Zipper Tape Carrier

We are offering zipper tape carrier, suitable to receive various sizes of spools (bobbins).

...more

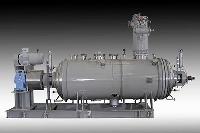

wiped film evaporator

We are offering wiped film evaporator. The wiped film evaporator is used for concentration, distilling, stripping, dehydration and deodorisation of products which are heat sensitive or viscous. The equipment can handle a very wide range of feed compositions ranging from 1% to over 95% concentration. Wfe has several advantages as stated in the table below. The operation is continuous with a single pass; the self cleaning continuous contact wipers produce and renew the thin film. Such an operation improves product yield, avoids residue and colour formation. It has an internal condenser (optional) that minimizes the pressure drop and maintains vacuum

...more

waste water filtration system

We are offering waste water filtration system. To increase the attention towards ecology and environment, dalal has introduced a waste water filtration and recycling system. It is an automatic and economical water treatment system with easy application and without need for specialised manpower. The system consists of one sedimentation and one clean water tank. The dirty water is passed through a high speed filtration system for removal of suspended solids and then cleaned water is collected in clean water tank.

...more

Vibro Energy Separators

Vibro Energy Separators is achieved by mounting eccentric weights on the top and bottom of a special heavy-duty motor with extended shafts on both its ends. Vibration can be varied by addition or removal of auxiliary weights and by changing the angle between the top and bottom eccentric weights. This allows control of amplitude as well as material flow patterns.

...more

Vibro Energy Separator

Vibro Energy Seperators are used for screening and grading of dry powders and screening of slurries. The machine is a proven performer for applications as diverse as abrasives, ceramic powders and slurries, chemicals, pharmaceuticals, powder coatings and slurries, minerals, metal powders, and food products. Working Principle The machine is a rigid screening device that vibrates about its center of mass. Vibration is achieved by mounting eccentric weights on the top and bottom of a special heavy-duty motor with extended shafts on both its ends. Vibration can be varied by addition or removal of auxiliary weights and by changing the angle between the top and bottom eccentric weights. This allows control of amplitude as well as material flow patterns.

...more

vibro energy finishing machine

Our product is available in nontoxic and industrial-grade packaging materials that ensure the products are safe from damage and reach buyers in brand new conditions. Our facility in Mumbai-400 021(India) is well connected by a variety of modes of transportation. Thus, we are able to reach customer anywhere.

...more

Vibro Dryers

Vibro Dryers are designed for stainfree drying and polishing of components, immediately after vibratorycentrifugal finishing.Heated MaizorbCorncob is used as the drying media. The rubbing action of the mass eliminates the calcarious residuals of the evaporated water deposited on the surface of the parts. The equipment is offered in, both, batch and continuos operations.

...more

Vibratory finishing equipment

Vibratory Finishing Machines are mass finishing machines, used for deburring, polishing, descaling, and surface improvement on metal and plastic components. Working Principle The machine has a steel bowl lined with rubber or polyurethane which is filled up with required media (either ceramic, plastic, maize etc. depending upon the finish required) and components. Eccentric weights are mounted on an extended shaft attached to a heavy duty motor to cause vibrations and create a spiral of the media and the components. Variations in vibration, achieved by varying weights and angles, and suitable combination of media enable machine to be used for different components.

...more

Vibratory Finishing

Vibratory Finishing are mounted on an extended shaft attached to a heavy duty motor to cause vibrations and create a spiral of the media and the components. Variations in vibration, achieved by varying weights and angles, and suitable combination of media enable machine to be used for different components. Efficient removal of process fluid for best surface finish. Bowls shot blasted before and after Polyurethane lining for painting.

...more

Tub Vibro Finishing

Tub Vibro Finishing This results in efficient processing of components. Vibration can be adjusted with eccentric weights and systems can be batch type, continuous or customized as per needs. Machine can be customized to suit parts, Can handle small to very large and very long parts.

...more

Supertor

We offer Supertor. This ability to carry out two, sometimes three unit operations makes the SUPERTOR extremely versatile and useful. It sizes, reduces, grinds, delumps, chops, disperses, separates, macerates and even pumps and has been installed for various slurry handling applications viz.

...more

Sound Reduction Accessories

We are offering sound reduction accessories,. For workers safety and to meet factory sound norms, mass finishing equipment usually requires noise protection measures. sound cover – noise protection cover of single machine with a manually or pneumatically operated hinge type cover, covering only the top of the machine. sound protection cabin - a sound protection cabin with a complete enclosure and manually openable top and sides

...more

Solvent Recovery System

Two well known names AMCEC, USA and Dalal Engineering, India have come together to offer perfect solutions in the field of Solvent Recovery. So you get the benefit of AMCEC’s established technological expertise and Dalal’s proven engineering skills. AMCEC is a recognized leader in the fields of vapor phase solvent adsorption using activated carbon and solvent recovery. It has over 80 years of worldwide experience, and with thousands of systems in operation, helps companies recover millions of kilos of solvent VOC’s each year.

...more

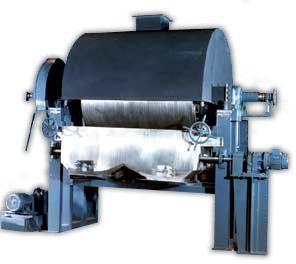

rotary vacuum dryers

We are offering rotary vacuum dryers. Rotary vacuum dryers offer clean, simple and effective method of drying wet cake, powder and even slurry. Labor and energy costs are minimal compared to tray dryers and product losses during handling are also negligible. Additionally valuable organic solvents can be conveniently condensed and recovered.

...more

Rotary Vacuum Dryer

The drying in a rotary vacuum dryer is a batch operation under vacuum. It is possible to dry heat sensitive materials at well below boiling points of water and solvents. Drying time depends on material being dried, amount of solvent or water to be removed, desired final moisture content, permissible jacket temperature etc. The dryer is available in sizes ranging from 100 liters to 20,000 liters gross volume. The volume of wet material loaded into the dryer is usually restricted to 40-45% of gross volume.

...more

Rapid Ball Burnishing Machines

Rapid Ball Burnishing Machines are the best solution for polishing of components where there is need of a high production short process time. These machines can work in batches for polishing of small and medium sized parts.These machines have a high frequency technology where the total process times are between 10-20 minutes.

...more

Package Dyeing Machines

Dalal is a leading manufacturer of package dyeing machines offering complete dyeing and drying solutions for capacities ranging from 1 kg to 2000 kg or more. Our machines are universal – capable of dyeing natural or man-made fibre in a variety of forms. Our current range of machines is now more eco-friendly, with features like air pad system for reduced water, steam, power and dyes chemicals consumption and variable frequency drive for greater energy efficiency.

...more

Lab Dyeing Machine

In an elegantly designed pilot plant Dalal offers the high-temperature high-pressure version to dye samples of yarn, fibre, slivers of various substrates with suitable material holders. This is very useful for standardizing the recipes of dyeing before batches are taken in bulk. This avoids trial and error methods, thus saving on time, and resources utilized. From the study of the results, it will be possible to estimate production cost and maximize profit margins Salient Features : Fully automatic operation using latest control systems for process sequences and valve operations. Good dyeing of even large packages with high density. Size can vary to receive between 1 to 5 packages.

...more

Flaker machine

The hot material is applied to the cooling drum by direct immersion into a trough, or indirect immersion using doctorapplicator rolls. The molten liquid is cooled on the cooling drum and after a partial revolution; the cooled and solidified product is removed by a scraper in the form of flakes or film. The cooling drum of the flaker is specially designed to provide an even cooling effect by having uniform and effective internal distribution. As a result, both high output and homogeneity of the product are possible.

...more

finishing machinery

We are offering finishing machinery. At dalal, we don’t sell machines, we provide solutions. Over the years we’ve handled the tiniest automobile components to the most complex aviation equipment; the thinnest of delicate wires and the largest and roughest of engineering components, bringing a shine to hundreds of varied surfaces (and a smile to every manager’s face!). Each time a new customer comes to us, we study and understand, we consult our database of over 12,000 diverse case studies, we conduct trials and research in our advanced r & d lab, and we devise a tailor made solution for you.

...more

Falling Film Evaporator

The Wiped Film Evaporator is used for concentration, distilling, stripping, dehydration and deodorisation of products which are heat sensitive or viscous. The equipment can handle a very wide range of feed compositions ranging from 1% to over 95% concentration. WFE has several advantages as stated in the table below. The operation is continuous with a single pass; the self cleaning continuous contact wipers produce and renew the thin film. Such an operation improves product yield, avoids residue and colour formation. It has an internal condenser (optional) that minimizes the pressure drop and maintains vacuum.

...more

Drum Flaker

Drum flakers (also known as cooling drums) are used for solidifying molten material. After processing on flakers, the material forms films or easily handled flakes and is further processed or packed into containers for transport. A great advantage of flakers is that they offer a continuous process. Salient Features : Variable speed drive arrangement for adjustment of the drum speed for optimum performance, Suitable for a wide range of chemical and pharmaceutical products, Contact parts can be stainless steel, carbon steel, and hard chrome plated depending on material requirements, Accessories include hood, flake breaker, flake conveyor, applicator roller etc.

...more

Disc Finishing Machines

Disc Finishing Machines are designed for optimumdisc and chamber life with greater thickness of polyurethanein the high wear areas. A special sealing arrangement ensures a longer life of rotating disc and does not require frequent gap adjustment.Discharge of the work mass can be done manually or by an automatic tilting arrangement.

...more

Disc finishing machine

Disc finishing machines are also high ‘G’ force machines which work faster due to the centrifugal force generated by a rotating disc. Process times are significantly lower than Vibratory Finishing Machines but somewhat more than Centrifugal Finishing Machines. The advantages of Disc Finishing over Centrifugal Finishing are the greater ease of loading and unloading and the possibility of In-process inspection of parts. They are usually suitable for small components

...moreBe first to Rate

Rate ThisOpening Hours