TGI 15 Diaphragm Vacuum Pump

3,500 Per Piece

1 Piece (MOQ)

SEAFLO Fresh Water Pump Diaphragm Pumps 12V / 24V 17LPM 17-60PSI

5,500 - 5,501 Per Piece

1 Piece (MOQ)

The 41-Series pump provides high volume water flow with reduced pump cycling, thanks to the quad?chamber diaphragm and internal bypass. These models are designed to run on water systems with no accumulator tank necessary, and up to five outlets. It is also suited for use with a holding tank water system, as may be found in a boat, RV or remote cabin. It provides up to 4.5 gallons per minute, suitable in a system of up to five fixtures. The 41-Series pumps are self-priming, and can run dry without damage, performance reliable and low current.This automatic demand water system pump has a built-in pressure switch, which automatically starts and stops the pump when faucet is opened and closed.They're easy to install service and winterize with quick snap-in port fittings.

Best Deals from Diaphragm Pump

GilAir 5 Air Sampling Pump

Get Price Quote

GilAir-5 Air Sampling Systems offer both high and low flow sampling capabilities. These capabilities range from 1cc to 3,000cc and 1cc to 5,000cc respectively. GilAir-5 samplers consist of an electronic control system, a pneumatic system, and a rechargeable battery pack. GilAir-5 sampler is equipped with a basic control board, which contains the flow control circuitry. The board also contains the On/Off switch, flow control potentiometer, flow fault indicator, and battery charge indicator. Features External Filter Housing Flow Fault And Test Indicators Basic, Clock & Program Models Optional Low Flow Modules Flow Rate 1- 5000 cc/min (Total), 850 - 5000 cc/min (High Flow); 5-500 cc/min (Constant Low Flow); 1-750 cc/min (Constant Pressure)

PVDF (Injection-Molded) And PTFE Lined Back Pull Out Pumps

Get Price Quote

We LEAKLESS (INDIA) ENGINEERING are leading manufacturer and exporter Of LCP Series PVDF (Injection-Molded) And PTFE Lined Back Pull Out Pumps , specially designed for highly corrosive liquids and high temperature applications. These types of pumps deliver outstanding performance with economical prices .The range being easy in use and demands minimum maintenance. Pumps offer thick injection molded casing with C.I Or S.S casing liner insert for strength of casing with easy replaceable method. Semi open (Injection-Molded) Impeller with metal insert. Excellent mechanical properties over a wide range of temperatures up to 150º C. Material Of Construction POLYVINYLIDENE FLUORIDE (PVDF) POLYTETRAFLUOROETHYLENE (PTFE) Applications And Industries Served CHEMICAL PROCESS UPTO 150OC ORGANIC/IN ORGANIC CHEMICAL HIGHLY CORROSIVE ACID TRANSFER AIR CONDITIONING EFFLUENT ELECTRO PLATING HIGHLY CORROSIVE ACID TRANSFER DYES AND PIGMENTS SCRUBBER UNIT WATER TREATMENT SOLVENTS UNLOADING TRANSFER OF LIQUID

TID 45 FM Diaphragm Vacuum Pump & Compressor

Get Price Quote

1 Piece (MOQ)

mechanical pump

Get Price Quote

Details : Mechanical pumps serve in a wide range of applications such as pumping water from wells, aquarium filtering, pond filtering and aeration, in the car industry for water-cooling and fuel injection, in the energy industry for pumping oil and natural gas or for operating cooling towers. In the medical industry, pumps are used for biochemical processes in developing and manufacturing medicine, and as artificial replacements for body parts, in particular the artificial heart and penile prosthesis.

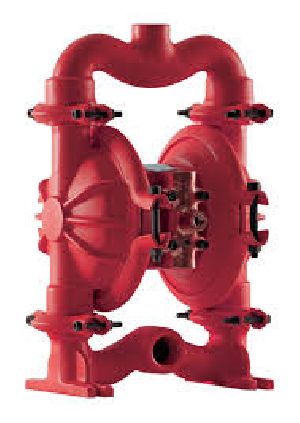

Double Diaphragm Pumps

Get Price Quote

Air operated diaphragm pumps are reciprocating pumps where the working elements are flexible diaphragms. The drive is by means of compressed air acting directly upon the diaphragm. Another possibility is hydraulically drive instead of compressed air. At least two valves, one on the discharge and one on the suction side, are necessary. Several types of valves are used. The most popular valves are flap, cylindrical and ball valves. Air-operated double diaphragm pump is a self promised pump to work hard against huge number of Liquids and atmosphere , donate driver seat to user.

Electric Double Diaphragm Pump

Get Price Quote

Specifications Max Flow Rate586Lpm (155gpm)Port SizeInlet : 50.80mm (2" BSP)Discharge : 50.80mm (2" BSP)Air Inlet : 12.70mm (12" BSP)Air Exhaust : 19.05mm (34" BSP)Suction LiftDry : 4.57m (15')Wet : 7.62m (25')TeflonDry : 3.05m (10')Wet : 6.09m (20')Max Particle Size (Dia)6.35mm (0.250")

Air Operated Diaphragm Pump

Get Price Quote

double diaphragm pump

Get Price Quote

To handle viscous chemicals,slurries To transfer explosive liquids,solvents,acids. Pharmaceutical liquids creams and compounds. Semi solid foods, flavours, drinks, wine, beer, alchohols. Waste water, sewage effluents, coal and lime slurry. Hydrocarbons, petrol diesel, lubrication oil, vegetable oil. Paints emulsions,pigments, thinners, resins. Ceramics, Slip Gazes, Clays.

Metallic and non metallic teflon lined pumps

10,000 - 200,000 Per Inr

1 Piece (MOQ)

MANUFActurer of centrifugal teflon lined pumps

Liquid Ring Vacuum Pump

Get Price Quote

We work with an aim of fulfilling variegated requirements of the clients. And, for this, we have developed a large facility wherein we keep our products. Buyers across Bhiwandi(India) and other markets can contact us for purchasing our product all year round. Salient Features: No Lubrication required Noiseless performance Absolutely Portable Totally Oil-free construction Practically maintenance free Built-in micro suction filter Special diaphragms available (Teflon / vi-ton etc.) Extra large bearings for trouble - free and smooth running Pump available with flameproof motor Pump available with chemical resistive parts (PP / PVC / Teflon / SS contact parts) Pump available for gas charging in Air conditioners Motors available in 110 V AC also Ideally suited for original equipment manufacturers

Diaphragm Pump

Get Price Quote

Diaphragm Type Vacuum Pump

Get Price Quote

We are manufacturer of single double stage diaphragm type vacuum pump.

Air-Operated Grease and Oil Pump

Get Price Quote

Mini Fire-Ball 225 Air-Operated Grease and Oil PumpPerfect for medium pressure, low volume applications You can't afford down time, espeically when your shop is small and your work force depends on equipment performance. The Mini Fire-Ball 225 is an engineered design with fewer moving parts, which means less wear out, and reduced downtime and more profit for your business. Available in 3:1 for oil and 50:1 for grease.Features:50:1 ratio allows grease to be pumped up to NLGI #2Available for 35 lb (16 kg), 120 lb (55 kg) and 400 lb (180 kg) containers3:1 ratio for petroleum and synthetic-based oilsDouble acting pump provides continous flow operationRugged inlet cage withstands demanding shop environmentsFull line of stationary and portable package configurationsMaterial:Motor OilGear OilHydraulic FluidAutomatic Transmission FluidOilGreaseApplications:LubricationOil TransferGrease TransferPumpingFluid TransferIndustries:Agriculture Equipment - MaintenanceMining Equipment - MaintenanceForestry EquipmentPaper MillsDealerships and Quick Lubes - Pumps

aodd pump

Get Price Quote

Air Operated Double Diaphragm Pump

Get Price Quote

We offer superlative quality Air Operated Double Diaphragm Pump that is highly efficient. The Air Operated Double Diaphragm Pump is manufactured using high grade raw materials. We are regarded as one of the principal Air Operated Double Diaphragm Pump Manufacturers and Suppliers in India. It can be availed at highly affordable rates. Features : Self PrimingCorrosive and Slurries can be easily managedVariable speedProcess fluid must be compatible with material of constructionTeryair diaphragm pumps can be stopped by simply switching off the discharge valveEasy operation and maintenance Uses : Widely used to pump liquid with solid particles and high viscosity liquidThey can be used in positive and negative suction situations

Diaphragm Type Metering Pump

Get Price Quote

1 Piece (MOQ)

JAKIM PUMPS Manufacturers of Hydraulically Operated Diaphragm Type Metering / Dosing pump for suitable service conditions involving hazardous toxic, radioactive or poisonous liquid where product leakage is not at all permitted. The Diaphragm is hydraulically actuated and has a long life as it is always in hydraulic balance, with the liquids being pumped on one side and actuating fluid on the opposite side. Its function is basically that of a partition. The diaphragm material is usually Teflon. The system is safety guarded by a in built Relief Vacuum Combancity Valve on the hydraulic side. For very severe duty conditions or when handling slurry or hot liquids, double diaphragm and remote heads can be provided.The Range includes high precision positive displacement pump conforming to API 675. Typical applications for our pumps are useful for accurate dosing and mixing of acids, alcoholics, slurries, viscous liquids etc. Our range covers everything from the single pump to a completed automated Metering dosing system and comprises of plunger and diaphragm pump with metering range from various capacity and pressure from 2 – 15000 LPH. pump can be offered in Simplex, Duplex, Triplex and Multiple Heads, handling for different chemicals with a common Motor. Each head would have independent connection and capacity of each head can be also independently adjustable.The pump discharge is variable while pump is running or at rest from Zero (0%) to full stroke (100%) by means of a precision machined Crank equipped with a stroke length adjustment mechanism. The Stroke of the pump controlled either Manually Wetted parts can be offered in S.S. 316 or 304, Carbon Steel, P.P. / Teflon / PVDF, Alloy 20, Hastalloy B or C. etc.Double Diaphragm Pump : It has a Diaphragm Rupture Indicator, which indicates if the Diaphragm gets damagedApplicationsDiaphragm Type Pumps are used in Chemicals Plant, Fertilizer Plant, Water Treatment Plant, Soap Plant, Paper Industries, Pharmaceuticals Industries, Thermal Power Projects, and Plastic Industries.

Liquid Ring Vacuum Pump

Get Price Quote

We offer liquid ring vacuum pump.

air operated diaphragm pumps

Get Price Quote

1 Piece (MOQ)