Vacuum Gauge

Get Price Quote

Vacuum gauge, The Glycerin filling helps dampen the effect of the vibration & pulsation. It also lubricates the movement which extends the life of the gauge. Glycerin also enhances the reliability and integrity of pressure gauges for long period under 3extreem operating conditions.

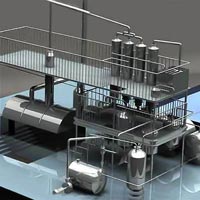

Cip System

Get Price Quote

Our company is prominent CIP System Manufacturer in India offering highly efficient and top performance CIP Systems to our esteemed clientele. Clean-in-place (CIP) is a method of cleaning the interior surfaces of pipes, vessels, process equipment, filters and associated fittings, without disassembly. Industries that rely heavily on CIP are those requiring high levels of hygiene, and include dairy, beverage, brewing, processed foods, pharmaceutical, and cosmetics. The benefit to industries that use CIP is that the cleaning is faster, less labor-intensive and more repeatable, and poses less of a chemical exposure risk. Our offered Modular CIP Systems are manufactured with latest technology at state of art facility under the supervision of our engineering experts. Quality control is our priority and ensures that all our offered Vent Filters are passed laid quality checking procedures, thus makes us ultimate choice as suppliers of Modular CIP Systems in India. As reliable exporters of CIP Cleaning Systems, our offered products are appreciated for their efficiency, corrosion resistant, durability, easy operation and easy maintenance. We are offering finest quality Vent Filters at competitive prices available in the market.

Best Deals from Dairy Processing Plant

Pressure Gauge

Get Price Quote

We are instrumental in manufacturing and supplying of pressure gauges, which are specially designed to meet the requirements of different industries. Pressure gauges offered by us, are known for their accuracy and high efficiency in the domestic as well as international market.

Clean In Place System

400,000 - 1,000,000 Per Piece

1 Piece (MOQ)

Clean-in-place (CIP) is a method of cleaning the interior surfaces of pipes, vessels, process equipment, filters and associated fittings, without disassembly.Closed systems were disassembled and cleaned manually. The advent of CIP was a boon to industries that needed frequent internal cleaning of their processes. Industries that rely heavily on CIP are those requiring high levels of hygiene, and include : dairy, beverage, brewing, processed foods, pharmaceutical, and cosmetics.The benefit to industries that use CIP is that the cleaning is faster, less labor-intensive and more repeatable, and poses less of a chemical exposure risk. CIP started as a manual practice involving a balance tank, centrifugal pump, and connection to the system being cleaned. Since the 1950s, CIP has evolved to include fully automated systems with programmable logic controllers, multiple balance tanks, sensors, valves, heat exchangers, data acquisition and specially designed spray nozzle systems. Simple, manually operated CIP systems can still be found in use today. Depending on soil load and process geometry, the CIP design principle is one of the following: deliver highly turbulent, high flow-rate solution to effect good cleaning (applies to pipe circuits and some filled equipment). deliver solution as a low-energy spray to fully wet the surface (applies to lightly soiled vessels where a static spray ball may be used). deliver a high energy impinging spray (applies to highly soiled or large diameter vessels where a dynamic spray device may be used).

Butter Milk Pouch Packing Machine

135,000 Per Piece

1 Piece (MOQ)

Vacuum Gauge

Get Price Quote

We are offering vacuum gauge sensor – thermistor type. resolution as low as 1 micron. 1/2 second response time. provides accurate measurement fast. makes evacuating a system easy! reads in 7 international units. a quality product from supco, usa.

CIP AND SIP Systems

Get Price Quote

KERONE along with its dedicated team of process equipments machinery manufacturing and design team and technically equipped manufacturing facilities has helped in succeeding in providing the high quality and technically advanced process equipments for the various need of the CIP/SIP Systems Plant. CIP (Clean-in-Place) systems offers the arrangement for cleaning/sterilizing the interior surfaces of vessels, equipment, filters, pipes and fittings, without disassembling them. SIP(Steam-In-Place) Systems are liable for frequently steaming parts of product contact, vessels, flow paths, and sample ports. The CIP/SIP systems together helps in maintaining the desired level of hygiene, by continuously killing the germs.

CIP Tank

Get Price Quote

Online parameters Completely automated process cycle Online PH conductivity,TOC sensing Single to multitank system

milking machine parts

Get Price Quote

Milk and milk products are one of the most likely foods to be spoiled by bacterial contamination. A definite hygiene program is a prerequisite for all stages of milk production. Iodophors are extensively used in Great Britain, the United States, Australia, New Zealand etc. and its effectiveness as cleaners and sanitizers is well-established. POLYSAN-D is an iodophor product containing ‘Tamed Iodine’ complexed with non-ionic surface agent and phosphoric acid. Active ingredients: Available iodine 1.6% alkyl phenoxy poly oxyethylene ethanol (surface active agent), phosphoric acid 10%.

Vacuum Gauge

Get Price Quote

“Telelin” make Mc-leod gauges measures absolute vacuum in its very last stages. Mc-leod gauge manufactured by us are used by OEMS and various Oil companies for measuring vaccum . Thus our large client base and repetitive orders have made us amongst the leading manufacturer, exporter & supplier of Mc-leod gauge in Mumbai, India . Model No : MG-6 Portable Mc-leod gauge, with stand & 1st fill Mercury. The vacustate suitable for measurement of vacuum in the range : 10 mm. to 10-3mm of Hg. (i.e. 10 mm. to 0.001 torr) with stand & 1st Mercury. This gauge avoids use of a movable reservoir of mercury and also requires only about 14 cc. of mercury for first filling. The total size of this gauge is about 9” x 6”. Metallic stand with Rotating arrangement & 1st fill mercury is provided. WORKING OF THE GAUGES : The system of which vacuum is to be measured, is connected by flexible rubber tubing to nozzle on the back centre of gauge at A. Gauge is in Horizontal position-1 initially. To take vacuum reading, gauge is to be rotated in the vertical position-2. Mercury runs out of the container B, compressing the residual air or gas. contained within region C & D, to short length of capillary tube C & E. By arranging that the level in the comparison capillary F is opposite the end of the graduated capillary C & E, slight adjustment of gauge above the vertical axis is needed to adjust the mercury level correctly. the Reading in tube C-E is absolute Vacuum in mm of Hg in your line.

Cip System

180,000 Per Piece

CIP is commonly used for cleaning bioreactors, fermenters, mix vessels, and other equipment used in biotech manufacturing, pharmaceutical manufacturing and food and beverage manufacturing. CIP is performed to remove or obliterate previous Cell Culture batch components. It is used to remove in-process residues, control bioburden, and reduce endotoxin levels within processing equipment and systems. Residue removal is accomplished during CIP with a combination of heat, chemical action, and turbulent flow. The Code of Federal Regulations states “Equipment and utensils shall be cleaned, maintained, and sanitized at appropriate intervals to prevent malfunctions or contamination that would alter the safety, identity, strength, quality or purity of the drug product beyond the official or other established requirements.”[1] Repeatable, reliable, and effective cleaning is of the utmost importance in a manufacturing facility. Cleaning procedures are validated to demonstrate that they are effective, reproducible, and under control. In order to adequately clean processing equipment, the equipment must be designed with smooth stainless steel surfaces and interconnecting piping that has cleanable joints. The chemical properties of the cleaning agents must properly interact with the chemical and physical properties of the residues being removed. A typical CIP cycle consists of many steps which often include (in order): Pre-rinse with WFI (water for injection) or PW (purified water) which is performed to wet the interior surface of the tank and remove residue. It also provides a non-chemical pressure test of the CIP flow path. Caustic solution single pass flush through the vessel to drain. Caustic is the main cleaning solution. Caustic solution re-circulation through the vessel. Intermediate WFI or PW rinse Acid solution wash – used to remove mineral precipitates and protein residues. Final rinse with WFI or PW – rinses to flush out residual cleaning agents. Final air blow – used to remove moisture remaining after CIP cycle. Critical parameters must be met and remain within the specification for the duration of the cycle. If the specification is not reached or maintained, cleaning will not be ensured and will have to be repeated. Critical parameters include temperature, flow rate/supply pressure, chemical concentration, chemical contact time, and final rinse conductivity (which shows that all cleaning chemicals have been removed).

Fancy lock dairy small

1 - 30 Per Pc

320 Piece (MOQ)

Tofu Pressing Machine

Get Price Quote

digital vacuum gauge

Get Price Quote

Pan Welding Machines

Get Price Quote

We, Sparkweld Engineering, Mumbai, are manufacturer and supplier of world class Utensil Stud Welder (Pan Welding Machine). With the diverse application in its portfolio, Pan Welding Machine serves the variety of kitchenware manufacturer in India. The main feature is excellent aesthetic in welding. Pan Welding Machine serves simple as well as a complex application so won the trust of kitchenware manufacturer as they want the latest technology to create best and innovative products. Our specialized Pan Welding Machine efficiently serve the vast diversity of kitchenware which is key to growth and profitability of every manufacturer. Features: Excellent aesthetic in welding. Fully pneumatic control and pneumatic lift facility. Easily adjustable height. Robust and lightweight. Aluminium construction to restrict magnetic influence. Different angle adjustment on welding head and pan bolster for angled welder fixings. Adjustable air control and interchangeable bolster arrangement. For the correct stud position on pan wall, linear movement of the front plate is provided. Specifications: Brand: Sparkweld Engineers. Product Code: SE-06. Type: Stored Energy Discharge. Welding Head Operation: Pneumatic. Welding Head: Initial Contact Type. Stud Range: Up to 10mm square aluminium. Base Material:1.2mm and above. Gas: Argon 99%. Input Supply Voltage: 240v,A.C.,10Amp. Charging Voltage:60 to 180 volts, D.C., Stepless.

VACUUVIEW Vacuum gauge

Get Price Quote

VACUU·VIEW For the monitoring of your vacuum processes in the rough vacuum range, the new vacuum gauges VACUU·VIEW are perfect! Chemically resistant ceramic diaphragm sensor for measurement in the rough vacuum range. VACUU·VIEW provides gas-independent pressure indication with precise capacitive readout. Performance features highest precision in the range from atmosphere down to 0.1 mbar, perfect gauge for all rough vacuum applications compact design with integrated sensor for useful setup in laboratory and process chemically resistant ceramic diaphragm sensor, highly reliable at harsh laboratory conditions even in case of aggressive chemicals illuminated display, easy to read Display with menu driven handling easy to use e.g. for unit settings

milking parlour

Get Price Quote

Increasing productivity and efficiency in the dairy industry means creating new ways to keep the animals comfortable together when they need to be milked. Animals that give milk for domestic consumption tend to be fairly docile herd animals. These are animals that will feel more comfortable once they see more of themselves in the same location performing the same activity. They believe that this is expected of them as a group and not as individuals. Though each animal may be milked individually, simply keeping them together makes the process much more comfortable for the animals. This, in turn, makes the job of the dairy producers much easier for the people who have to monitor the animal activity. So when cows need to be milked, open air areas can’t be utilized. Instead, it is done in an enclosed space to protect the humans and animals from any natural contaminants like rain and insects. The cows are traditionally put into cowsheds when they get milked. Modern dairy producers use milking parlors to get the maximum yield from their herd. These milking parlors have different set ups and shapes to accommodate the animals and the lay of the land. Most layouts tend to be customized for optimum efficicency. The simplest method is to set up the milking parlor in parallel lines where the straight lines give the most organized look for the milking parlor. When looking at milk parlors for sale, the size and shape of the dairy is the first thing that has to be looked at when planning for a design. The tandem parlor, the herringbone parlor and the rotary parlor are among the other design layouts on milking parlors for sale. The Krishna Allied Industry milking parlors are high in performance and durability with very low maintenance required to keep it running. It has followed a design to suit Indian conditions. Stainless steel milk lines, milk pre-holders and milk transfer pumps are used in all designs for improved milk quality. The most important feature of our milking parlors is that they are ideal for an expanding herd. To know more about milking parlors from Krishna Allied Industry, download our brochure.

Butter Wrapping Machine

Get Price Quote

the micron cube forming machine is designed to pack butter and similar kind of products in parchment paperor aluminium foil as per the requirement of the customer. the operation:the complete machine is a mechanical machine with a rotary table. The paper or the foil in the form of a roll will be fed to the machine. The machine will automatically sense the length of the paper & cut the same in a correct size. the specially designed format pushes the paper into the cassette on the table where the two side’s get folded. the paper is sensed and move to next station where the desired quantity of the products gets dispersed into it. the specially designed screw feeder is used to transfer and dispense the product. At the next station the papergets folded and then pressed to get the desired shape. The finished product then gets rolled on to the conveyor. listed below are some of the features of the machine: very compact design less maintenance output of the machine up to 70-90 bricks per minute

CIP System 20

Get Price Quote

We are offering a very useful gamut of Vessel & Pipe Cleaning Machines and vessel cleaning machines which have been beckoning the attention of shoppers spreading world wide, and accumulating the praise in volumes from our prestigious clients. Our endeavors led us on the top among the pipe cleaning machines exporter situated in India. These vessel & pipe cleaning machines are installed with of advance technology which comes in result of highly innovative products. We follow all the methods and standards required for exporting our genuine products. These are accessible at market leading prices. Product Specification Automated Cleaning-in Place for Vessels and Piping Mobile manual units Mobile PLC base Auto Units Fixed CIP Stations Unit Consists of: CIP Tank Supply and Return Pump Heater Piping and Valves Dosing System Instrumentation and Automation.

Vacuum Gauges

270 Per Piece

Butter Churn Machine

30,000 Per Piece

Mechanical Vacuum Gauges

Get Price Quote

milking parlor

Get Price Quote

When looking at milk parlors for sale, the size and shape of the dairy is the first thing that has to be looked at when planning for a design. The tandem parlor, the herringbone parlor and the rotary parlor are among the other design layouts on milking parlors for sale. The Krishna Allied Industry milking parlors are high in performance and durability with very low maintenance required to keep it running. It has followed a design to suit Indian conditions. Stainless steel milk lines, milk pre-holders and milk transfer pumps are used in all designs for improved milk quality. The most important feature of our milking parlors is that they are ideal for an expanding herd. High performance, durable and reliable design Very low maintenance require High cow flow efficiency Customized design facility Ideal for expanding herd Ease of cleaning Sturdy Indian design Optimized farm productivity Auto Wash System All pipes which milk touch clean property Always same quantity water consumption Optimum disinfection dosage Rinsing water may reheat again Pre-rinse out by adjustable time Easy programming reduces faults Computer adaptable Cubicles High cow comfort Cows completely free Easy installation Adjustable Flexible Positive influence on milk production Cattle Lock System Protect udder heal Grouped feeding possibility Secure and comfort feeding possibility Balanced alimentation possibility Usage facility with practical on off rod

Portable Cip System

Get Price Quote

Useful as a common CIP system for non movable equipments which cannot be moved to cleaning area like Blenders, RMG, Fluid dryers mixing tanks, storage tanks, etc. which do not have their own dedicated CIP arrangement.

CIP/SIP MODULES

Get Price Quote

Clean-In-Place (CIP)/ Steam -In-Place (SIP) technology offers significant advantages to manufacturing facilities from efficient cleaning of process equipment & piping at lower costs to improved product quality CIP Systems are fully integrated incorporating tanks, pumps, valves , spray cleaning devices, ,heat exchangers, piping & controls without the need to disassemble all or part of the system, significantly reduces cleaning costs and minimises the handling of chemicals to provide a safer environment for plant personnel.CIP CYCLEThe CIP process involves asequence of cycles that includes an initial and final drain step, a pre-rinse and post-rinse step.the CIP process may include a sanitise cycle to reduce the levels of bacterial contaminants This cycle uses aqeous solutions of strong oxidants such as hydrogen peroxide, ozone and chlorine containing compounds.CONTROLSThe cotrols incorporated into CIP systems arecritically important and provide a variety of cycle times, temperatures, composition of cleaning solutions. Fully automated PLC based CIP systems are offered to suit customer specifications.

Clean In Place System

Get Price Quote

We are the major Manufacturer, Supplier and Exporter of Clean In Place System in the market. Cleaning In Place System (CIP System) involves the mounting of water nozzles at strategic positions in the dryer installation. Cleaning-In-Place systems are designed for automatic cleaning without major disassembly and assembly work. This feature is essential where multiple products are dried in a single system and frequent washing is required. Features : Anti corrosiveReliableDurableOperator friendly

Pressure & Vaccum Gauges

Get Price Quote

We are Offering Pressure & Vaccum Gauges. Gauges used for measurig Pressure & vaccum

Dairy Equipment

Get Price Quote

Besides rendering standard dairy projects we have developed an innovative concept of installing all dairy equipments inside a standard export container. The container is designed in order to prevent construction of additional building for the installation of such equipments for the project. With appropriate placement of the plant where there is constant supply of the power and drinking water, the equipment works uninterrupted. The Dairy Equipments offered by us possess production capacity of 1000 to 1500 Ltrs. of Milk per hour. Moreover, the Dairy equipments are well-suitable for both fresh Milk as well as powdered Milk.

Vacuum Gauge

Get Price Quote

Offers vacuum gauge.

Dairy Equipment

Get Price Quote

Idmc provides comprehensive range of quality dairy equipment in india.