Cooling Tunnels

Get Price Quote

All thanks to our smart inventory management owing to which safe and quick deliveries are furnished by us. Clients can stay assured for the products that we offer, as they will remain damage free. For this, we make use of premium packaging material for wrapping them. Features : Best suited for high output manufacturing plants Quick installation Long lasting performance.

Pet Bottle Cooling Tunnel

Get Price Quote

Hot Juice filled Pet Bottles are cooled down while Carbonated Drink bottles, are warmed using Cooling Tunnel or Warmer Unit. Combined Machine can be used for initial project set where both the products are being done and can be separated later by adding warmer unit. Bottles travel through machine to achieve increase or decrease in temp. Features: Corrosion abrasion High tensile strength Excellent purification Other Details: The Cooling Tunnel is design for hot filling line to cooling down the bottle from high temperature to ambient temperature Cooling tunnel designed with different temperature zone to bring down the temperature step by step to achieve the best cooling effect Also provides possibility for sensitive beverage use as pasteurization tunnel Capacity: 6000 BPH - 48,000 BPH Specifications: Condition: New Place of Origin: Mumbai, Maharashtra (INDIA) Brand Name: Aguapuro Voltage: 380 V Power (W): 11.5 kW Usage: plastic bottles Weight: 4500 kg Dimension (L*W*H): 10800*1900*2100 Certification: ISO9001:2008/HACCP/GMP Warranty: 12 months After-sales Service Provided: YES Construction material:: SS316L/SS304 Control type: automatic Processing Types: Juice Processing: processing line

Best Deals from Cooling Tunnels

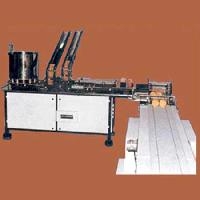

Chocolate Cooling Tunnels

Get Price Quote

MSSS Fabricated enrober with pre and post bottoming arrangement, chocolate flow pan, shaker detailing rod with separate drive, a curtain of air-flow, jacketed tank with its independent temper water pumping system. Chocolate pump to feed chocolate from the main tank to flow pan. Main control panel centrally located having all controls including those of conveyors with variable speed motors.

Cooling Tunnels

Get Price Quote

Cooling tunnel is used to cool jelly products All Contact parts SS 316 and non contact parts SS 304. Basic structure with Mild steel with SS 304 cladding. Cooling Tunnel design is focused on the need for fast changeovers.

cooling tunnel

Get Price Quote

Cooling tunnels feature: Independent and multi-layer structure. Making full use of space, shorten 2/3 of conveying length High cooling efficiency, energy conservation: Reducing 50% working time of refrigeration unit High quality oriented materials: Smooth and reliable transportation, no noise 2 Segment Cooling TunnelFor decorated materials and colour sprayed products

cooling tunnel

Get Price Quote

cooling tunnel

1,200,000 Per Units

cooling tunnel

Get Price Quote

Hot filled bottles from the filler will be transferred into the Cooling Tunnel which will have three zone cooling system. Each zone will be maintained at a higher temperature than preceding zones, with the final zone having the lowest temperature which is close to the room temperature. To hold the temperature in first zone, there will be a steam injector system as well as fresh water delivery system. Both controlled by a digital temperature controller set on heat-cool principle. The function of this temperature controller will be if temperature is above a pre-set level, cold water will be taken in and temperature lowered. The Spray system is made from stainless steel perforated sheets such that entire width and length is covered by water spray. To prevent water from collecting on the bottles an air knife is placed at the outfeed of the machine, which will blow away the excess water.From the Cooling Tunnel when fresh water is injected into the tank , there will be over flow of the hot water which gets collected in 1200 liter tank built into the tunnel and will be circulated by Plate Heat Exchanger and will bring down the temperature to 35 0 c. Tunnel will be connected through circulating pump like filling piping water system.We use MCC make plastic chain and matching sprocket in the cooling tunnel. The main body is made entirely from Stainless Steel.

cooling tunnel

Get Price Quote

cooling tunnel, Bottle Warmer, steam shrink tunnel, Conveyor

Hot fill Bottle Cooling Tunnel

Get Price Quote

Hot fill Bottle Cooling Tunnel, Air Conveyor and Airveyor

Vibratory Cooling Tunnel

Get Price Quote

Vibratory Cooling Tunnel, Pouches, toffee wrappers, Deck Oven

Cooling Tunnels

Get Price Quote

Cooling Tunnels, enrober machine, case packer machine