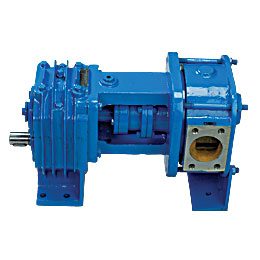

Two Spindle Screw Pump

10,000 - 200,000 Per Piece

A pair of specially profiled screw, machined integral from solid stock and well supported on antifriction bearings run in precision bored interchangeable casing liners. Each screw set has one right hand and one left hand screw engaging with a similar but opposite hand screw pair. A pair of hardened and profile ground timing gears synchronize the screws to maintain a small but positive clearance between the flanks thus ensuring no metal to metal contact. The pumps can therefore run dry for sometime without any damage. This unique feature enables to run the pump even dry and handle fluids that do not have enough lubricating value and also very low or high viscous products. Consequently, since there is no metal to metal contact; wear and tear is reduced to the minimum, ensuring extremely long service life. With two pairs of screws running in the same casing, the internal velocities are very small - consequently the NPSHR is practically the lowest even when the pumps run at motor speeds and while handling viscous products. Opposed screw pitches totally eliminate axial thrusts. Relatively small diameters of screws enables the pump to operate at high speeds directly coupled to prime movers - without the need for speed reducers even while handling high sealing’s always under suction pressure, thus making use of simple, inexpensive seals. The axial flow without turbulence, rotation, churning, chewing guarantees gentle handling of products. Noise and vibration or ---- levels are about the lowest. Positive clearance between running parts makes it easier to construct the pump in different materials safely, especially in stainless steel, without the fear of seizing. Thus a variety of fluids can easily be handled by selecting the right materials of construction. Typical Parameters Temperature: -30 to +350°C Viscosity: 1 cSt to 50,000 cSt or more Capacity: 20 to 500 m3/hr Pressure: Normal 16 bar/ 24bar, with special designs up to 50 bar Specialties: Partial heating/ complete heating/ cooling arrangements Sealing: Stuffing box/ mechanical seal with or without quenching/ heating/ cooling Mounting: Horizontal foot mount/ vertical pedestal Accessories: Relief valves, base frame, coupling, coupling guard, companion flanges, pressure gauges, electric motor/ diesel engines, variable speed drives and as per customer requirements. Typical Applications Loading / unloading of fuel oil and other products from: Railway wagon rakes, Truck tankers, Barges, Ships and Tankers. Bulk cargo handling. Lubrication, circulation and cooling. Process pumping of high viscous products, bitumen, molasses, soap and similar products. Long distance pipeline pumping of viscous products.

...more

Twin Screw Pumps

5,000 - 600,000 Per Bag

A pair of specially profiled screw, machined integral from solid stock and well supported on antifriction bearings run in precision bored interchangeable casing liners.

Material : Temperature: -30 to +350°C

Color : blue

...more

Three Screw Pumps

50,000 - 200,000 Per rs

Three Screw Pump ( Series D3S/SMT/SMT16B )

20,000 - 500,000 Per Rs

Settima-Delta Three Screw pumps employ just three screw elements - one power screw and two idler screws running in the three precision bores in the housing or liner. The screws are so profiled that they form a liquid tight seal between the thread. As the screws rotate, pockets/ cavities are formed where liquid gets trapped and conveyed from one end of the infinite stroke. This results in smooth, pulsation free flow with extremely low noise and vibration levels, almost impossible to be achieved by any other design of positive displacement or other types. The power rotor does not drive the idlers as commonly believed. The hydraulic forces acting on screw flanks turn the idlers torquelessly thus reducing the friction. The idlers simply roll over the root diameter of idler dia.reduce the unit pressure, centralize the power rotor and absorb the radial loads. A balance piston integrally machined on power rotor takes care of axial thrusts. While in operation, the screws are in hydrodynamic balance on film lubrication and do not require any additional bearings. The one ball bearing often used is only for axial positioning of rotor and safer operation of mechanical seals. Small rotor dimensions enable the pump to be operated at high speeds directly coupled 3000 or 3600 RPM motors or other prime movers. Such unique design and features has demonstrated excellent reliability with pumps in operation continuously non-stop for decades together without replacement of any components or maintenance on clean fluids. Typical Applications Fuel Oil Service: Fuel oil burner service for Thermal Power Plant/ Industrial Package, Boilers, Furnaces, Kilns and Combustion systems. Fuel transfer and booster service for Captive Diesel/ Gas Turbine Plants and Industrial Combustion Systems, Fuel Oil Circulations and Centrifuge Feeding. Tank farm tank to tank transfers. Hydraulic Duties: Hydraulic governing service for Water Turbines, Inlet Penstock Valves. Low and medium pressure hydraulic applications, high pressure jacking oil service for rotor lifting for Turbines/ Compressors/ Alternators. Lubricating Duty: Pressure lubrication and cooling of bearings for Turbo Machinery, Gear Boxes, Bearing Lubrication of Coal Mills, ID/FD Fans, Diesel Engines, Steel Rolling Mills, Air pre-heater guide bearings, Compressors. Seal Oil Service: Hydrogen cooled Generators, Gas and Refrigeration Compressors.

Color : Blue

Type : Three Spindle Screw Pump

Country of Origin : India

...more

strainer filters

10,000 - 100,000 Per Piece

Delta filtering equipments are installed in pipeline systems to remove unwanted particles

Brand Name : Delta PD Pumps

Material : Stainless Steel

Finishing : Polished

Shape : Square

Color : Blue

Condition : New

Power : 20Kw

Motor Power : 4HP

Operating Type : Semi Automatic

Usage : Industrial

Certification : ISO 9001:2008

Voltage : 110V

Packaging Type : Wooden Box

Particle Size : 200 Micron

Filtration Capacity : 50 Microns

Specialities : Hassle-Free Functioning

Flow Capacity Range : 100 Cfm

Type : Oil Filter

Diameter : 10 Inch

Country of Origin : India

...more

single screw pumps

10,000 - 200,000 Per Set

The pumping elements are rotor and stator. The single helical rotor rolls eccentrically in a double threaded helix stator of twice the pitch length. A series of sealed cavities 180° apart are created that appear to progress from suction to discharge during one rotation of rotor. The opposing cavities fill and empty simultaneously resulting in a pulsation less flow. The fluid travels axially with relatively low velocity and minimal agitation. The stator is made of a resilient elastomeric material and bonded to the stator tube. The important feature of the pumping principle is the ability to handle slurries and solid particles. The elastomeric stator also permits passage of solid particles due to elastomeric deformation.

Power Source : Electric

...more

Shuttle Block Pumps

10,000 - 200,000 Per rs

Brand Name : delta pd pumps

Application : Edible oil transfer.

Feature : Self priming.

Packaging Type : packed

Colour : blue

Type : shuttle block

Country of Origin : india

...more

Shuttle Block Pump

10,000 - 120,000 Per Piece

The Shuttle Block Pump works on a unique pumping principle - a combination of Rotary and Reciprocating action – Rotation of rotor causes reciprocating movement of shuttle and piston. There are only three pumping elements - ROTOR, PISTON and SHUTTLE. Rotor is keyed to a single shaft and runs concentric in pump casing.

Pressure : Up to 6 bar

...more

Screw Pumps

20,000 - 230,000 Per piece

Material : Carbon Steel, Cast Iron, Stainless Steel,iron

Driven Type : Electric

Color : Blue, Grey,blue

Power : 100-200kw, 200-300kw

Pressure : 1-50kg/cm2, 100-200kg/cm2, 400-500kg/cm2, 50-100kg/cm2

Type : Screw Pumps,screw

Fuel : Electricity

Structure : Horizontal

Country of Origin : India

Warrenty : service

Pump Speed : 100-1000RPM, 1000-2000RPM, 2000-3000RPM, 3000-4000RPM, 4000-5000RPM

...more

rotary twin gear pump

20,000 - 200,000 Per Piece

The geometry of the two rotors partitions the volume between them into N different dynamically-changing volumes. During the assembly's rotation cycle, each of these volumes changes continuously, so any given volume first increases, and then decreases.

Country of Origin : India

Type : Rotary Twin Gear Pump

Certification : ISO 9001:2008

Condition : New

Pressure : Upto 7 Bar

...more

rotary trochoidal pumps

10,000 - 150,000 Per rs

Applications : Lube Oil Transfer, Circulation

Condition : New

Pressure : 10-20Bar

Type : Rotary Gear Pump

...more

Rotary Trochoidal Gear Pump ( Series DRT/DRTBP )

12,000 - 50,000 Per rs

Only two rotating parts having principle of gear within gear but without crescent. The inner rotor is located off-center and both rotors rotate. The geometry of the two rotors partitions the volume between them into N different dynamically-changing volumes. During the assembly's rotation cycle, each of these volumes changes continuously, so any given volume first increases, and then decreases. An increase creates a vacuum. This vacuum creates suction, and hence, this part of the cycle is where the intake is located. As a volume decreases compression occurs. The Flow of liquid is axial through the elements. In built features of speed reduction as pinion is rotated at prime mover speed and outer gear rotates at lower speed. TYPICAL APPLICATIONS Transfer and Barrel unloading Pressure lubricating & cooling of bearings & gear boxes. Pumping, heating, cooling and filtering units. Pre-lubrication of components of machinery before starting. COST COMPARISON Very economical and costs fraction of screw pumps Power consumption is less than conventional pumps. Hence economical in operation.

Country of Origin : India

Type : Rotary Gear Pump

Certification : ISO 9001:2008

Application : Gear System

Condition : New

Automatic Grade : Manual

Pressure : 8 bar

Brand Name : delta pd pumps

...more

Retrofit Spares

1,000 - 20,000 Per rs

being a leading manufacturer of the entire range of positive displacement pumps, we understand the functionality of vital parts, materials and critical manufacturing tolerances. We guarantee that our parts will perform equal to or better than the originals and our satisfied clients are testimonial to this fact.

...more

pumping system

100,000 - 200,000 Per piece

The skids are engineered as per the specifications of customer, or Piping & Instrumentation Diagram provided by consultants and customers for all type of industrial use For Fuel Oils: For fuel oil unloading For fuel oil transfer For fuel oil injection in burners For fuel oil supply. For Lubricating and Hydraulics Oils: Jacking oil systems for Rotors of turbines and compressors Lubricating systems for fill lubrications Seal oil systems in power plants for turbo generators.

Power : 1-3kw

Packaging Type : Box

...more

Internal Gear Pumps ( Series DIG )

20,000 - 100,000 Per Piece

Delta DIG series employs proven Internal Gearing (Gear within Gear) principle for pumping. The main gear is keyed to the drive shaft, and rotates concentric in the pump casing. Idler is located on an eccentric pin on the front cover to rotate freely and meshes with main gear when assembled. A crescent shaped partition precision machined on the front cover maintains a small, but positive clearance to achieve perfect scaling between parts. As the gears come out of mesh, a partial vacuum is created, forcing the fluid to rush into the pump casing and fill in the voids between the teeth. Both gears rotating in the same direction of rotation gently transfer the fluid to the delivery port. The resulting action is a smooth-steady flow; low in pulsation, noise and vibration. Single shaft design well supported on outboard bearing (except for one inside sleeve bearing) enables to pump products even with poor lubricating value unlike in the external gear pumps. External bearing construction offers easy access the pump components i.e., rotor set and even pump casing simply by removing the front cover without disturbing drive parts, bearings etc., and in place. Block pump mounted integrally on hollow shaft gearbox automatically reduces the speed (in several ratios) and enables even the pump rotor to be pulled out without disturbing the drive! It is easily possible to jacket front and rear covers for products heating - thus making the design unique and versatile - ideally suited for process pumping.

...more

Internal Gear Pumps

10,000 - 100,000 Per Bag

1 Bag (MOQ)

The DIG series is modular developed with excellent interchangeability. The pump is available either as bracket mounted 'BM' or gearbox mounted 'GM" models.

Frequency : 50Hz

Country of Origin : India

...more

External Gear Pumps

20,000 - 300,000 Per Piece

External gear pump uses two identical gears rotating against each other -- one gear is driven by a motor and it in turn drives the other gear. Each gear is supported by a shaft with bearings on both sides of the gear. As the gears come out of mesh, they create expanding volume on the inlet side of the pump. Liquid flows into the cavity and is trapped by the gear teeth as they rotate.

Power : AC Powered

...more

External Gear Pump ( Series DG )

5,000 - 550,000 Per Rs

External gear pump uses two identical gears rotating against each other -- one gear is driven by a motor and it in turn drives the other gear. Each gear is supported by a shaft with bearings on both sides of the gear. As the gears come out of mesh, they create expanding volume on the inlet side of the pump. Liquid flows into the cavity and is trapped by the gear teeth as they rotate. Liquid travels around the interior of the casing in the pockets between the teeth and the casing -- it does not pass between the gears. Finally, the meshing of the gears forces liquid through the outlet port under pressure.

...moreBe first to Rate

Rate ThisOpening Hours