight loaders, lorry loaders and other. Transportation of fragile/deformed materials as well as pack foods like papers, bags, glass boxes as well as cartons to of 35 degrees maximum. Transportations of light weight goods in either inclined or horizontal. Salient features: Available in 2 and 3 ply construction choices Top covers are made using wear-resistant rubber featuring non-slip surface Superior surface texture that resists tendency for material roll back down the conveyor Black top cover recommended for utility type incline service Special mesh like pattern that aids in generating relief effect Top cover comprises full 1/8 thick SBR Back of belt protected through durable friction surface bottom or through synthetic bare-back for slider bed applications Mollifying as well as absorbing vibrations and impact received on transported materials simultaneously also aiding in prevention of slipping

...more

Rough Top Conveyor Belt

Construction: Two or three ply construction with cut edges and carcass of NN or EP fabric. The surface texture resists the tendency for the material to roll back down the conveyor. The top cover is made of wear-resistant rubber with a non-slip surface. It has cushioning effect, mollifies and absorbs vibrations and impacts given on transported materials and simultaneously prevents slipping. Available with bottom cover or bare back for slider bed applications. Although it depends on the transported materials, transportation at inclination angles 25 ~ 30 are feasible. Application: Rough top conveyor belt is used for transporting light weight goods, such as sacks, boxes and parcels, on inclined surface at angles of maximal 35 degree. Typical Applications are for lorry loaders, belt flight loaders, etc.

...more

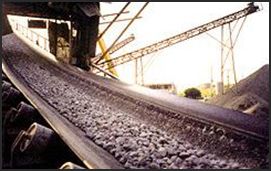

quality Rubber Conveyor Belts

Rapid industrialization has increased the need use of conveyor belts for the transportation of materials from initial raw material to finished products. Rubber conveyor belts are commonly used to convey items with irregular bottom surfaces, small items that would fall in between rollers or bags of product that would sag between rollers.It is often lightweight, durable and wears resistant. Maharashtra based Continental Belting PVT. LTD was established in 1984 and since then we have been the prominent manufacturer, supplier and exporter of Conveyor Belts. All our Rubber Conveyor Belts are ISO9001 (2015) certified and are manufactured on the standards set up by the DIN, BS, AS, SANS, JIS, IS, etc. Common industries which use these include- Table Top Mat Top Angled Roller Belting Micro Span Our Rubber Conveyor Belts are highly demanded by the all the well-established perfection demanding companies like ACC, Ultratech Cement, Steel Authority of India, Reliance Energy, Godrej and many more from all over India. Applications for this type of Rubber Conveyor Belt Belting include: Food production Pharmaceuticals Manufacturing Packaging Salient Features of Continental Belting Rubber Conveyors Belts are: High friction for inclining/declining High temperature resistant Tear, rip or cut resistant for very long working life Best material used and unique carcass built to prevent any mechanical damage Pelleted packing facility also available on customization Resistant to Mildew, Moisture, Rotting and even suitable for the application under Ozone and Ultra Violet Radiation

...more

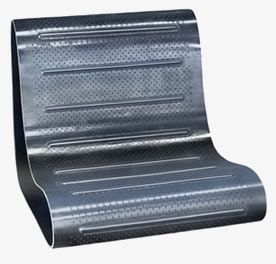

Pulley Lagging Sheets

Very helpful in improving drivability / traction, between the belt & pulley, especially helpful in moist climates. These are available in standard Diamond Profile.

Thickness : 10mm

...more

Pipe Conveyor Belts

Pipe or Tube conveyor belts are primarily used where bulk materials must be conveyed along horizontal and vertical curves in confined spaces, and/or where the environment has to be protected resp. where spillage must be avoided. The belt can negotiate tight horizontal and vertical curves. This eliminates or reduces transfer points, which is a big cost saving. Inclinations of up to 35° can be dealt with. Pipe conveyor belts protect the conveyed material from external influences like rain and wind and protect the environment by avoiding spillage of the conveyed material. Even in the bottom run, no spillage will occur, because the carry side is inside of the tube. The idler supports can be spaced farther apart, because it is self-supporting. An additional conveyor cover is not necessary. Some of the salient features of Pipe Conveyor Belts Dust and spillage free transportation Low noise emissions Inclines up to 35° Multiple feed and discharge points Simultaneous conveying of different materials in both directions Low power consumption Horizontal and vertical curves with radii to 45 metres

...more

Oil Resistant Conveyor Belts

Oil resistant belt carries parts and components coated with machine oil, heavy-oil treated coal in cooking plants and electric power generating plants, soybean draff, fish meat and other oily materials. Materials containing non-polar organic solvents and fuel. The belt compounded of oil resistant synthetic rubber has good resistance to the damaging effects encountered when conveying oil contaminated or treated materials. We can manufacture conventional OR Grade belts, as well, as High Abrasion Resistant (HAR-OR). OIL AND GREASE RESISTANT CONVEYOR BELTS ARE SUITABLE FOR: Concrete plants Recycling and mineral processing plants, Waste sorting and Compost machines Metal processing industry, Scrap recycling Timber industry and Sawmills Excreta and sewage sludge conveying Corn, rape and soilages conveying Solvent extraction plants Paper industry HOR (HEAT & OIL RESISTANT) BELTS HOR Conveyor Belting is manufactured specially for applications, where there is a combination of heat & oil exposure, in areas, such as Bitumen / Hot Mix Plants. HOR HEAT & OIL RESISTANT COVERS PROVIDES: Heat & Oil Resistance up to 180°C Superior resistance to petroleum & mineral oils Resistance to a number of acids & chemicals Resistance to swelling & delamination Totally resistant to moisture, mildew & rot

...more

heat resistant belts

Continental Belting, have developed, the specialist PyroShield range of Heat-resistant belts, with covers that resists cracking and hardening. PyroShield belting performs over the long run, retaining its flexibility despite punishing conditions and loads. Less cracking and hardening translates into longer life and reduced replacement costs. High-temperature resistance to tearing and abrasion. Load after load, PyroShield stands up to prolonged exposure. This reduced maintenance and downtime helps lower overall operating costs. PyroShield provides superior performance under extreme heat conditions. The PyroShield compounds retain their heat-resistant qualities after prolonged exposure to hot loads from (200°-300°C). APPLICATIONS Cement industry Steel and iron industry Fertilizer Chemical industry Coking plants Foundries Submerged Ash Handling Waste utilization Glass Works RANGE OF TENSILE MEMBERS / CARCASS OF PYROSHIELD BELTS Cotton Nylon EP Steel Cord Kevlar PYROSHIELD RANGE OF COVERS PyroShield 120 (HR T1 – 120 Deg C) PyroShield 150 (SHR T2 – 150 Deg C) PyroShield 200 (UHR T3 – 200 Deg C) PyroShield 250 (250 Deg C) PyroShield 550 (350 Deg C Pyroshield 250 & 350 Grades, shall have a Fibre Glass shield , just above the tensile member, which shall act as a string deterrent, against through holes caused, due to red hot material.

...more

general conveyor belt

M24 - Our range of M24 (24MPa) Conveyor Belts are abrasion resistant and highly resistant to cuts and gouges. These are mainly used in all mining industries and process industries such as cement (limestone), steel (crushed metallic ores), stone crushing industries (granite & blue metal). N17 - Our range of N17 (17Mpa) Conveyor Belts are abrasion resistant, however applications not requiring the same cut and gouge resistance as that of the M24 Grade. These conveyors belts are mainly used for conveying bauxite, asbestos, ash, chalk, cement, lime, Surface coal etc. TYPICAL APPLICATIONS : Slag conveyors Coking conveyors Broken glass / cullet Coal handling plants Cement, concrete plants Sand, gravel, stone industry Road construction machinery Timber industry and sawmills Power plants , garbage incineration plants Silica sand or materials containing silica sand Recycling, compost industry, mineral processing plants FEATURES : Anti-tear and rip resistant qualities without any equivalent in conventional fabric conveyor belts Special Steel wefts with high elongation and tensile strength properties arranged at a nominal pitch: - To break the ripping momentum; limiting any longitudinal cutting and tearing Superior carcass protection through greater impact energy distribution across the belt widt Exceptional fastener-holding ability if required Pulley system modifications not required; transversal steel/fabric weft has no influence Longer service life under heavy-duty applications Manufactured to DIN standards

...more

Food Grade Conveyor Belts

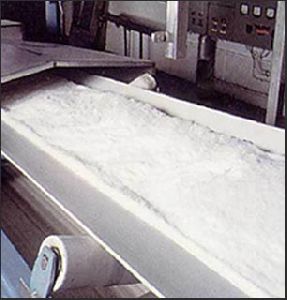

Food Grade Conveyor Belts are specifically used for the transportation of food products for their high hygienic properties. Established in 1984, Maharashtra based Continental Belting Pvt Ltd has been one of the most prominent manufacturer, supplier and exporter of best in class ISO9001 (2015) certified Food Grade conveyor belts. Working under the leadership of our CEO/Managing Director Mr Deepak Arora, a team of highly professionals and expertise in the field of 84 employee. The team at Continental Belting Pvt Ltd accomplish the feat of over 2500 meters production per day. Continental Belting Pvt Ltd Provide precisely manufactured white food grade conveyor as well as elevator belting. Our belts are available in white colour finish and do not transfer any odour as well as colour contamination to food products is handled. Application: Packaging Equipment High speed Conveyors Medical Equipment Pharmaceutical Bulk product Conveying Vacuum application Big names in the Indian market like Godrej, UHDE, Adani, Vedanta etc. prefer the Food Grade Conveyor Belts manufactured by Continental Belting Pvt Ltd. Our Conveyor Belts are even exported to the international clients from the countries like Iran, Saudi Arabia, UAE, Qatar, Kuwait, Oman, Jordon, Mauritius, and United Kingdom. Food Grade Conveyor Belts Salient features: Flex and fatigue tested before supply or exporting Customized production facility of fabricated conveyor belts Pelleted packing facility also available on customization Food grade conveyor belts are tested as per DIN & IS1891 Clean and quiet operation Belt surface do not sink which prevent water collection as well as bacterial growth High quality raw material like industrial fabric, rubber, carbon black, zinc oxide etc. for superior abrasion and chemical resistance

...more

Food Grade Conveyor Belt

OIL & GREASE RESISTANT CONVEYOR BELTS (OR GRADE) Continental Belting offers White Food Grade Conveyor & Elevator Belting manufactured, as per IS:1891 (Part IV); suited for handling food materials, directly on the belt surface. These belts are white in colour and do not transfer any odour or colour to the food products handles. Our Food Grade Belts are available in two distinct type of compositions, the first made from natural rubber, suited for non oil / acidic / reactive materials, and the second is the special synthetic rubber based compound suited for any oily or chemically active food products, such as meat, fruits & vegetables, free flowing sugar, any items with high moisture content, etc. Similar rubber cover grades are also available for elevator applications, such as grain handling, free flowing sugar, animal feed etc. Most popular applications, include operations in the sugar industry, tea industry, , grain elevators etc.

...more

Flame Fire Resistant Belt

OIL & GREASE RESISTANT CONVEYOR BELTS (OR GRADE) The product is made of Nylon carcass or EP carcass and finished through the process of calendaring, assembling, vulcanizing etc, suitable for conveying materials that require a flame resistant and static conductive belts in power, chemical, light, metallurgical and grain processing industries, under the condition of flammable or explosive environment above coal mines.

...more

fabricated conveyor belts

ontinental Belting, manufactures a wide range of rubber conveyor belts, however, if your application requirement is unique, and calls for a tailor made belt, our engineers can also create a custom product to fit your requirements. We have at our disposal, the world’s best, belt fabrication facility, with high pressure vulcanizing bay’s, punching / perforating presses, buffing & grinding machines, in-house machining and mould making. SOME TYPICAL FABRICATED BELTS FROM OUR RANGE OBMS Magnetic Separator Belts with Cleats. Tumblast Belts / Shot Blasting Belts, with Cleats and Guides. Sidewall Conveyor Belts Longitudinally Jointed Belts, up-to 3600mm width. Hot vulcanized endless belts. Perforated belts. A combination of a team of highly skilled & experienced engineers and technicians, in conjunction with the world’s best equipment, ensures a world beating fabricated conveyor belt.

...more

Chemical Resistant Conveyor Belts

Continental Belting Pvt Ltd is an ISO9001 (2015) certified and We have been providing world-class Chemical Resistant Conveyor Belts to the high profile Industrial Giants like ACC, Ultratech Cement, Steel Authority of India, Reliance Energy, Godrej, Thermax, Vedanta, UHDE, HCC, Adani, Gujarat Ambuja, JSW Steel, AIS Glass, Saint Gobain and many others. Indications for the slope angle: Approx. 30° for slightly rolling materials, such – as gravel, coal etc. Approx. 40° for sticky materials, such as wet sand, earth etc. Approx. 25° up to 35° for packages, such as sacks, bales (paper hessian) etc. All our products are manufactured as per the standards of DIN, BS, AS, SANS, JIS, IS etc. to meet the demands of our clients from various parts of the world. Our Chevron Conveyor Belts are exported to more than 45 countries including Iran, Saudi Arabia, UAE, Qatar, Kuwait, Oman, Jordon, Mauritius, United Kingdom, Egypt, Nigeria, South Africa, Oman, Tanzania, DR Congo, Kenya, Muscat and many more. Chevron Conveyor Belts Salient Features: Chevron conveying belts are tested as per DIN & IS1891 Low maintenance, high capacity Best quality of raw materials like Industrial fabric, rubber, carbon black, zinc oxide, processing oil are used to ensure the features like heat resistant, fire resistant and oil resistant Pelleted packing and Seaworthy packaging for exporting

...more

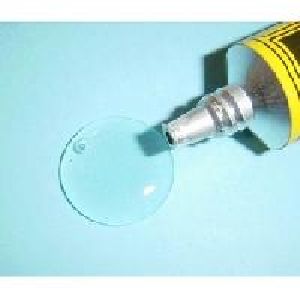

Cold Vulcanizing Solutions

old Vulcanizing Solutions also called Non Flammable Cold Vulcanizing Solution offered by Continental Belting Pvt Ltd is a black color, viscous liquid that has brushing viscosity. As a two component, room temperature curing synthetic rubber based adhesive, when catalyzed using appropriate amount of hardener, it yields high strength adhesion when bonding – Rubber to rubber Rubber to fabric Rubber to steel Rubber to PVC Fiberglass Concrete Urethane Established in 1984, Continental Belting Pvt Ltd is a Maharashtra Based an ISO9001 (2015) certified company and we have been providing Cold Vulcanizing solution for more than 30 years. Our products are qualified as per the standards set up by EN ISO 15236, DIN22131, SANS1366 and AS1333. Many high profile local Industries like ACC, Ultratech Cement, Steel Authority of India, Reliance Energy, Godrej, Thermax, Vedanta, UHDE, HCC, Adani, Gujarat Ambuja, JSW Steel, AIS Glass, Saint Gobain and many others are our satisfied regular clients. Our Cold Vulcanizing Solution are supplied to hundreds of cities all over India and are even exporter to more than 45 countries all around the world. Having our own R&D facility, we have come up with varying Cold Vulcanizing Solution for the discrete need of the range of industries. Further, these cold vulcanizing solutions are also highly popular for applications involving – Conveyor belt jointing Pulley lagging Belt repair3

...more

cold resistant belts

For the application of conveying of the substances at sub-zero temperature is a very difficult purpose. And it is made accessible by the Cold Resistant Conveying Belts manufactured by Continental Belting Pvt Ltd. When the ambient temperature falls below 0oc rubber begins to lose its elasticity, its property to resist abrasion, impact and cutting and even the rubber in the carcass begin to crack. The purpose of Cold Resistant Belts is to make conveying of materials economically feasible outdoor in the freezing areas and inside the cold storage. Since 1984 Continental Belting have been supplying its world-class Cold Resistant Conveyor Belts to our clients all over India. Our conveying belts are the exporter to more than 45 countries like Iran, Saudi Arabia, UAE, Qatar, Kuwait, Oman, Jordon, Mauritius, United Kingdom, Egypt, Nigeria, South Africa, Oman, Tanzania, DR Congo, Kenya, Muscat and many more. Cold Resistant Belts Salient Features: Available on basis of Cold-proof performance: S1 (-45oC ~ 50oC) S2 (-60oC ~ 50oC) The cover rubber can comprise combination of 3-polybutadiene Rubber (BR) and Natural Rubber (NR) for highest elasticity at lowest temperature. Available in different belt carcass including Cotton canvas, Nylon canvas or Polyester canvas. Crack and abrasion free DIN, BS, AS, SANS, JIS, IS, Standardized for quality assurance Suitable for the temperature even under -400C Conveyor belts are tested as per DIN & IS1891

...more

cold resistant belt

This belt can be supplied in cotton canvas, nylon canvas or EP canvas as carcass. Cover rubber is a blend of NR and BR, which has high elasticity, shock resistance, cold resistance etc, It can work @ -40°C. Usage: Suitable for conveying materials outdoors in freezing area, cold storage, etc.

...more

Chevron Conveyor Belts

FEATURES Excellent choice for high capacity conveying at steep angles to prevent load slip or product roll back Cleats integrally moulded with the top cover rubber preventing separation from the belt A large range of designs and patterns available Cleats with high abrasion resistance and elastic rubber compounds for flexibility Various cleat heights and widths available depending on the application requirements Unique Pattern design ensures, that, the belt has a smooth run on conventional return idlers, so no modification of the conveyor required. A smooth transition from a conventional flat belt to a Chevron belt can be implemented. Chevron belts manufactures, in all cover grades, viz. Abrasion Resistant M24, HR, OR, FR, White Hygienic, etc. SOME OF THE KEY APPLICATIONS: Wood Chips Sand and Gravel Heavy Duty Scrap Metal Minerals - Coal and Ore Materials - Fine Coal and Grains Waste and Recycling Plants Road Construction & Crushing Industries Bagged Materials Steel Pellets

...more

Chemical Resistant Conveyor Belt

OIL & GREASE RESISTANT CONVEYOR BELTS (OR GRADE) The rubber cover, which is made from chemical resistant materials, has fine anti-chemical corrosiveness and good physical property. It is specially made for those materials which would dissolve expand or corrode the belt. It is suitable for conveying material with chemical corrosiveness in chemical factory, chemical fertilizer factory, paper mills, mining industry etc.

...more

Bucket Elevators

Bucket elevators are used to elevate a variety of bulk materials form light to heavy and from fine to large lumps. Continental Belting Pvt Ltd have been manufacturing, supplying and exporting bucket elevators to its clients for more than 30 years. Continental Belting Pvt Ltd is ISO9001 (2015) certified and We have been providing world class Chemical Resistant Conveyor Belts to the high profile Industrial Giants like ACC, Ultratech Cement, Steel Authority of India, Reliance Energy, Godrej, Thermax, Vedanta, UHDE, HCC, Adani, Gujarat Ambuja, JSW Steel, AIS Glass, Saint Gobain and many others. We bucket are manufactured on the standards set up by DIN, BS, AS, SANS, JIS, IS etc. and that’s the reason Continental belting Pvt Ltd have the current turnover of 135 crores and two manufacturing industries that our Bucket elevators are highly demanded by our international clients from more than 45 countries. Bucket elevator are highly utilized in the industries like: Timber industry and saw mill Sugar refineries, salt mines, potatoes and starch factories Sand, gravel and stone industry Asphalt mixing plant Foundries Heating stations, power stations, garbage incinerating plants Bottle caps and coins Food items like cereals, coffee, nuts, pasta, frozen vegetables, snack food and pet food Ammunition, explosives and palletized chemicals Bucket Elevator Salient features: Tensile strength available from 315 N/mm up to 6300 N/mm Low elongation enabling short take-up systems Bucket elevators are tested as per DIN & IS1891 Best quality of raw materials like Industrial fabric, rubber, carbon black, zinc oxide, processing oil are used to ensure the features like heat resistant, fire resistant and oil resistant Pelleted packing and Seaworthy packaging for exporting

...more

Conveyor belts

Be first to Rate

Rate ThisOpening Hours