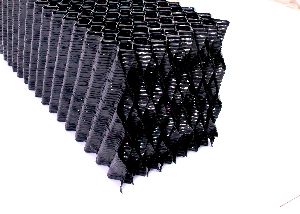

Cooling Tower Fills

110 - 500 Per piece

10 piece (MOQ)

We are supplying cooling tower fills and other spare material as per client requirement

V Splash Bar Fills

Get Price Quote

10 Piece(s) (MOQ)

Cooling Tower Fill Is The Main Heat Transfer Area Available For Heat Transfer From Hot Water To Cold Air. The Splash Fills Disintegrates The Hot Water From The Vertical Direction And It Splits The Water To Pass Through Next Level Of Splash Bars.. Fills Are Normally Made Of Pvc, Wood.

Best Deals from Cooling Tower Fills

Cooling Tower ABS Fills

320 Per Piece

100 Piece(s) (MOQ)

PVC Cooling Tower Fills

Get Price Quote

Splash Fill

Get Price Quote

Splash Fill dispatched by us in the markets is made using high quality raw materials. High strength, low power consumption, durability and longer working life characterize the range of Splash Fill that we manufacture. We specialize in providing them in small or bulk quantities as per the requirements of the clients. Splash Fill is obtainable at market leading rates.

Cooling Tower PVC Fills

110 Per Cubic Feet

200 Cubic Feet (MOQ)

abs fills

Get Price Quote

These are best quality ABS Fills to resist water with high temperatures in cooling tower systems, they have excellent formability and superior stiffness critical to high degree media applications. Apart from this remarkable quality and sturdy structure increase the demand of our offered range in the market. Materials have roughened surfaces to enhance glueing adhesion. Features : Rugged construction Easy installation Rust resistant Specification â�� UV Stabilized ABS(Acrylonitrile butadiene styrene) for high temperature applications with a thickness of 0.2mm and can resist water flow temperature upto 80°celsius.

Cooling Tower Fills

Get Price Quote

1. Cooling Tower Application Counterflow 2. Flute Height 12 MM 3. Longitudinal Pitch 38 MM 4. Spiral Angle 28 Degree 5. Standard Sheet Size (L X W) 600 MM X 300 MM 6. Max Recco Fill Sheet Size (L X W) 1,800 MM X 600 MM 7. Surface area per unit Volume 250 sq m cu m OR 76 sq ft cu ft 8. Max continuous operating temp 55 Degree Cent 131 Deg Farenheit 9. Standard fill sheet thickness 0.22 MM OR 0.008” 10. Standard Weight of the fill pack 800 GMs 11. Fills Colour Blue 12. Edge Folding Double

Film Fills for Cooling Towers

Get Price Quote

Film Fills are the most efficient filling media available for cooling towers. The usage of film fills – in both counterflow and crossflow cooling towers allows relatively smaller sized towers to cool an equivalent amount of water compared to cooling towers using splash fills. This results in the saving of not only capital costs for a new tower but also reduces operational costs on account of lower height and hence lower pumping costs. Film Fills work on the principle of offering heat exchange by spreading the falling water droplets into a thin molecular film where the air can effectively contact the entire surface of the water film to carry away heat and mass. Advantages Minimum resistance to air flow Good distribution of water leads to turbulent mixing of air and water to maximize heat transfer. Reduced fill height and greater cooling capacity results in lower power consumption. Erosion and rotting resistant and long lasting (10-12 years of service time in good quality water) Self-supporting, high strength and self-extinguishing characteristics Resistance to weather exposure (fungii/oxidation) ; Nearly impervious to chemical degradation by Alkali, acid, grease, fats, oils and biological attack Easy to glue at site, reduces transportation cost.

Film Fills for Cooling Towers

Get Price Quote

Film Fills are the most efficient filling media available for cooling towers. The usage of film fills – in both counterflow and crossflow cooling towers allows relatively smaller sized towers to cool an equivalent amount of water compared to cooling towers using splash fills. This results in the saving of not only capital costs for a new tower but also reduces operational costs on account of lower height and hence lower pumping costs. Film Fills work on the principle of offering heat exchange by spreading the falling water droplets into a thin molecular film where the air can effectively contact the entire surface of the water film to carry away heat and mass. Advantages Minimum resistance to air flow Good distribution of water leads to turbulent mixing of air and water to maximize heat transfer. Reduced fill height and greater cooling capacity results in lower power consumption. Erosion and rotting resistant and long lasting (10-12 years of service time in good quality water) Self-supporting, high strength and self-extinguishing characteristics Resistance to weather exposure (fungii/oxidation) ; Nearly impervious to chemical degradation by Alkali, acid, grease, fats, oils and biological attack Easy to glue at site, reduces transportation cost.

Cooling Tower PVC Fills

Get Price Quote

Clients can avail from us the wide assortment of Cooling Tower PVC Fills, at very reasonable prices. The Cooling Tower PVC Fills offered by us, are efficiently capable of facilitating the larger water surface area in contact with the maximum air supply, for a longer duration. The Cooling Tower PVC, that we offer, is globally sought after for the excellent performance and long service life. Select Cooling Tower PVC Fills As Per The Following : Various heatsCooling tower typesFlow ratesWater qualityHorse power combinations Why Our Cooling Tower PVC Fills? High tensile strengthMade as per the industry set normsDependableCost-efficient price

PVC Cooling Tower Fills

Get Price Quote

PVC Cooling Tower Fills, cooling tower fan balancing

cooling tower fill

Get Price Quote

cooling tower fill, Portable cooling unit, cooling towers spare parts

PVC Cooling Tower Fills

Get Price Quote

PVC Cooling Tower Fills, Dry Cooling Tower, Cross Flow Cooling Tower

Cooling Tower Fills

Get Price Quote

Industrial Gas Cylinders, Compressor Wheel, Compressor For Oxygen Plant

cooling tower fill

Get Price Quote

cooling tower fill, cooling towers spare parts, Induced Draft Cooling Tower