Bimetal Bandsaw Blades

Get Price Quote

Boxer 8% cobalt General PurposeAs the name suggest these blades are perfect for cutting materials with moderate machinability and offer good value in maintenance shops and small fabrication shops. These blades are good for small and medium sized bandsaw machines and the variable teeth pitch can handle a wide variety of sizes. Applications Interrupted cuts: pipe, tubing, angle iron, channel Cutting applications: single piece, bundles, stacked pieces Materials: carbon steels, structural steels - A36 AMAZE M42 These blades are suitable for high production speeds on difficult to machine solids and heavy walled structures. The hardened and strong M42 teeth with a solid backing material cuts solids and heavy walled structures and its variable teeth's pitches can handle a wide variety of cross section sizes. Applications Solids Heavy walled structures Carbon Steels Alloy Steels Stainless Steels Medium to heavy production machines Splender M42 M42 cum grade is known for it's dependably for superb strength to cut mild to tough materials. It can also effectively cut layers and bundles of large profiles and solids. Boasts of excellent performance in a wide range of materials and is a consistent performer with exceptional tooth durability and fatigue resistance Applications Production cutting materials ranging from Carbon to Stainless Steel Layer & Bundle Cuts for cutting Carbon Steel & various kinds of Alloy Steel, Tool Steel & Stainless Steel Large Profiles & Solids of Carbon Steel, Alloy Tooth Steel and Stainless Steel Triumph M51 Highly fatigue resistant to eliminate premature brakeage. Excellent in solid tool steels and small to medium stainless and nickel based alloys. These blades have special high speed steel tooth edges along with a superior alloy steel backing material. Because of the high quality of these blades a fewer blade changes can be done to cover a wider range of materials resulting in lesser downtime.These blades are the finest choice for cutting exotics, stainless steels and large solids. Applications High Production Cutting Solids of Tool Steel Small to medium solids of stainless steel (SS 304/316) Nickel Based Alloys, Inconel & Monel All Machinable Metals in single pieces or bundles High production cutting Stainless steels Exotics, Inconel, Hastalloy

Sample Cutter

Get Price Quote

Best Deals from Cutting Machine Parts

Hob Cutter

8,800 Per Piece

1 Piece(s) (MOQ)

M/S MALKAR INDUSTRIES , offer a wide range of HOB CUTTERS that are available in customized as well as standard designs per client requirements. We offer involute hob cutter for Mikron Hobbing cutter with shortest lead time as the Blanks are ready in stock. Hob Cutter which are widely used in automobile industries are manufacturing from premium grade materials which ensure high durability & functionality. Malkar Industries also have specialization in manufacturing of standard , non-standard hardened , ground gear , spur gear ,helical gear,worm & worm gears, lead screw. Our product range also comprise of Industrial gears, sprockets & spline shafts, spline hob cutters & serration cutters.

Diamond Ring

Get Price Quote

stainless steel Surgical blades

Get Price Quote

Delighting our customers with our excellent performance, we have cemented our status as a top figure in the industry. As a Manufacturer, Supplier and Exporter, we proudly present Stainless Steel Surgical Blades to our customers. These are known for their precise design, durability and sturdiness. We undergo a thorough process of vendor selection to procure raw materials only from the vendors who never fall short of delivering constant and excellent quality.

planer blades

Get Price Quote

Wood surfacing or thicknessing largely depends on quality blades. MCT offers highest quality TCT blades in various sizes. Its precise grinding-without thickness variation-gives uniform working with very sharp edges, that can be grinded over-n-over again for a long life.

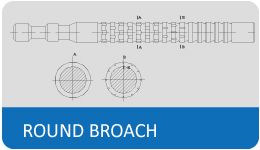

Round Broaches Gear cutting Tools

Get Price Quote

HARBIN TOOL WORKS was set up in 1990, who is a modern enterprise mainly produces gear cutting tools. For more than 20 years’ continuous development, we have acquired powerful capability and adequate production facility. We have got 13 national patents for invention and utility model. Some important operations in the production process are completed on sophisticated foreign facilities imported from Germany, Switzerland, Italy and Japan. We adopt advanced technology from Germany into heat treatment process according to the material and specifications of different products. We have introduced the Swiss Balzers coating equipment, which can be used in various coatings to achieve dry cutting. HARBIN TOOL WORKS not only provides high-precision, high-performance products, but also offers comprehensive and high quality service. After 20 years’ study in gear industry, we become acquainted with the questions and needs of clients in choosing products, purchasing equipments, booking and using cutters. It is a great fortune for us to serve clients with different needs. HARBIN TOOL WORKS has been certified by the quality security standard ISO9001:2008

Squeegee Blade

2,500 Per Piece

TCT Circular Saw Blade

Get Price Quote

We provide best quality TCT Circular Saw Blade that is manufactured using steel with high strength. Our TCT Circular Saw Blade comprises of sharp blade and is corrosion resistant. The TCT Circular Saw Blade is popularly installed in grinding machines. The tungsten carbide Circular Saw Blade, we offer can be availed in varied sizes and different specifications, catering to different clients� requirements. We take pleasure to be reckoned as one of the preeminent TCT Circular Saw Blade Manufacturers and Suppliers in India. Attributes : The raw materials used are heat treatedHighly durableResistant to corrosionSharp blades Application : Installed in grinding machines Used For : Wood CuttingLaminates CuttingAluminum CuttingChannel CuttingBillet CuttingRip Saw

Drill Bits

Get Price Quote

aluminum fan blades

Get Price Quote

10 Piece(s) (MOQ)

The Raw Material I.E. Frp And Aluminium Provides The Desired Non-Corrosive Quality To The Fan Blades, Resulting In The Operation Of Fans Even In The Chemical Environment. Frp Is Lightweight Material Which Ensures Low Moment Of Inertia, Minimum Wear & Tear Of Motor, Bearing And Drive System.Detail : The Basic Purpose Of Fan Is To Move A Mass Of Gas Or Vapor At The Desired Velocity. For Achieving This Objective, There Is Slight Increase In The Gas Pressure Across The Fan Impeller. Sgct Manufacture Fans With Fan Blade Choice Of Correct Twist And Of Special Airfoil Sections To Reduce Compressibility Losses.

shaving blade

Get Price Quote

At GEFI, improving the razor blade is our passion—sometimes we’re evolving it and sometimes we’re revolutionizing it. The best blades that we produce today will provide up to smooth and soft shaving experiences. Quality razor blades are really hard to make, and historically a couple of major brands have controlled almost all of the world’s razor blade factories. They’ve used that position to earn huge profits by selling razor blades at really high prices. That changes today. GEFI is now the only brand in the world that makes blades and sells them directly to you. And we’re committed to selling you our blades for a fair price, so you can get the great shave you deserve without ever overpaying again. Our expertise team has been grinding high-grade steel into some of the world’s sharpest blades. Today, best of our engineers, designers, craftsmen, and production workers build and operate sophisticated, custom equipment that produces millions of precision blades per month. We’re excited to partner with our new team to innovate and continue to make the fine blades you deserve. Our blades will get even better. Your shave will get even better. We’ll listen to your feedback about what makes a great shave and create products that deliver you that experience. In the end, we hope you’ll enjoy shaving even more.IMPORTANT INFORMATION Wake your skin up 1. Avoid shaving as soon as you wake up in the morning. By giving your skin time to “wake up,” you’ll allow it to lose the "puffiness" that happens due to fluid accumulation during the night, allowing you to get a closer shave. 2. Before you shave, make sure to wet the shaving area with warm or hot water. This will cause your hair shaft to swell, allowing the blade to cut your hair and not your skin, preventing infections in case of nicks. 3. You may want to exfoliate using a cleanser or scrub to eradicate dead skin cells. This will better prepare your skin for shaving. Soften your Beard 1. Soak a facecloth in warm water and hold it to your face for 30 seconds. This will help soften and loosen the hair and skin. Lather your Face 1. Put a ball of shaving cream on your palm and apply it evenly over your beard and neck in upward circular motions. Thoroughly massage shaving cream into your stubble. Make sure to uniformly cover all areas of your face that you wish to shave. 2. Try and use a vitamin and Aloe Vera-based cream as this will protect your face from razor rashes and burns while providing you with a close, soothing shave. Choose your Blade 1. Always use a sharp blade to avoid cuts; a dull blade drags instead of slides over your face and catches your skin along with your beard. Rinse the blade in hot water as often as possible. Don’t hurry, use slow short strokes. Just Shave 1. Shave in the direction that your hair grows on your face. This will eliminate redness, rashes, razor burn and ingrown hairs. 2. The top section of your beard: Shave from the top of the beard to the edge of your jaw-line in long, even strokes. 3. Your neck and chin: Shave from the bottom of your neck upwards (with the grain) to prevent razor burn and ingrown hairs. 4. Getting a closer shave: Try pulling your skin taut with your free hand while shaving. 5. Your upper lip: Stretch it over your front teeth to tighten the skin and remember to shave downwards. 6. Rinse your razor after each stroke to keep it from becoming clogged with hair. Take a closer look Wash off excess shaving cream with warm water, and look for sections you may have missed. Wet your razor to shave these remaining sections. Moisturize 1. After shaving, use a toner (preferably containing vitamins, aloe extract, etc.) or after-shave. You could also try an oil-free moisturizer to soothe and protect your face after shaving. 2. If an after-shave lotion is what you use, check the label for alcohol content. Please note that dryness and stinging sensations are caused by most after-shave products that have alcohol as its primary ingredient. Although it may feel good initially, it could turn out to be a minor irritant later.

ANM Cutting Nozzles

240 Per unit

1 unit (MOQ)

Diamond Ring

Get Price Quote

Seller Type:Manufacturer Location:All india delivery Dimensions (L x W x H):0.00 x 0.00 x 0.00 cm Weight:0.00 g Product Code: 1531825479

cutting nozzles

Get Price Quote

Tungsten Carbide Tools

Get Price Quote

We manufacture precision Tooling like Tungsten Carbide Clamping plate, Driving Plates, Tungsten Carbide Shoe, etc. for Bearing Industries, Rolling Industries, etc.

Vegetable Cutter

Get Price Quote

Vegetable Cutter, Make: Sirman (Imported Kitchen Equipment)Hotel Equipment's manufacture in MumbaiApplication: We are engaged in offering Vegetable Cutter, that has been successfully installed in numerous cafes, restaurants and culinary institutes.

hot circular saw blades

Get Price Quote

We are Offering Hot Circular Saw Blades. the Hot Circular Saw Blades Offered By Us are Used in Varied Applications like Cutting of Iron & Steel Billets, Rails, Blooms, Profiles At More Than 700°c Temperatures. Besides, the Hot Circular Saw Blades are Available with Varied Tooth Profiles as per the Requirements of the Customers. attributes : special Steel Used, Excellent Grounding On Both Surface, Diameter Up to 2000 Mm, Fully Hardened and Precisely Milled Teeth, Thickness Up to 12mm.

Rotor Blade

Get Price Quote

Hollow axial aerodynamic composite blade design - for high strength to weight ratio.Periodic checks & maintenance done on mould - for reliable aerodynamic profile of the blade.Snout shape aluminium tip design, to reduce noise and air turbulence, and increase generation output.

Doctor Blades

Get Price Quote

All AkeBoose doctor blades have been carefully selected from the highest qualities of Swedish strip steel for perfect doctoring in flexography and rotogravure printing. Doctor blades offerings include round edge doctor blades and lamella edge doctor blades of a large variety of dimensions and qualities of carbon and stainless steel. The 10 mm wide AkeBoose doctor blades and the AkeBoose back-up blades are specially designed and strongly recommended to be used together with the AkeBoose doctoring systems.