Telecom Cooling System

Get Price Quote

Liebert industrial infrastructure & Telecom Enclosures Liebert ICS, Industrial Cooling Series, 140-210kW Liebert InteleCool2, Shelter Cooling System, 5.25-17.5kW

Chilled Water System

Get Price Quote

Industrial Refrigeration offers Chilled Water System for food, pharma, & chemical industries. IRPL manufactures Water Cooled Screw Chillers incorporating reliable screw compressors from Bitzer (Germany) and Frascold (Italy). These chillers are fully Microprocessor based suitable for process cooling applications from (+) 20˚C up to (-) 40˚C. For lower temperatures of up to (-) 50C look into Brine Chillers. These screw chillers are offered with up to 2 Nos. Screw compressors in one machine but having separate and individual refrigeration circuits. These chillers are world class, manufactured in an ISO 9001, certified factory with an option of using CFC free refrigerants R-407C & R-134a complete with in-built Process pump and stainless steel chilled water expansion tank. These chillers are also rated for an ambient of up to (+) 50˚C and cooling tower water temperature up to (+) 37˚C at the inlet of the condenser. The various operating voltages of these chillers are: a) 380 400 Volt AC 50 HZ b) 460 Volt AC 50 HZ c) 380 Volt AC 60 HZ d) 460 Volt AC 60 HZ.

Best Deals from Cooling Systems

Chilled Water System

Get Price Quote

Industrial Refrigeration offers Chilled Water System for food, pharma, & chemical industries. IRPL manufactures Water Cooled Screw Chillers incorporating reliable screw compressors from Bitzer (Germany) and Frascold (Italy). These chillers are fully Microprocessor based suitable for process cooling applications from (+) 20˚C up to (-) 40˚C. For lower temperatures of up to (-) 50C look into Brine Chillers. These screw chillers are offered with up to 2 Nos. screw compressors in one machine but having separate and individual refrigeration circuits. These chillers are world class, manufactured in an ISO 9001, certified factory with an option of using CFC free refrigerants R-407C & R-134a complete with in-built Process pump and stainless steel chilled water expansion tank. These chillers are also rated for an ambient of up to (+) 50˚C and cooling tower water temperature up to (+) 37˚C at the inlet of the condenser. The various operating voltages of these chillers are: a) 380 / 400 Volt AC / 50 HZ b) 460 Volt AC / 50 HZ c) 380 Volt AC / 60 HZ d) 460 Volt AC / 60 HZ. Features:- RELATED ALL TYPE CHILLER The glycol chillers, brine chillers, air cooled brine chillers, water cooled brine chillers and liquefiers offered by IRPL are tailor made to suit customer requirement. IRPL offers these low temperature Glycol / Brine up to an operating temperature of (-)50˚C for which compressors can be single stage open type / double stage open type / double stage semi hermetic / single stage screw depending on the size and the temperature requirement of the customer. For very low temperature application even Cascade systems are used for quick cooling. The material of construction is selected carefully depending on the application temperature and special alloys steel is used for ultra lower temperature application. These chillers can be air-cooled or water-cooled depending on the customer requirement. These chillers are rated for an ambient of (+) 480C and various operating voltages which are: a) 380 / 400 Volt AC / 50 HZ b) 460 Volt AC / 50 HZ c) 380 Volt AC / 60 HZ d) 460 Volt AC / 60 HZ Applications:- Food processing industry Accelerating mould of plastic. Extending the life-span of mechanical components. Electronic industry and ultrasonic cleaning industry. Electroplating industry cooling to enhance precision of electroplating. Food processing industry cooling to enhance the quality of food. Advantages:- Water temperature can be set at random from 0.5 degrees to 20 degrees. Intelligence control system can automatically adjust the load increasing and decreasing of the compressor to maintain outlet temperature in certain degree based on water temperature. The flow of water varies from 1.5m3/h to 24m3/h, which can meet different needs. Containerized structural design, which can be transported to places where refrigeration is needed.

Cooling Air Knife Systems

Get Price Quote

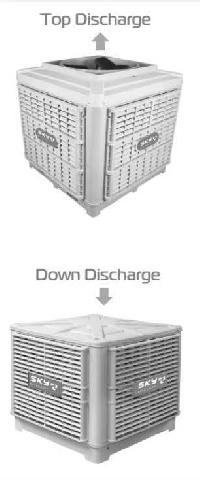

SKY Air Cooling System

Get Price Quote

We offer Sky Air Cooling System. Evaporative cooling is a physical phenomenon in which evaporation of a liquid, typically into surrounding air, cools an object or a liquid in contact with it. Latent heat describes the amount of heat that is needed to evaporate the liquid; this heat comes from the liquid itself and the surrounding gas and surfaces. When considering water evaporating into air, the wet-bulb temperature, as compared to the air’s dry-bulb temperature, is a measure of the potential for evaporative cooling. The greater the difference between the two temperatures, the better the evaporative cooling effects. When the temperatures are the same, no net evaporation of water in air occurs, thus there is no cooling effect.

Cooling Tower Distribution System

Get Price Quote

10 Piece(s) (MOQ)

We Sgct Manufacturing All Types Of Distribution System Like Hot Dip Galvinse, Pvc,Frp ,PVC Lateral Pipe & And We Design As Per Water Capacity With Lateral Pipe With This We Offer To Our Client Flow Control Valve.

Mini Cooling System

Get Price Quote

The solid state cooling system is based on peltier effect & can be used for applications such as viscosity bath & other small cooling application These are basically miniature Thermoelectric Solid State Systems, designed on peltier effect. In many situations, need of analysis at subambient temperature arises. The lab chemist has to use either an elaborate and bulky compressor based cooling system or use ice. Both have their own disadvantages. These Systems are simple, sturdy & occupy very small bench space. No compressor no noise, no vibrations. No Ice, no mess. All SolidState design, no moving parts, virtually maintenance free. These are suitable to carry out Titration at subambient or at elevated temperatures, to maintain Cell Holder Temperature, viscosity measurement, to cool vials & test tubes etc. Model MCS - 150 For titrations at sub ambient or at elevated temperatures : In this case the titration beaker ( 55mm Dia) is inserted in the block which is kept at desired temp. Application : Titrations for diazotisation , SAP value and pH Stat

Fluid-water cooling systems FWKS

Get Price Quote

The FWKS is a compact fluid-water cooling system for cooling and lubrication circuits with a plastic tank with circulation pump, a plate heat exchanger and additional accessories. This system is primarily used as a temperature-controlled intermediate circuit. In this way the contamination and corrosion in the coolant circuits which could arise as a result of directi cooling with poor water quality is prevented. Function: The pump conveys the cooled operating fluid from the tank through the component that is to be cooled. Once there, it absorbs the heat. It then flows back to the plate heat exchanger, where it is returned to a cooler temperature by the cooling water. Technical data: Cooling capacity: up to 250 kW (depending on the limiting conditions) Flow rate: up to 300 lmin Tank content: up to 110 l Cooling medium: water

Product Cooling Systems

Get Price Quote

We are leading manufacturer and supplier of product cooling systems like air cooling system or direct contact cooling and indirect contact cooling.

Radiation Cooling

Get Price Quote

portable cooling systems

Get Price Quote

We are the leading manufacturers and trader of Coolant Management Systems and our product is made of good quality. A complete laboratory service for analysis of coolant samples and technical advice is available as an integral part of the CMS fluid control system. The CMS concept is based on both direct supply of fluids and equipment or a range of modular management services, from basic control to complete management.

Single Fluid Heating Cooling System

Get Price Quote

Traditional Heating & Cooling Systems Active Pharmaceutical Ingredient (API) manufacturing involves batch reaction, work-up, distillation, crystallization, hydrogenation, layer separation, filtration and drying as unit processes. Again, batch reaction involves heating and cooling stages ranging from -50°C to +250°C. Traditionally, this was being done with multiple utilities such as chilled brine, chilled water, cooling water, hot water, low pressure steam, high pressure steam, thermic fluid etc. Limitations Different heat transfer fluids (HTFs) may require separate coils, heating and cooling jacket zones or external heat exchangers. Time consuming changeover of HTFs and associated risks of human error. Cross contamination of HTFs. Multiple utilities can corrode the reactor jacket. Condensate recovery is not feasible. Inefficient management of HTFs leading to inaccurate temperature control. Process parameter deviations adversely affect product quality. Complicated mechanical design, and Increases capital/maintenance costs.

Cooling System

Get Price Quote

Kilburn has designed, manufactured & successfully commissioned a new drying cum cooling system for sugar crystals from cane sugar. The system ensures integrity of the crystal structure & enhances brightness of sugar. This is achieved by the lower moisture content & virtual elimination of fine sugar crystals.

chilled beams

3,300 Per unit

We are the main supplier of this product.

engine cooling systems

Get Price Quote

Enginemates has long experience in designing and manufacturing Engine Cooling System for Diesel generating sets. The cooling package is complete and consists of either Engine Jacket Water (EJW) , Low Temperature Aftercooler (LTA) and fan assembly OR Engine Jacket Water (EJW) , Charge Air Cooler (CAC) and Fan assembly. Fuel Coolers are also part of these cooling package in most modern engines. We manufacture engine cooling systems for small KVA ratings to about 500 KVA. Key features:- Custom Built for requirements Steady Performance Easy Installation Long Life Compact Applications Small to Medium KVA rating Diesel generating sets

Warehouse Cooling Systems

Get Price Quote

Thermospyphon Cooling System

Get Price Quote

Hot and Cold Stages

Get Price Quote

Instec was founded over two decades ago by a group of pioneering liquid crystal researchers, therefore our microscope heating and cooling stage systems are designed specifically with liquid crystal applications in mind. Over the years, Instec has continued its effort to respond to the needs of the experimental community and has developed a series of thermal stages to suit different application needs. Our heating and cooling stages offer many features which are unique in the marketplace, such as dual heating with variable sample chamber height, large viewing aperture, and easy electrical access to the sample. Instec hot and cold stages have been used in a variety of research fields, including:

Ceiling Cooling System

Get Price Quote

Chilled Shower Bath System

50,000 Per Piece