Electro Hydraulic Thruster

Get Price Quote

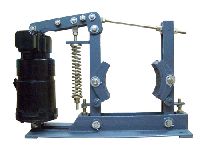

We are among the renowned Hydraulic Thruster Brake Exporters and Manufacturers from India. Our Electro Hydraulic Thruster has high level of strength and is highly durable. The Crane Electro-Hydraulic Thruster produced by us is available in various shapes and sizes. They are available in different models and are capable of delivering thrusts ranging from 10 Kg to 295 Kg. We ensure that are thrusters are duly checked before they are dispatched to the clients. Features Self-contained unit, which does not require any external components or accessoriesSelf-contained unit, which does not require any external components or accessoriesPermissible up to 720 operationsSmooth and Free linear motionLower power inputs and generated less heatFull constant thrust at all positions of working stroke

Electro Hydraulic Thruster

Get Price Quote

Introduction In addition to wide range of applications in mechanical engineering applications, the thruster operated drum brakes are mainly used in material lifting and handling equipment, mainly because their 'Fial-to-safety' designs ensure safety to men and machines in the event of over failure. With the advancement in electricl drives and electronics, the drives have pushed the mechanical systems to high level of operations and demanding safer and reliable braking loads moving at much higher speeds than earlier. Continuous developments in product improvisation and assured quality checks, the thrusters offer compact, reliable yet economical solutions to most of the industrial applications.. Assembly and Function The two main sub-assemblies of the hydraulic thruster, the electric motor and the hydraulic unit are co-axially assembled form the working unit. In the switched off state (de-energised) the piston is at its lowest position due to external load (as brake spring of the drum brake), and the brake is applied. When energized, the electric motor drives the pump and delivers working fluid under the piston axially in the guided path, and delivers thrust or force required to operate the attached devise (like thruster brake) via the piston rod and the eye-lug attached to it. The working stroke can be steplessly controlled by external load. The thruster is designed for long trouble free service. The motor windings are designed to meet contingencies. The bearings are adequately sized. Features: Gentle Application and release of brake without jerks and shocks Compact unit Constant magnitude Self aligned movement Low power consumption Minimum maintainance Easy mounting and dismounting

Best Deals from Crane Brake

Electro Magnetic Thruster Brakes

Get Price Quote

For infallible operation of machinery, modern methods are necessary, any machines which requires its motion to be controlled, whether it is lifting Crane, Hoist, Wintch or Mining Haulage today employs an Electro Magnetic Brake, enabling the operator not only to control the motion but also to hold the load at any desired point without danger of falling, merely by release of the starting handle. Electro Magnetic Brake is adequate equipment for safer operations of machinery. Electro Magnetic Brakes are used when a load must be stopped rapidly to prevent it from roatating.These brakes are used in Paper Mills, Drives of certain Textile Machines, Sugar Mill Machinery, Rubber Mixing Mills. Assembly and Function : The shoes are of cast iron and other components are of fabricated steel. The lever is hinged on main arm, which is connected to the side arm through a tie rod, and is stress by pre-loaded compression spring. The compression of spring can be adjust to set the braking torque to desired value. The brake liner of selected quality material is reveted to the shoes by aluminium rivets. A.C. solenoid with laminated magnetic sheet steel houses a copper magnetizing coil which is impregnated with class F materials. The plunger which is connected to the lever, is drawn into the coil, when it is energised with A.C. source. This loads the spring and releases the brakes shoes from brake drum. When the supply is cut off, the plunger is pull out of the coil, and spring force clamp the brake shoes on the brake drum and the brake is applied. A.C. Drum Brakes are suitable for single phase A.C. supply up to 440V and are available for drum diameters of 100 mm to 380 mm and braking torques up to 69 kg-m. Features : - Compact design - Fail Safe - Reliable in operation - Clean work environment - Braking Torque can be easily adjusted - Requires less maintenance

hydraulic thruster brake

Get Price Quote

Electro-Hydraulic Thruster is a device which develops linear thrust (or force) required to operate the desired mechanism. The Thrusters are widely used to actuate thruster shoe brakes, commonly used in material handling equipments. Thrusters are available in various models.

Flame Proof Thruster

Get Price Quote

Thruster Brake

Get Price Quote

Thruster Brake, Dsl Shrouded Bus Bar, Indicating LED Lamp, Shrouded Bus Bar

mill duty thruster breaks

Get Price Quote

mill duty thruster breaks, electro hydraulic thrustors

Electro Magnetic Brake AC And DC

Get Price Quote

Electro Magnetic Brake AC And DC, FG Compact Rotary Limit Switch

Electro Hydraulic Thruster

Get Price Quote

Electro Hydraulic Thruster, Magnetic Clutch