Magnetic Drum Separator

Get Price Quote

1 Pieces (MOQ)

‘Trimurti’ Permanent Drum Type Magnetic Separator is the most useful nonelectric separator for separating tramp iron from nonmagnetic material processed in bulk quantity for the purity of end products, recovery of metals having a commercial value, and protection of processing plant and machinery. These are widely used in all processing industries for the separation of iron contamination from minerals, chemicals, food, flour, plastics, grains, sand, cement, fertilizers, abrasives, glass slag, ores, rock, and many other products. WORKING PRINCIPLE & MAGNETIC SYSTEM The Permanent Magnetic Drum consists of a stationary permanent magnetic assembly having uniform and everlasting magnetic field across the entire width of the drum, which is effective over approximately half the drum circumference. Drum shell made of non magnetic stainless steel revolves around the magnetic field. As the material fed evenly from the chute falls over the drum, powerful magnetic field attracts and holds ferrous particles to the revolving shell. As the revolving shell carries the iron particles through the stationary magnetic field the nonmagnetic material falls freely from the shell while ferrous particles are firmly held until carried beyond divider and out of the magnetic field. The strength of the permanent magnetic drum is guaranteed to be greater than the corresponding electromagnetic drum. The Permanent Magnets used are everlasting magnets and their strength does not diminish during normal use. Note: We reserve the right to make alteration in the machine from time to time as required.

Chevron Conveyor Belts

Get Price Quote

We frequently keep a check on the storage space to ensure that it is well-maintained by the experts. We have installed the latest machines and leading technologies to save products from spoiling. We have carved a dignified position in the market owing to our on-time and safe delivery of the orders. Applications: Recycling, compost, mineral processing industries Silica, sand or materials containing silica Slag, Cooking, Broken Glass/Cullet Coal handling plants Cement, concrete plants Sand, gravel and stone industry Road construction machinery Timber industry and saw mills

Best Deals from Conveyor Components

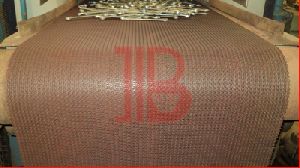

Compound Balance Weave Conveyor Belt

Get Price Quote

The mesh of compound balance weave conveyor belts are very closed, so this belts are used in those application which include carring of very small parts, such as nuts bolts, screws, nails etc.

Compound Balance Weave Conveyor Belt

Get Price Quote

The mesh of compound balance weave conveyor belts are very closed, so these belts are used in those application which include carring of very small parts, such as nuts bolts, screws, nails etc. Compound weave conveyor belt supplies extremely close and flat mesh. This is made of stainless steel and high carbon steel. They all have excellent high temperature resistance performance and high tensile strength. All these metals ensure the Compound weave conveyor belt to be a strong, durable and high lifespan product. It is also known as Cord Weave Belt. The structure of Compound weave conveyor belt is similar to the balanced weave conveyor belt, which has multiple spirals and cross rods per pitch. The compound weave conveyor belt has closer mesh than the balanced conveyor belt. The closer mesh makes compound weave conveyor belt a high density and high strength surfaceFeatures of Compound Weave Conveyor Belt :a) Small open areaThe compound weave conveyor belt has little open area, which is suitable to conveyor the small items.b) High tensile strength The compound weave conveyor belt has multiple spirals and cross rods on each pitch, so it can supply higher tensile strength than other types of conveyor belt.c) High temperature resistanceThe compound weave conveyor belt is made of high quality materials, including stainless steel and nickel alloy steel, which have excellent temperature resistance performance.d) Durable and long service life The unique structure and high quality material can ensure the long service life of compound conveyor belt.e) Baffles Different types of baffles can be added at the both side and center of conveyor belt for sorting and conveying products. Applications of compound weave conveyor belt:The compound weave conveyor belt with little open area is popular in the food, electric, mechanical and other industries. It can be used to convey the following products:• Baking biscuit. • Nuts. • Bolts. • Cookie. • Particles.

Wire Mesh Conveyor Belts

Get Price Quote

Wire mesh conveyor belts that has been flattend to provide a flatter surface that creates a smooth carring surface for small unstable parts.

Conveyor Belt

Get Price Quote

highly resistant to cuts and gouges. These are used frequently in themining industries, process industries such as Cement, Crushed ore steeland metal, stone crushing industries etc.Kiran™ range of N17 (17 MPa) conveyor belts are abrasion resistant aswell though not requiring the same cut and gouges resistance as that ofthe M24 grade. These conveyor belts are mainly used for conveyingbauxite, asbestos, ash, chalk, cement, lime, surface coal etc. Applications:• Recycling, compost, mineral processing industries• Silica, sand or materials containing silica• Slag, Cooking, Broken Glass/Cullet• Coal handling plants• Cement, concrete plants• Sand, gravel and stone industry• Road construction machineries• Timber industry and saw millsConveyor Belt Range:

Sling Neon PU Belt

Get Price Quote

Packing Conveyor Belts

Get Price Quote

Pharmaceuticals. Beverages. Dairy Industry Cosmetics Beverage Industry SALIENT FEATURES : Movement direction: Left to right. Width*: 9”/ 12”. Height*: 32” to 36”. Belt type*: PVC/ Endless. Input specifications: single phase. Speed: As per customer requirement. MOC: Complete S.S. 304 structure

Conveyor Belt Wire

Get Price Quote

Conveyor Belts wires are high carbon wires, which are bright annealed and then drawn.

Weave Conveyor Belts

Get Price Quote

The mesh of compound balance weave conveyor belts are very closed, so this belts are used in those application which include carring of very small parts, such as nuts bolts, screws, nails etc.

Conveyor Belt Cleaning Brush

100 - 10,000 Per Piece

100 Piece (MOQ)

Conveyor Belt Cleaning Brush

1,200 Per Piece

10 Piece (MOQ)

polyester lashing belts

5 - 22 Per Meter

1000 Meter (MOQ)

Conveyor Chain

Get Price Quote

1. Silverline manufacture high quality tested chains required along with cranes, depending on customers requirement : a. Chain slings with Hooks b. Chain slings with Shakle c. Chain loopsAvailable with various lengths and capacities.2. Conveyors Chains / Transmission Chains / Slate Chain We produce conveyors chains as per customer specific requirements. We can design and supply any capacity conveyor system and chains required for material handling.

Conveyor Belt Wire

Get Price Quote

Conveyor Belts wires are high carbon wires, which are bright annealed and then drawn. Systematic manufactures conveyor belt wire of the highest quality standards.

Conveyor Belt Cleaning Brush

Get Price Quote

200 Piece (MOQ)

Poly V Belt

Get Price Quote

Conveyor belts

Get Price Quote

We are pioneers among Carbon Steel Conveyor Belt Manufacturers in India. We use high quality S.S, High Carbon, Spring Steel, G.I. for producing best Metal Conveyor Belts. Our Stainless Steel Conveyor Belts ensure easy & smooth transportation of raw materials, and finished goods from one place to another within factory premises. We provide Metal Conveyor Belts in any size as per customers� specifications. Industries Used in : Bottling PlantsCement IndustryBaking IndustryDehydration PlantCeramic Industries

Coal Feeders

Get Price Quote

We are offering Coal Feeders

magnetic separation machine

Get Price Quote

Features of Magnetic Separation Machine- High intensity. High garden, high power rare earth magnets Available with flanges to suit square and round chutes Available with angle deflectors above and between the tubes for heavy contamination Direct access to magnets in chute Easily installed and extremely easy to clean