Screw Feeders

2,000 Per Set

bottle conveyer screw

Screw Feeders

80,000 Per Piece

Best Deals from Conveyor Feeder

Weigh Feeder

Get Price Quote

Weigh Feeder

Get Price Quote

Principle of OperationA weigh belt feeder enables a continuous, controlled product flow. The bulk material is transported over a weighing section, placed in the feeder frame. The federate is calculated and the speed of the belt adjusted to maintain a constant feed rate.If the purpose of the belt feeder is to register the throughput only, the speed of the belt remains constant and the mass flow and cumulative weight is registered.ApplicationsWeigh Feeders are widely used in Coal feeding Steel plant Cement plant Chemicals & fertilizers Open mines Tobacco industry

Micro Pulveriser Without Screw Feeder

Get Price Quote

Micro Pulveriser Without Screw Feeder is generally used for grinding dry or wet material of medium hardness like foodstuff, dye products, pharmaceutical products, fibrous products, cattle feed dry fish etc. Micro Pulveriser Without Screw Feeder is known for providing specified and smooth blending of the product. Material grinded through this machine does not lose its original color, taste, fragrance etc. Feeding can be done either by screw feeding or direct feeding. It consists of rotor shaft assembly, beaters, liners, and retaining screen. Attributes Compact, rugged design No auxiliaries Dust free operation Quick and easy cleaning Water cooling system Air balloon Principle SF Micro Pulveriser is a rugged, high capacity, low maintenance, economical unit designed to produce specified grinding and smooth blending results. Grinding is done under cool atmospheric air, thus retaining the original colour, taste and fragrance of the ground material. The powder obtained is as good as hand ground powder. Frigmaires Micro Pulveriser not only grinds the feed material but also blends and disperses the same in a single dustless operation. The maximum mesh obtainable will be approx.250 Mesh. Principle of Pulverizing Micro Pulverizer consists of a rotor assembly fitted with hammers (beaters) & is generally operated at high speeds. The grinding action in all the pulverizers is due to the impact between rapidly moving hammers (beaters) & the particle itself. The energy of the moving hammers is dissipated into the particles being ground by virtue of their inertia, thus causing the particle size reduction. Rotor Shaft Assembly : The rotor shaft is made of suitable quality steel & is assembled with beater assembly & sufficient number of bearings to withstand the loads caused by high - speed revolutions & the impact of beaters & the particles.Beaters : These are a set of hammers revolving at high velocity inside the grinding chamber. The beaters are surface hardened . Special types of beaters are provided for heat sensitive materials.Liner : The multiple deflectors or the serrations provide multiple breakers for still further reduction of the particle size by virtue of impact between the rapidly moving particles & the multiple deflectors. The liner enhances the ultra � fine pulverizing because the particles break down by the force of impact against the breakers. These are specially designed to minimize heat due to the impact of beaters on the particles being pulverized.Retaining Screen : The screens are replaceable & are available in various mesh sizes. Their function is to hold the material in the grinding chamber until the particles are ground to the required degree of fineness. The particle size is not accomplished by the screens. Feeding Arrangement The material to be ground is uniformly fed to the grinding chamber by gravity with the help of feed valve. This type of arrangement is extremely successful for materials, which cannot be conveyed into the grinding chamber due to their light � weight or due to their size. Gravity feeding can be used to pulverize materials like sugar, salt or carbon, as these types of material are extremely easy to grind. It gives the same order of fineness as the screw-feeding unit does & completely eliminates the screw feeding assembly. Features Compact, Rugged Design : Each part is precisely engineered from quality materials. The micro pulveriser grinds, blends & disperses in a single dustless operation. Rugged, accurate & carefully designed, it assures increased capacity & longer machine life.No Auxiliaries : The finished product in a pulverizer is a result accomplished without the aid of cost consuming auxiliaries such as fans, air separators, classifiers, cyclones etc.Dust Free Operation : The accurately machined surfaces ensures effective sealing against dust, leakage while the machine is still in operation.Quick & Easy Cleaning : Cleaning is greatly simplified due to the absence of auxiliaries. The simplicity of design also makes all parts easily accessible for fast cleaning & inspection. Easily cleaned & inspected, it saves labour & reduces the maintenance costs.Water Cooling System : A water-cooling system is provided for cool grinding.Air Balloon : Air balloon is provided which eliminates the back pressure and cools warm air circulating in the grinding chamber.

Automatic Screw Dispenser

13,999 Per Piece

1 Piece (MOQ)

Smart Weigh Belt Feeder

Get Price Quote

weigh belt feeders for gravimetric feeding at higher feed rates or where low headroom is a problem. Especially at high feed rates, a weigh belt feeder offers lower initial cost than a loss-in-weight feeder with equal throughput.

Weigh Belt Feeder

Get Price Quote

LIW feeder is a system to extract the granulated or powdered solids at constant rate from feed hopper; weight measured decrease in hopper content actuates further opening of the discharge chute to compensate for flow loss. The proposed system includes weigh hopper, Loadcells, screw conveyor with motor and microprocessor based control unit. This system is mostly used in chemical, fertilizer and plastics industries.

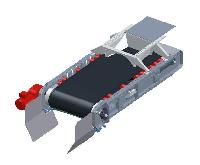

Belt Feeders

Get Price Quote

These short belt conveyors are employed to extract material under dump hoppers or under material bins. Belt feeder design needs to consider all specific requirements determined by the material being moved, as well as capacity and geometry. Our feeders combine a reinforced belt, robust heavy-duty idlers and frames with liners and chute work. Our diverse product range covers standardized belt feeders, as well as specific heavy-duty feeders with large handling capacities exceeding 8,800 th. Depending on site andor client specific requirements, we are able to preassemble machines in our workshop and ship in large pieces to site.

Weigh Belt Feeder

Get Price Quote

Micro Pulveriser Without Screw Feeder

Get Price Quote

Suitable for grinding of wet or dry material of medium hardness upto 4 on mohs scale such as food products, dyestuff, pharmaceutical products, cattle feed dry fish, fibrous products etc. PRINCIPLE: Frigmaries Micro Pulveriser is a rugged, high capacity, low maintenance, economical unit designed to produce specified grinding and smooth blending results. Grinding is done under cool atmospheric air, thus retaining the original colour, taste and fragrance of the ground material. The powder obtained is as good as hand ground powder. Frigmaires Micro Pulveriser not only grinds the feed material but also blends and disperses the same in a single dustless operation. The maximum mesh obtainable will be approx.250 Mesh.

SCREW FEEDER

Get Price Quote

When it comes to Oscillating Feeder, there is hardly any alternative to Abhishek Engineering Pvt. Ltd. we supply very high quality high speed oscillating feeder which cannot be availed through anywhere else. We are well known as an oscillating feeder manufacturer and exporter from India.

Aggregate Feeding Belt Conveyors

50,000 Per Piece

Volumetric Vibratory Feeder

45,000 Per unit

SCREW FEEDER

Get Price Quote

It comprises of a spiral flights fixed on a rod enclose in a pipe driven by a geared drive unit. The speed can be varied by Variable Frequency Drive. Material is received from feed hopper at the inlet at one end and discharged into the subsequent at the other end.

Twin Screw Feeder

184,000 Per

Weigh Feeder

Get Price Quote

We are offering weigh feeder applications in cement, steel, fertliser, chemical, pharmaceutical, food, refractories, ceramic, zinc, alum industries. Capacity 10 kghour to 500 tonneshour accuracy 0.5 % or better depending upon material characteristics. Micro controller based systems ensures highest possible reliability. Large size ( 8 mm) backlit lcd display for parameter values. Access to program mode through pass word. 4-20 ma signal proportional to flow rate is available. Rs232485 serial communication.

Coal Feeders

Get Price Quote

We are offering Coal Feeders

Weigh Feeder

Get Price Quote

We are a top-notch Manufacturer, Exporter and Supplier of Weigh Feeder from Maharashtra, India. We are backed by a team of sincere personnel who makes use of non-corrosive and durable metal for its production so as to lift up its quality and performance. It is designed strictly keeping in mind the industry specified norms. You can get the Weigh Feeder from us at the cost-effective prices. Salient Features :Design : Very Sturdy and Rugged Frame Design Quick Belt change mechanism ensures very low down time. Designed for capacities from 1 to 2000 TPH Unique Dual Load cell design for accurate weighing Feed control inputs from Driving as well as Driven pulleys to ensure Precise feed rate. Accuracy as high as + 0.5% on the set point Electronics Our Electronic controller ensures trouble free interface with the plants processes and control system. Specially developed Software offers seamless integration with PLC or PC Service Support of the customer does not end once the equipment is sold. It is the beginning. With after-sales support being the cornerstone of our business philosophy, we offer prompt and efficient after sales service.

Screw Type Weigh Feeder

202,000 Per Units

SCREW FEEDING

Get Price Quote

Powered by electric motor the material to be ground is fed to the grinding chambers in a uniform way by screw feeders. Feed screws are made in single & multiple types designed to convey the material from feed hopper to grinding chamber & at the same time act as a pre-crusher for reducing large soft mass of material to suitable size for the micro pulverizers. Screw feeding can be provided with variable speed arrangement.

Weigh Feeder

Get Price Quote

Weigh Feeder, Belt Weigher, Material Handling Equipment, SCREW FEEDER

volumetric feeder

Get Price Quote

volumetric feeder, Measuring Cups, Pharmaceutical Product, Volumetric Pipette

Screw Feeders

Get Price Quote

Screw Feeders, Conveyor belts, FRP Fiber Door, Fire Rated Steel Doors

Belt Feeders

Get Price Quote

Belt Feeders, Belt Conveyor Systems, Bucket Elevators, Chain Conveyors

Weigh Feeder

Get Price Quote

Weigh Feeder, Check Weigher, Tank Weighing System

Screw Feeders

Get Price Quote

Screw Feeders, Jar Capping Machine, Capping Machines, Screw Conveyor System

Screw Feeders

Get Price Quote

Screw Feeders, Shaft Bearings, Flexible Coupling, Cast Iron Bearing Housings

Aggregate Feeding Belt Conveyors

Get Price Quote

Aggregate Feeding Belt Conveyors, Adjustable Wrench, Ball Bearings, Blade

Thayer Weigh Belt Feeders

Get Price Quote

Thayer Weigh Belt Feeders, Ash Handling Dry Fog System