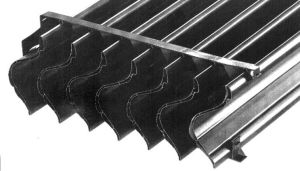

Double Wall Drift Eliminators

Get Price Quote

We are offering a wide range of Double Wall Drift Eliminators. Drife146, double wall construction is a state-of-the-art drift eliminator that offers best efficiency and performance, is made of specially formulated UV stabilized rigid PVC having superior physical properties. These Double Wall Drift Eliminators are designed removing entrained partides from exhaust air stream efficiently, with minimum pressure drop, thereby reducing the fan energy requirement when the air passes through the drift eliminator. The drifel146 double wall drift eliminator provides dimensional stability and durability, with rugged design & structural integrity for long service usage. These Double Wall Drift Eliminators are superior in practically removing tower drift in an energy efficient way. These can be pressure washed, if necessary, without any damage and can be easily assembled at site allowing span up to 1830 mm. Further, no gluing, no special tools or skilled labor is required. These drift droplets carried in the air stream, when forced to make the three changes in direction in each blade, create centrifugal forces on the drift droplets, forcing them to be captured by impaction and direct interception. Sinusoidal passage forms are widely acknowledged as the most effective design. The flow of carryover water droplets is interrupted as a result of each direction change in these zones. These water droplets are captured on the sidewalls of drife146, they form a film of water that come down the wall via gravity to the drainage channels. This reduces the opportunity for reintrainment. Moreover, no voids or discontinuities exist in the eliminator section. Drife146 double wall drift eliminators have found wide acceptance in the industry and can give a drift loss of less than 0.001% of the circulating water rate, for all droplets larger than 65 microns. We have in-house testing machine to test these products as per ASTM, BIS, DIN, etc. The purpose of testing is to evaluate products to measure the results against the requirements, document the differences and also in order to help in resolving the differences.

Cooling Nipples

20 Per Piece

500 Piece (MOQ)

Best Deals from Cooling Tower Parts

Cooling Tower Fills

Get Price Quote

1. Cooling Tower Application Counterflow 2. Flute Height 12 MM 3. Longitudinal Pitch 38 MM 4. Spiral Angle 28 Degree 5. Standard Sheet Size (L X W) 600 MM X 300 MM 6. Max Recco Fill Sheet Size (L X W) 1,800 MM X 600 MM 7. Surface area per unit Volume 250 sq m cu m OR 76 sq ft cu ft 8. Max continuous operating temp 55 Degree Cent 131 Deg Farenheit 9. Standard fill sheet thickness 0.22 MM OR 0.008” 10. Standard Weight of the fill pack 800 GMs 11. Fills Colour Blue 12. Edge Folding Double

Cooling Tower Grid Fills

Get Price Quote

10 Piece(s) (MOQ)

Optic Grid Fills Is A Direct Replacement Splash Fill For Use In Counter Flow Cooling Tower Where Dirty Water Is A Concern .Optic Grid Splash Fills Is Maximizing Number Of Water Drop Lets & Highest Surface Of Water Are Passing Through Air .This Fills Are Made Of Polypropylene,(Pp) It Is Resistant To Attack From Acids, Alkalis, Muddy Water , Ash, Etc.

Cooling Nipples

20 Per Piece

Pvc Drift Eliminator

Get Price Quote

Drift eliminators are used to capture water droplets in the air stream that otherwise would be lost to the atmosphere. Entrapping these droplets is important for not only conserving water as a resource but also to prevent cooling tower water from contaminating the area peripheral to the cooling tower. The cooling tower industry uses drift rate to compare drift eliminator performance, a relationship that correlates droplet capture efficiency to the water circulation rate in a tower. COOLDECK’s drift eliminators are specifically designed to achieve maximum drift removal efficiency in both crossflow and counterflow tower applications with various product options available to minimize pressure drop, drift loss, cost, or a combination of all three.

Cooling Tower Spare Parts

Get Price Quote

Cooltech Cooling Equipments uses high quality cooling tower spares like Rotary Sprinklers, PVC Fills, Fan Assembly and FRP Casings for Cooling towers. Cooltech is also a supplier of Cooling tower spares contact 9322274824 to order any of these spares which are available in different sizes for different capacity cooling towers.

Cooling Tower Parts

Get Price Quote

Cooling Tower Parts, Cooling Tower, Chilling Plants

Perforated V-Bar

Get Price Quote

Perforated V-Bar is the most extensively used product in the industry. COOLDECK can supply the stainless steel or FRP coated wire mesh as well as the other components that are needed for the entire splash bar system. The water droplets spread over the solid surface and perforated holes of the splash bar. The flowing water is held on the holes due to surface tension and forms a thin film. The water film formed over these rectangular holes has very low surface tension at its corners and thus a tendency to rupture frequently. During this process of rupturing the water film is broken into small globules, thus providing maximum heat transfer. Features and Advantages Diamond shaped perforations are recommended as they offer the ideal surface tension to rupture the water droplets. The top edge of the V-bar is reinforced so as it offer bending and load strength.. Ensuring a minimum thickness of 1.5mm and a maximum distance of 600mm between adjacent bars will help reduce the possibilities of sagging. Compact locking of the V-Bar on the grid using a V-Bar clip (as depicted in the picture) will also ensure a sturdy fill structure. The overhang of the V-bar of the last grid should be restricted to 150mm. Algae resistant and Fire retardant COOLDECK's V-BAR clip design provides secure locking capabilities preventing wear on both the wire hanger and the fill. The tab locks provided on the V-bar prevent it from slipping once locked into place.

cooling tower drive shafts

Get Price Quote

drive shafts in hot dip galvanized steel and stainless steel grades. The couplings are normally of cast iron. Cast stainless steel Grades are available upon request. The drive shafts are suitable for fans ranging from 8’ to 33’diameters . The drive shafts are tublar floating types and have flexible flanged couplings at both gear and motor ends , to compensate for any misalignment . The flexible elements are neoprene bonded metals. The length of the drive shafts are as per the cooling tower requirements. The drive shafts are dynamically balanced confirming to ISO 1946 Grade 6 prior to dispatch.

aluminum fins

Get Price Quote

aluminum fins, Patch Fitting, Aluminum Doors

Cooling Tower Spares

Get Price Quote

Cooling Tower Spares, Aluminium Impeller, frp blades, hub, Sprinkler

aluminum fin

Get Price Quote

aluminum fin, F.T.L Caps & Lamp Caps, aluminum gasket, aluminum vial seals