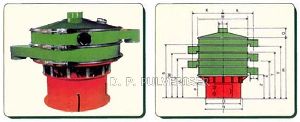

Wet and Dry Screening

The D.P. Vibro Sifter is a circular highly efficient gyrotary screen with adjustable multiplane three component mechanical vibration. The heart of Vibro Sifter is the robust specially made vibrator motor which is designed for long trouble free continuous operation. The vibrator motor has double extended shaft fitted at each end with variable eccentric weight. Motor is rigidly mounted on circular vibrating table on rugged springs. Number of interchangeable spacing frames having discharge outlets along with tensions rings fitted with screens cloth can be mounted one on top of the other, on the Vibrating table with the help of clamp rings. D.P. Vibro Sifter is the most efficient screening machine for any dry and wet sieving application.

...more

universal mill

Universal Mill D. P. Universal Mill The D.P. Universal Mills find applications in fine and ultra fine size reduction of soft to medium hard products, with an upper hardness limit between 3 and 4 on the Mohs hardness scale for minerals. The D.P. Universal Mill casing and doors that can be closed by screwing down a hand wheel. At the rear side of the case there is a bearing body with the drive shaft that runs on rolling bearing and carries the interchangeable crushing elements. Application The D.P. Universal Mills are used for fine grinding or a wide range of material such as, aluminium oxide, bentonitem calcite cardamom, cellulose acetate, chalk, cloves, coating powders, cocoa, corn starch, dextrose, fennel, garlic, gelatine, graphite, gum arabic, gypsum, kaolin, lactose, magnesiun carbonate, melamine resins, metallic stearates, micam milk powder, nutmeg, onions, peetins, pepper, pharmaceuticals, plastics, henna leaves, spices, starch products, sugar, talc, tapioca, zinc oxide, etc.

...more

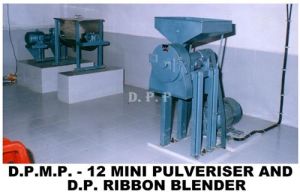

Spice Grinding System

We have three types of pulverizers to offer you for the grinding of spices as under :- 1. D. P. Mini pulverizer is a very simple type of pulverizer. The grinding chamber consists of a serrated ratchet liner on top, and screen at the bottom for classification. Feed material is passed into grinding chamber through a hopper manually. The ground power is collected in a through fitted below the screen, depending on the desired fineness, the number of operations could be 2 or 3 in different types of sieves. During the grinding process, a small quantity of air is generated, to remove this air a Polyester dust bag is fixed below the through and the other end of the bag is hung at a height, also acting like a dust collector. Our D.P. Mini Pulverizers are exclusively ideal for the grinding of small quantity of spices, especially for high value condiments like, cinnamon, cloves, cardamom, nutmeg, pulses, sugar with a capacity from 5 Kgs. To 60 Kgs. Per hour, more ever this machine is also highly capable of grinding wet and pulpy material, like green/red chilly sauce, fresh ginger garlic paste, and other wet and allied food products. The attached illustrated & informative catalog of D.P. Mini Pulverizer attached over separate following e-mails will give you a thorough idea of the type of equipment manufactured by us. We give here below production figures for the same :-

...more

Rotary Air Valve

The D. P. Rotary Air Valves have been designed for absolute universal use. They are ideally suited to control delivery or discharge of powders or palletized products to and from hoppers, bag filters and centrifugal separators. Rotary Air Valve's strong and compact construction makes it a simple matter to access the internal working parts. Size150-175-200-250-300 & 350 mm Standard Design features of Rotary Air Valve • Rotor with beveled tips for powder.• Connection with plug for bearing purging.• Sealing of shaft by means of radial lip seals• System pressure max. 1.5 bar g. Material of Construction for Rotary Air Valve • Housing and side plates in cast stainless steel/cast aluminum or cast iron construction.• Rotor shaft in stainless steel/mild steel.• Gear motor support made of M.S.• Chain drive with M.S. guard.

...more

Ribbon Blender

The D.P. Ribbon Blenders are based on a proven agitator construction that provides a triple mixing action thus ensuring fast efficient blending. The dimensions and configuration of the ribbons in Ribbon Blender are carefully balanced to provide a movement of material within the container that avoids dead spots and gives rapid product discharge. The design of the D. P. Ribbon Blenders can incorporate features required for a customer's product or process such as: wear resistance, corrosive resistance, vacuum filling and discharge arrangements, special shaft seals, heating/cooling jackets. Ribbon Blenders are available in sizes 50-5000 liters in S. S. 304, S.S. 316 & M.S. construction. Triple Mixing Action of Ribbon Blender As the agitator rotates in Ribbon Blender, the material is tumbled and carried radially around the inside of the blender. The pitch of the outer ribbon moves the material towards the discharge opening. The inner ribbon which has a opposing pitch moves the material away from the discharge opening.

...more

Pneumatic Conveying System

Pneumatic Conveying System (Dilute Phase Conveying) Pneumatic Conveying has decisive advantages in conveying dusty products over mechanical conveying, low space requirements and low maintenance. Also it is flexible in construction, can be easily automated, provides dustless conveying without loss of material and is thus also safe for products hazardous to health. A conveyable product is transported through a pipe by using a certain quality of gas [air or nitrogen]. The product particles are freely moving with the high gas velocity and a low product to air ratio. The different types of Pneumatic Conveyors are A) Vacuum Conveying System : D. P. Vacuum Conveying System works on negative pressure for conveying the material from one or number of pickup points to one discharge point. This system is best suitable for providing dust free conditions around inlet. B) Pressure Conveying System : D. P. Pressure Conveying System conveys bulk material by air under pressure. This system offers advantages of conveying material from one place to one or number discharge points. C) Combined Vacuum-Pressure Conveying Systems : D. P. Combined Vacuum- Pressure Conveying System conveys the material from various pick-up points to various discharge points, it is also used where vacuum pick-up and pressure delivery is required. D) Closed Loop Conveying System : D. P. Closed Loop Conveying Systems are designed for handling, explosives and hazardous materials. The conveying gas is usually nitrogen for explosive materials, and dry air is used for handling hygroscopic materials.

...more

micro pulverisers

The D.P. Micro Pulverisers is a high-speed hammer and screen mill, which accomplishes size reduction by mechanically impacting process material. This method of size reduction is characterized by relative high energy and short residence time, minimizing heat build up during the milling process. Operating Principle The D.P. Micro Pulverizers consists of a rotor assembly fitted with hammers and operates generally at high speeds. A cover fitted with a liner, a retaining screen at the point of mill discharge and a feed screw mechanism whereby the unground material is uniformly fed to the grinding chamber. The grinding action in the D.P. Micro Pulverisers is the impact between rapid moving hammers and particles themselves. The energy of the moving hammers dissipates itself into the particles by virtue of their inertia thus causing size reduction. Applications The D. P. Micro Pulverizers, can be used for a wide range of application e.g. Activated Carbon, Animal Feeds, Carbon Black, Chalk, Cocoa, Starch Dyes, Fine Chemicals, Gram Flour, Kaolin, Pigments, Sugar, etc. Outstanding Features• Efficiency and Compactness.• Quick and Easy Cleaning.• Labour Saving.• Long Service Life.• Guaranteed Performance.• Lowest Cost.

...more

Metallic Dross Separation System

The D. P. Impact Pulveriser is modified for metal dross separation. The metalic dross to be separated is crushed in the crushing chamber, care is taken during crushing, that the pure metal is not crushed into very fine particles size, as this metal is very difficult to recover. In the crushing chamber, a suitable door is provided for the separated metal to get discharged. The quality of this metal (i. e. percentage of pure metal) is in form of granules and oxides, depend on the percentage of pure metal in the dross. If the dross is of high metal content, then the discharge through the door is of high purity. If the dross is of low metallic content then, with the metal granules there is a small percentage of oxides. This mixed metal with oxides needs to be sieved. The whizzer classifier obstructs the pure metal granules to pass into the blower, however some particles escape from the whizzer and enter into the blower. This material from the blower is taken to a pre cyclone, to remove all the pure metal granules entering into the cyclone, so the material collected in the cyclone is only oxides. The outlet of the cyclone is connected to a dust collector, so all fine oxides are collected in the dust collector

...more

Impact Pulveriser / Pulverizer

The D.P. Impact Pulveriser / Pulverizer is a versatile grinding unit of heavy and rugged construction and built for continuous operation day after day. The unit is especially designed for the medium fine, and fine size reduction. The Pulverisers meet most capacity requirements and lend themselves to a wide degree of adjustments with fineness of the finished product ranging from about 60 mesh to bulk passing through 325 mesh, depending on a considerable extent to the particular material being handled. Unlike an ordinary hammer mill, it has no screens to break, wear out or clog in the crushing chamber. The D. P. Impact Pulverizers combines grinding, classifying and conveying all in one single unit. Operating Principle of Impact Pulveriser The D.P. Impact Pulveriser consists of an encased rotor carrying swing hammers, whizzer classifier for fineness regulation, and Blower Fan mounted on a solid shaft. Raw material to be pulverised enters the crushing chamber through the hopper and automatic rotary feeder. The impact of the hammer on the feed material against the Liner plates reduces it into fine powder. The ground material is carried towards the whizzer classifier for classification and the over size particles are rejected by the classifier and returns to the crushing chamber for further grinding. The classified material is then conveyed into the cyclone for collection and bagging. A dust collector is provided in the system for ensuring dust Free operation and no loss of ground powder. Application of Impact Pulveriser The D. P. Impact Pulverizers are used for a wide range of application e.g. Agricultural Chemicals, Carbon & Graphite, Coal, Coke, Coconut Shell & Wood Saw Dust, Clay, Dye Stuff & Pigments, Detergents, Ferro Alloys Fertilizers, Fillers, Food Products, Herbs & Spices, Insecticides and Pesticides, Katha, Marine feeds, Minerals, Plastics, Pharmaceuticals, Resins, etc. Outstanding Features of Impact Pulveriser * Easy starting.* Cold & silent running* Dust free operations* Robust Construction * Low Specific Power Consumption* Automatic Feeding* Durable Long Life* Guaranteed Grinding Efficiency

...more

Impact Crusher

D.P. Pulverisers manufacture a large variety of Impact Crushers to virtually any size reduction job. The extremely rugged construction of Impact Crushers ensures a long life with minimum maintenance easy to install and economical to run. The shell of Impact Crusher is lined throughout with MS, Cast Iron or Manganese Steel, according to the size of Impact Crusher and duty required. We can provide a Impact Crusher to reduce almost any material to the size required. Operating Principle of Impact Crusher Material is fed in Impact Crusher from the periphery through a hopper into the grinding chamber to minimize air pressure, greatly reducing dust problems. For some material suitable ventilation is recommended by introducing air on the discharge side of the crusher, this will prevent a dusty atmosphere at the inlet of Impact Crusher. The swinging hammers in Impact Crushers crush the materials along the stationery liners before discharging through a perforated screen at the bottom; replaceable bar type screen is available for specific application. Combination of hammer style, liner plates and sieve inserts offer almost unlimited possibilities to cater user needs from an Impact Crusher. Applications of Impact Crusher The Impact Crushers are used for crushing or shredding of diverse materials such as: Limestone, Glass, Coal and Lignite, Clay, Sand, Phosphate, Rock, Fertilizer, Aluminium Oxide, Slags, Coke, Silica, Bauxite, Dolomite, Grain, Barytes, etc. Outstanding Features of Impact Crusher Impact Crusher is specifically designed to withstand the abuse of grinding of abrasive materials. Heavy duty, replaceable, abrasion resistance wears plates in mill top. Heavy duty hard faced or heat treated hammers. Heavy duty rotor assembly. Rugged bar screen or thick perforated metal screens to size materials. Impact Crusher is opted with Dust-tight or water-tight construction. All stainless steel construction available in Impact Crusher.

...more

Dust Collector

Pulse Air Cartridge type Dust Collectors. Applications of Dust Collectors Cartridge type dust Collectors are Cartridge filters with automatic cartridge cleaning by compressed air pulses. Dust Collectors serves for the dry separation of dust from exhaust air in areas like: Plastic Processing Industries Pharmaceutical Industries Food processing Industries Cement and Mineral Industries Powder Coating Industries Pneumatic transport of solids Air conditioning Plants Characteristic Features of Dust Collectors. Pleated filter material offers multifold filter area [5 to 6 times] compared to standard filter elements with same specific dust loading in Dust Collectors. Highly efficient filter cartridges imported from R & B filter GmbH. Germany is used in Dust Collectors. Filter medium in Dust Collectors made of paper or synthetic non- woven material made of needle felt depending on application. Compact construction leading to modest floor space requirements. Dust Collectors low compressed air consumption combined with high efficiency reverse pulsejet cleaning with venturi nozzle. Operating temperatures up to 80 degree centigrade and up to 200 degree centigrade on request. Material of construction in Dust Collectors: stainless steel or mild steel. Long life - better quality- economical and reliable solution to any dust extraction problems. Complete filter unit quipped with compressed air header, pulse piping valve, pulse timer, Filter Cartridge, venturi nozzle and pressure manometer

...more

Air Classifying Mill

Air Classifying Mill is used for separating dry materials into different particle size fractions by their size, mass or shape also modify a particle size distribution. We have established a note worthy status among the Air Classifying Mill Manufacturers in India. We bring for the clients Air Classifying Mill of exceptional quality at cost-effective price. Known For : Resistance to wear and tear Sturdy build Easy installation Compactness Simple design Low maintenance Cost-efficiency Superior quality Operating Principle Referring to the schematics below, most of the processing air or gas enters through the bottom section of the mill. Up to 30% of the total airflow can be introduced with the feed material. Concurrent with this constant mass flow of gas, feed material is introduced to the mill ideally in a constant mass flow manner. For most applications, material is introduced to the tip of the rotating hammers through a port opening at the side of the mill. Feed material can be either pneumatically conveyed or screw fed. The rotating hammers attached to the impact rotor disc serve to fracture the process material. A serrated liner mounted on the periphery of the grinding chamber in the hammer path serves to improve grinding efficiency by preventing particles from accelerating to the speed of the hammers thereby increasing the relative speed difference. The primary airflow passing through the narrow annular gap formed in between the liner and impact rotor disc in conjunction with the fanning action of the hammers transports the material to the top of the mill. A dispersion ring then directs the material downward toward the classifier. Baffles welded to a shroud ring straighten the flow of material and air so that particle vortexing at the dispersion ring area is avoided.

...moreBe first to Rate

Rate ThisOpening Hours