Pre Heating Infrared Conveyor

100,000 Per Piece

Vacuum Oven

105,000 Per Piece

1 Piece(s) (MOQ)

Best Deals from Conveyors

P U Incline Belt Conveyor

Get Price Quote

Taking a heights of successful and reputation in industry we are manufacturing and supplying a wide assortment of PU Belt Conveyor. This is best improved technology based PU Belt Conveyor much easier to use and install, incredible higher utility with durability.

Industrial Conveyor

200,000 Per Piece

Conveyor Type Shot Blasting Machine

Get Price Quote

Packing Conveyor Belts

Get Price Quote

The packing conveyor belt is a table like structure. It has stain less steel table top. There is a moving endless sandwich belt in the centre. The tabletop is fixed to the table with S.S. square pipe. It is supported by the adjustable bolts.

Vacuum Oven Round Standard Model

Get Price Quote

Double walled in construction. Heat treated toughened glass window provides clear viewing of samples. Maximum vacuum upto 760mm of mercury column. Silicon gasket and positive door latch assures tight seal at all vacuum levels. A vacuum type stop cock & vacuum gauge are fitted on the top. Installed with Digital Temperature Indicating Controller with a suitable sensor for precise temperature control. Unit works on 230 V AC, 50 Hz supply. Standard Model – HIPL- 027 Outer body made of Mild Steel [ 20 swg. ] duly powder coated and cylindrically shaped Inner Chamber made of heavy gauge Stainless Steel LM-304 grade Digital Temperature Indicating Controller with a suitable sensor for precise temperature control. Tray type Shelves are made of Stainless Steel Optional : Microprocessor based AUTO TUNING PID Digital Temperature Indicating Controller for precise Temperature control with BUILTIN Digital Timer in lieu of standard Controller (FOR STANDARD MODELS ONLY) Microprocessor based PROGRAMMABLE PID Controller cum Indicator with Printer Interface to connect Dot Matrix Printer. Print interval programme can print Date, Time & Temperature with print interval settable between 1 to 99 minutes [ without Printer ] Same as above but with PC software & connectivity

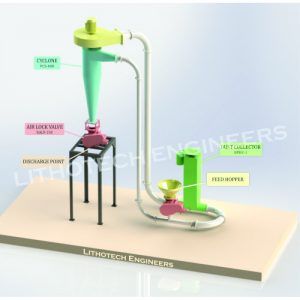

Pneumatic Conveying Systems

Get Price Quote

The Pneumatic Conveying system will convey the powder from the Pulveriser into the collection bin. It will separate the air from the material thereby preventing dusting. The air will exit through the Dust Collector. The constant circulation of fresh Air into the system ensures powder to remain cool.

Crusher Conveyor Belt

Get Price Quote

Thermodrive Belt Conveyor

Get Price Quote

Hot Air Ovens

Get Price Quote

Stech Engineers Hot Air Ovens are designed for laboratory purpose. These ovens are highly accurate in temperature stability and circulating Hot Air throughout the chamber with the help of an Air Blower.

Vacuum Oven

Get Price Quote

Round Vacuum Oven

Get Price Quote

Thermolab vacuum ovens are an ideal choice for quick drying without posing risk to the samples. The Vacuum oven has a robust design with a toughened glass viewing window and a shatter- resistant safety screen. The interior is made of corrosion-resistant stainless steel which is easy for maintenance. Thermolab Vacuum ovens operate within a temperature range of 50 0C to 200 0C which is suitable for a wide range of applications.

Automatic Conveyor Polishing Buffing Machine

Get Price Quote

Special Features & Benefits of Stainless Steel Automatic Polishing Machine : For Polishing / Buffing, Brushing & ‘Mush Buffing’ of numerous types of components with variety of Buffing Heads. ROHIT fabricates a system for individual needs. These versatile Heads can take on the Large and most intricate Shapes. The ‘Mush Buffing’ technique uses broad wheels at low RPM, eliminating the cost of shaping the Buffing Wheels for each different part. Production rate from 10,000 to 25,000 Pcs. per Shift in some instances. Applications of Stainless Steel Automatic Polishing Machine : Flat Components in any Metal, Plastic, Fiber.

enrober conveyor belt

600 - 1,500 Per meter

100 Square Meter (MOQ)

Rod network belts, also known as enrober conveyor belts or flat flex conveyor belts, feature specially designed "Z-bend" joints in the wire mesh. They are perfect for transporting light and medium weight products in food processing industries. Features : High proportion of open area up to 86% makes the belt efficient in cooling, drying, heating applications. Road network belts are normally driven by sprockets positively without need for complicated tracking mechanisms. With smallest diameter end rolls and drive rolls, the rod network belts provide stable conveying of delicate products. Various sizes with different openness to suit different applications providing superb strength and min contact surface between the products and the belts. Generally, the more the joints cross the width, the stronger the belt Low belt mass than balanced weave belts for lower power consumption, faster processing and more product throughput. The high open structure without hidden crevices makes the belt easy to clean and maintain which result in considerable cost saving. Belt Edge Rod network conveyor belts can be manufactured with three types of bending end: single loop edge, double loop edge and C-shaped loop edge. Details : Quality spring steel AISI 1060; stainless steel wire 302, K2930 or custom others. 67.5% to 86% 0.035" to 0.11" as your request. 1/8" to 3/4" or custom others. 3" to 14' or custom width as your request.

Roller and Conveyor

Get Price Quote

Slat Conveyors

Get Price Quote

1 Piece(s) (MOQ)

Material Handling is the movement, storage, control and protection of materials, goods and products throughout the process of manufacturing and distribution. Material handling systems are a fundamental part of the manufacturing system since it interconnects the different processes.

Pu Conveyor Belts

150 - 500 Per MeterCM

PVC / PU conveyor belts are the most commonly used belts for conveying application. These belts are made from high strength polyester carcass laminated with PVC / PU coatings - having Plain or textured finish. Top Surface: Coated with PVC / PU or Non Coated. Tension Member: Fabric of high strength polyester mono filament Bottom Layer: Bare Fabric or coated with PVC / PU Properties: Virtually Stretchless Dimensionally Stable Flexible Low Noise Easy Maintenance Easy to Handle & Economical to Use PVC / PU belts can be used in horizontal, incline or even curved conveying applications. They are available in various thickness, colours, chemical resistance and with various surface & bottom patterns. These belts can also be fitted with Sidewalls, Cleats (partitions), tracking guides, etc. PVC / PU belts can be supplied as Endless belt using hot vulcanization or with mechanical fasteners. All our cleats and sidewalls are welded using the most modern Ultrasonic welding system which ensures clean and strong fixing of Cleats & Sidewall. Due to its versatile nature PVC / PU conveyors are used in the basic to the most demanding applications in almost all types of industries like material handling, Food, Fitness, Ceramic & Tile, Textile, Engineering, Airports, Automobiles, Electronics, Chemical, Packaging, Paper & Board, Distribution & logistics.

Motorized Conveyor System

80,000 Per unit

1 unit (MOQ)

Conveyor belts

Get Price Quote

Over the years, our company has a cemented its position in Mumbai(India) and is determined to become a trusted provider in other markets as well. We stringently follow automated warehousing system that helps us in meeting the safe storage requirements. Thus, we ensure zero damage to the products till the final dispatch.

Polyester School Uniform Belt

50 Per piece

50 piece (MOQ)

Pneumetic Conveyor System

Get Price Quote

We bring forth for our clients, a quality range of pneumatic conveying systems and equipment that is made using advanced technology. Widely used in food, pharmaceutical, chemical and packaging industries, these systems are offered as complete turnkey systems as per the requirements of our clients. Following are some of the details of these systems: Dust free Made using stainless or mild steel Dense phase vacuum systems for fragile and pre-mixed product Sophisticated controls Positive pressure lean phase systems Specialized powder handling for non free flowing products Abrasion resistant systems High accuracy multi material weighers The P-Series filtered receivers for use with powders and friable materials in sanitary applications

Pizza Oven

Get Price Quote

5 Pieces (MOQ)

Weigh Feeder

Get Price Quote

Principle of OperationA weigh belt feeder enables a continuous, controlled product flow. The bulk material is transported over a weighing section, placed in the feeder frame. The federate is calculated and the speed of the belt adjusted to maintain a constant feed rate.If the purpose of the belt feeder is to register the throughput only, the speed of the belt remains constant and the mass flow and cumulative weight is registered.ApplicationsWeigh Feeders are widely used in Coal feeding Steel plant Cement plant Chemicals & fertilizers Open mines Tobacco industry

Conveyor Belt Cleaning Brushes

850 - 3,500 Per Piece

Conveyor belt cleaning brush.we manufacturer flat, round shape brush for conveyor belt cleaning brush.we also do customisation as per customer requirements

Roller Conveyor System

Get Price Quote

We are a reputed Manufacturer and Supplier of Roller Conveyor System that are fabricated by using high grade raw material. The Roller Conveyor System is durable, high on performance and needs low maintenance. Roller Conveyor Systems are widely used in heavy duty application and can bear sturdy construction. Attributes DurableRobust steel baseLow operational cost High in functionalityAvailable in customized length, width & height

Industrial Conveyors

40,000 Per Piece

hydro pneumatic systems

Get Price Quote

he series Z Hydro-Pneumatic Systems have been developed for applications where two or more Cylinders have to be operated from a single Reservoir-Intensifier Power unit. They are also useful for applications requiring a large travel under load (large Power Stroke) and for applications where the length of our standard ‘N’ series Hydro-Pneumatic Press systems cannot be accommodated.

industrial electric ovens

Get Price Quote

With their maximum working temperature of 260280300 °C and forced air circulation, the ovens achieve very good temperature uniformity. They can be used for various applications such as e.g. drying, sterilizing or warm storing. The stainless steel interior chamber is easy to clean and resistant to rust. Ovens for high-forced volume thermal convection applications. These ovens generally provide uniform temperatures throughout. Process applications for laboratory ovens can be for annealing, die-bond curing, drying, Polyimide baking, sterilizing, and other industrial laboratory functions.

Automatic Screw Dispenser

13,999 Per Piece

1 Piece (MOQ)