Electric Industrial Oven

20,000 - 200,000 Per Units

3000 Units (MOQ)

Pizza Oven

Get Price Quote

Best Deals from Conveyors

Vacuum Ovens

Get Price Quote

Name of the unit vacuum oven-(rectangular) technical specification double walled in construction. Inner made of thick gauge stainless steel plate with argon welding. ( ss 304 ) outer body made of heavy gauge mild steel with powder coat finish. High grade glass wool insulation. Nichrome made heating element embedded with ceramic beads. Silicon gasket for tightening and to minimize the heat loss. Full length toughened glass door with wing nuts. Double hand shut – off valve for vacuuming & purging. Dial type vacuum gauge for viewing of vacuum pressure. Solid state digital temp. Controller & p.t – 100 sensor. Optional safety controller facility. Perforated stainless steel trays. , no. Of trays . 4

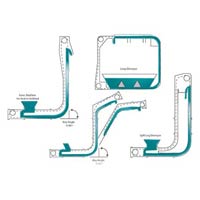

Redler Conveyor

Get Price Quote

The Redler Conveyor, offered by us, allows bulk materials to be moved smoothly and economically. Materials are handled gently, creating a fluid conveyor system which can move horizontally, vertically and around bends. There are many benefits of using Redler Conveyor systems, including Automatic feeding at any point on the conveyor system Feeding is uniform and completely accurate Materials are handled as solid columns There are no internal disturbances or pressure on materials Loads can be discharged at any opening Redler Conveyor systems are specifically designed to aid in material handling This allows for reliable conveyor systems which yield excellent results

Conveyor Weighing System

191,250 - 225,000 Per piece

1 Piece (MOQ)

slat chain

Get Price Quote

50 Piece (MOQ)

Canola Oil

Get Price Quote

100 Litre (MOQ)

Laboratory Drying Oven

Get Price Quote

1 Piece (MOQ)

Lab Drying Oven “TEMPO” make lab drying TI ‐ 126 series ovens with forced air draft provided by means of blower fitted at the bottom of the oven. There is no re‐circulation of air. Standard Models Inside SS 304 with mirror polish & outside mild steel powder coated. GMP Models Inside SS 316 with mirror polish & outside stainless steel 304 with the dull buff finish. Construction Ovens are made of double walled construction. The unit is insulated with 3” thick high grade glass wool insulation. The single door is fitted on heavy duty hinges. The unit is provided user friendly adjustable stainless steel rod trays. Technical Specification Controlling System Microprocessors based autotune PID temperature controller with a dual display of set value & process value for precise control of temperature with PT 100 sensor is used for temperature. Air Circulation Forced air draft is provided by means of blower fitted at the bottom of the oven (there is no re‐circulation of air). Heating System Heating element made from the best quality Kanthal wire are used on refractory supports. Features Additional safety thermostat to cut off heater supply in case temperature of overshoot. The single door fitted on heavy hinges. Specially designed stainless steel rod trays to ensure uniform temperature distribution. Optional Features CFR 21 part 11 compliance software for data logger Data logger Data scanner complete with sensor Safety digital temperature controller Timer

Plastic Conveyor Belt

500 Per Meter

50 Meter (MOQ)

Belt Conveyor

Get Price Quote

We provide our clients a comprehensive collection of Belt Conveyors that is widely used for carrying material from one end to another. Available in varied lengths and widths, these can be customized as per the specifications detailed by the clients. In addition to this, our conveyors are used in pharmaceutical, agriculture and various allied industries to transfer material. All these conveyors are widely acclaimed due to their easy installation, sturdy construction and low maintenance features.our rang for belt conveyors size form 100mm to 1800mm wide belt for industeries.

Attachment Chains

735 Per Meter

30.5 Meter (MOQ)

Electric Curing Oven

Get Price Quote

Very effective for high production rate. Cure in uniform rate. Convection/Direct/Indirect/Infrared Heating System High efficient heat transfer and energy utilization. Heats by line of sight. High thermal efficiency Fine control and proper uniformity Aesthetic finishing Thermal loss is prevented by filling rock wool (Insulation) in space between the outer body & Inner chamber. Customized sizes designed to meet customers’ requirements

Powder Transfer Systems

Get Price Quote

KERONE along with its dedicated team of process equipments machinery manufacturing and design team and technically equipped manufacturing facilities has helped in succeeding in providing the high quality and technically advanced process equipments for the various need of the Powder Transfer Systems. The PTS Powder Transfer System is an extraordinarily efficient and dependable technique of conveying and dispensing dry and wet powders and granules. Main Components of Powder Transfer System: A vacuum conveying system utilizing Roots Blower, Modular construction equipment. Jet Air Wand with Air regulating Damper. Jet Air Wand fitted with stainless steel wire mesh to stop foreign particles entry in to process. Entire transfer through electro polished pipe with curvilinear bends and isolating valves both manual and pneumatically actuated. Suitable filters pleated 5 micron in the product unloading chamber, pulse jet type for inside cleaning.

Poly V Belt

Get Price Quote

We offer poly v belt made from superior quality material which ensure that they work continuously for long durations. Highly reliable, these belts are available as per the desired specifics.

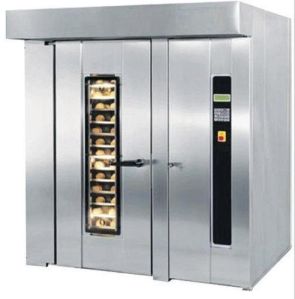

Rotary Rack Oven

2,500,000 Per Piece

Convection Oven

22,998 Per

1 Piece (MOQ)

Debris Bucket

3,500 Per Piece

Pizza Oven

Get Price Quote

Description This range of pizza ovens is manufactured utilizing SS 202 & 304 in complete adherence with the industry laid norms. In addition to this, the offered range is available with a power load of 3.5 kw and it comes in six standard sizes.In order to append and respond to the assorted requirements of the esteemed clients, we are able to dispatch a superior range of Pizza Oven. High performance Silent operation Dimensional Accuracy Safe to use

Vacuum Powder Transfer System

Get Price Quote

EMCO VTS technology provides innovative solutions for automated transfer, dosing and packaging of powders by means of vacuum and pressure. VTS with its unique filtration concept makes the only vacuum dense-phase system that functions at optimum levels when handing ultra-fine, sticky and adhesive powders. VTS* (Vacuum Transfer System) Dust Free Filling and discharging Packaging Dosing No product retention No particle damage Easy to clean

Vacuum Ovens

49,000 - 125,000 Per 1Nos

1 Piece (MOQ)

CAP ORIENTING AND FEEDING ELEVATOR

150,000 - 350,000 Per piece

1 Piece (MOQ)

Six Cell Ageing Oven with Data Logger

200,000 - 300,000 Per Piece

1 Piece (MOQ)

Digital Temp. (PID) Controlled Six Cell AGeing Oven with Digital Hour Meter, Rotameter for AIr flow measurement. Inbuilt Air pump for each cell. ALl Cells are different. Different temperature can set in each Cell . Range: 50 to 200Degree Centigrade. With Data Logger.

Micro Pulveriser Without Screw Feeder

Get Price Quote

Micro Pulveriser Without Screw Feeder is generally used for grinding dry or wet material of medium hardness like foodstuff, dye products, pharmaceutical products, fibrous products, cattle feed dry fish etc. Micro Pulveriser Without Screw Feeder is known for providing specified and smooth blending of the product. Material grinded through this machine does not lose its original color, taste, fragrance etc. Feeding can be done either by screw feeding or direct feeding. It consists of rotor shaft assembly, beaters, liners, and retaining screen. Attributes Compact, rugged design No auxiliaries Dust free operation Quick and easy cleaning Water cooling system Air balloon Principle SF Micro Pulveriser is a rugged, high capacity, low maintenance, economical unit designed to produce specified grinding and smooth blending results. Grinding is done under cool atmospheric air, thus retaining the original colour, taste and fragrance of the ground material. The powder obtained is as good as hand ground powder. Frigmaires Micro Pulveriser not only grinds the feed material but also blends and disperses the same in a single dustless operation. The maximum mesh obtainable will be approx.250 Mesh. Principle of Pulverizing Micro Pulverizer consists of a rotor assembly fitted with hammers (beaters) & is generally operated at high speeds. The grinding action in all the pulverizers is due to the impact between rapidly moving hammers (beaters) & the particle itself. The energy of the moving hammers is dissipated into the particles being ground by virtue of their inertia, thus causing the particle size reduction. Rotor Shaft Assembly : The rotor shaft is made of suitable quality steel & is assembled with beater assembly & sufficient number of bearings to withstand the loads caused by high - speed revolutions & the impact of beaters & the particles.Beaters : These are a set of hammers revolving at high velocity inside the grinding chamber. The beaters are surface hardened . Special types of beaters are provided for heat sensitive materials.Liner : The multiple deflectors or the serrations provide multiple breakers for still further reduction of the particle size by virtue of impact between the rapidly moving particles & the multiple deflectors. The liner enhances the ultra � fine pulverizing because the particles break down by the force of impact against the breakers. These are specially designed to minimize heat due to the impact of beaters on the particles being pulverized.Retaining Screen : The screens are replaceable & are available in various mesh sizes. Their function is to hold the material in the grinding chamber until the particles are ground to the required degree of fineness. The particle size is not accomplished by the screens. Feeding Arrangement The material to be ground is uniformly fed to the grinding chamber by gravity with the help of feed valve. This type of arrangement is extremely successful for materials, which cannot be conveyed into the grinding chamber due to their light � weight or due to their size. Gravity feeding can be used to pulverize materials like sugar, salt or carbon, as these types of material are extremely easy to grind. It gives the same order of fineness as the screw-feeding unit does & completely eliminates the screw feeding assembly. Features Compact, Rugged Design : Each part is precisely engineered from quality materials. The micro pulveriser grinds, blends & disperses in a single dustless operation. Rugged, accurate & carefully designed, it assures increased capacity & longer machine life.No Auxiliaries : The finished product in a pulverizer is a result accomplished without the aid of cost consuming auxiliaries such as fans, air separators, classifiers, cyclones etc.Dust Free Operation : The accurately machined surfaces ensures effective sealing against dust, leakage while the machine is still in operation.Quick & Easy Cleaning : Cleaning is greatly simplified due to the absence of auxiliaries. The simplicity of design also makes all parts easily accessible for fast cleaning & inspection. Easily cleaned & inspected, it saves labour & reduces the maintenance costs.Water Cooling System : A water-cooling system is provided for cool grinding.Air Balloon : Air balloon is provided which eliminates the back pressure and cools warm air circulating in the grinding chamber.

Curing Oven

Get Price Quote

CURING OVEN 4 mtr X 2 mtrs X 2.5 mtrs fully automatic inside ss 304 outside ms with steam generator ( 20,000 panels) 3 mtr X 2 mtrs X 1.8 mtrs fully automatic inside ss 304 outside ms with steam generator ( 10,000 panels) Our Curing Ovens are designed and manufactured with precision & the highest quality in the industry. Each oven is customized to fit the customer’s requirement for productivity and safety. Alpha Solutions offer a variety of Curing oven arrangements to fit both space and production requirements. Whether you need small oven or large, Alpha Solutions can build the oven to suit your needs or you can choose from one of the many standard designs. Expandability : It start with a lower capacity and expand in 2500 panels increments up to 30000 panels. Options : There are various options available • Steam Generator• Spray Nozzles/Humidifies• High Pressure Vaporizer• Electrically Heating System• Gas Fired Heating System• Process Heat Recovery System• Advanced temperature and humidity• Monitoring and controlling system Serviceability : New diagnostics assist in trouble-shooting problems to minimize downtime and maximize quality Versatility : Our experience in building custom ovens for all industries can be put to the test if you need that special oven configuration designed to fit your needs. Our Customer knows that A S India INC. ovens can change right along with their needs. Alpha Solution’s Plate Curing Oven Features : • PLC / Microprocessor-based digital temperature controls.• Temperature recorders as standard equipment on conveyor models• Non-overloading circulation fans• Adjustable air orifices• High Temperature light fixture inside oven• Bottom to top airflow forced and natural convection heating• Access doors for inspection and maintenance• 4-inch insulated oven panel construction with steel frame• experienced service staff and large supply of spare parts. Steam Generators High pressure steam generators are essential for many industrial processes that require heating media temperatures at very high level. We are engaged in offering a wide range of Fully automatic products. These are most suitable for continuous supply of ultra-dry steam and are highly fuel efficient. What is Curing ? • The modern Trend is towards use of lead sub oxide with 30% metallic lead• The presence of metallic lead has brought significant changes in the methods of handling plates immediately after being pasted. • The need for such changes arise from the peculiar behavior of pulverized lead in the presence of air and moisture. In a perfectly dry condition, lead does not oxidize and this is equally true in case of abundance of water. • The latter condition is beneficial in operations until the actual pasting of plates. • Once the paste is applied to the grids, the residual moisture, the atmospheric humidity and ambient temperature all become significant. • The problem then is to control these three factors so that oxidation to litharge occurs and the free lead content is reduced from 25 %- 30% to less than 3% Why is curing process important ? • Proper curing improves strength of the dried plates.• It also result in proper bonding of interface between the grid and the paste .• Improper curing results in scaling or shedding of active material during formation process or service lifeWhy is curing a special process? • In battery manufacturing, curing is the special process where the result of the output cannot be verified by subsequent monitoring or measurement. As a consequence deficiencies become apparent only after the product is in use or services has been delivered. • To control the process, the following measures are required: • Defined criteria for review and approval of the process• Approval of equipment and qualification of personnel• Use of specific methods and procedure• Requirement of records• Re – validation

Conveyor belts

Get Price Quote

We are engaged in offering a qualitative range of Conveyor Belts, which comprises two or more pulleys along with a continuous loop of material. For moving the belt and the material forward on the belt, one or both of the pulleys are powered. Furthermore, all these Conveyor Belts are checked from time to time by our experienced quality analysts to ensure that these are defect free. Also, these Conveyor Belts are appreciated for their resistance to heat and shock, longevity, and sturdy construction.

conveyorised oven

Get Price Quote

We offer flat belt conveyorised oven, which is an electrically heated conveyor oven. These consist of various zones in where in same temperature can be provided in the zones along the path of the belt. Control panels are provide on each zone and also a common control panel can be provided as per the client's requirement Fansblowers are incorporated in each zone for air circulation and uniform temperature Products are places on the belt on loading side of the oven & unloaded from the other side

Magnetic Chip Conveyors

Get Price Quote

We are offering a range of Magnetic Chip Conveyors that is widely used by the clients for handling metal chips. These magnetic conveyors are totally enclosed can be lowered in the sump and chips are collected outside in a drum or trolley. Fabricated with quality raw material to stand constant wear, these conveyors have high intensity magnets moving inside which bring all the ferrous impurities.

16 Channel Combiner

2,200 Per Piece

10 Piece (MOQ)

LIGHT DUTY PLATE MAGNETS

Get Price Quote

Magnetic Plates are important industrial iron separators that are used for the separation of fine ferrous materials and tramp iron from many types of free flowing and pneumatically conveyed material like corn, sugar, flour, gravel, plastic and others granular materials. Can be installed in chutes or suspended above conveyor belts and pulleys for low volume, lightweight andor slow-moving applications. Also available with powerful rare earth magnets.