Pressure Die Casting

Get Price Quote

Aluminium Pressure Die Casting

Get Price Quote

The IP66 waterproof aluminium junction box by BBOX enclosures is ideal for electronics and automotive applications, providing robust protection.

Best Deals from Pressure Die Casting

LED PRESSURE DIE CASTING

Get Price Quote

we take this opportunity to introduce ourselves as a leading mould manufacturer, having presently a well-equipped precision tool room, which can cater to undertake design, development and manufacturing of various industrial plastic moulds, bakelite moulds, jig & fixtures, pressure die casting ,blow mould , street lighting , diffsuer ,impiller mould, automobiles part and tooling for industries.

Aluminium Pressure Die Castings

Get Price Quote

Our Aluminium Pressure Die Castings are used for general engineering and automobile applications as per required design and specification by the customer. We are successful Suppliers and Exporters of Aluminium Pressure Die Castings from India. Aluminium Pressure Die Castings reduce or eliminate the need for secondary machining operations. Our Aluminium Pressure Die Castings have excellent dimensional accuracy, casting of low fluidity metals and smooth cast surfaces.Key Features : Excellent dimensional accuracy Smooth cast surfaces Thinner walls can be cast as compared to sand and permanent mold casting Inserts can be cast-in (such as threaded inserts, heating elements, and high strength bearing surfaces). Reduces or eliminates secondary machining operations. Rapid production rates. Casting of low fluidity metals.

PDC-004 Pressure Die Casting

Get Price Quote

Pressure Die Casting

Zinc Pressure Die Casting

Get Price Quote

We undertake development of Customized Parts in sand castings, pressure die castings aluminum or zinc, forgings various steels by processes such as hammer forgings or press forgings. We also undertake development of plastic injection moldings. Alternately we also supply tools, dies and moulds for customized part as per the drawings or samples provided by the customers.

Pressure Die Casting

Get Price Quote

MAKE IDRA BULLER MODEL UNKNOWN CONTROL CONVENTIONAL LOCATION NEW DELHI COUNTRY OF ORGIN ITALY TIME OF DELIVERY IMMEDIATELY AGAINST PAYMENT YEAR OF MANUFACTURING UNKNOWN OCKING FORCE 160 TON INJECTION FORCE 20 TON EJECTOR FORCE 12 TON EJECTOR STROKE 100MM MIN./MAX.DIE HEIGHT 150/550MM PLATEN DIMENSION HXV 675X675MM DISTANCE BETWEEN TIE BAR 435X435MM TIE BAR DIAMETER 75MM DIE OPENING STROKE 450MM INJECTION PLUNGER STROKE 300MM INJECTION POSITIONS 0 / -50 / -100 / -

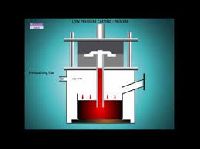

low pressure die casting

Get Price Quote

n die casting, molten metal is injected into a mold at high pressure. The pressure can range from about 1,400 psi to as high as 30,000 psi. By pressurizing the mold, the cast object will be more uniform and will display an attractive finish. In many cases very little or no post-casting machining is needed to complete the item. Pressure molding also provides for precise dimensional accuracy that is critical for parts used in products with interchangeable parts. Low pressure die casting is commonly used for larger non-critical parts. Whereas high pressure castings which are used for tight tolerance detailed geometry. High pressure die castings are able to maintain tighter tolerances and more detail than low pressure die casting because the extra pressure utilized is able to push the metal into more detailed features in the mold. High Pressure die castings have excellent surface finishes that are consistent dimensionally with precision features and minimum draft. There are two main die casting processes, and their use is dependent on the type of metal being cast:

Pressure Die Castings

Get Price Quote

Pressure die castings are one of the most exclusive quality equipments which we are manufacturing and supplying to our clients in almost each and every region of the country. These pressure die castings are used for the purpose of providing the outer covering and sturdy body for the halogen lights for various outdoor purposes. These pressure die castings have been designed in an excellent manner using top grade raw materials which make them strong and efficient to withstand every climatic condition.

Pressure Die Casting

Get Price Quote

We are the leading service providers for Pressure Die Casting. Our Pressure Die Casting services are reliable and are extremely popular among clients. We offer our Pressure Die Casting services at the market leading prices. The services we offer are effective and are designed keeping the work requirements of the clients in mind. We have the advanced machines and tools to carry out superior quality Pressure Die Casting process. Our team is skilled and experienced in this area which enables us offer high standard Pressure Die Casting services. Description It involves a process of melting the metal and compelling them into steel diesAfter hardening, the metal takes the desired shapeThe movement of a plunger controls the processThe plunger reverses direction after the solidification time and ejects the part and gets ready for the successive cycle Types of Pressure Die Casting Hot chamber casting The plunger forces a preset quantity of molten metal into the die cavity. This process is used for zinc, copper, magnesium and lead which have low melting points.Cold chamber casting Molten metal is introduced into the injection cylinder and is forced into the cavity at high pressures. Aluminum and copper have high melting points and so are suitable for this process. Advantages Creates parts with no joints by eliminating other processes such as welding and fasteningIntegral fastening elements can be includedDimensional accuracyDoes not require more machine operationsReduced costCapable of producing a wide variety of complex 3D shapes Used for Machine components ToysEngine parts Industries Automobile IndustriesAerospaceMedical Nonferrous alloys that have low melting points are processed with this technique. Such as AluminumZincMagnesiumCopperLeadTinSilver

low pressure die casting

Get Price Quote

low pressure die casting, Plastic Moulds, high pressure die casting

precision pressure die casting

Get Price Quote

precision pressure die casting, customized pressure die casting

Zinc Pressure Die Casting

Get Price Quote

Zinc Pressure Die Casting, Aluminium Gravity Die Casting

Pressure Die Casting

Get Price Quote

Pressure Die Casting, plastic injection components, Limit Switch Box

pressure gravity die castings

Get Price Quote

pressure gravity die castings, Strategic sourcing, Global Sourcing

Pressure Die Castings

Get Price Quote

Pressure Die Castings, bakelite mouldings, Dies, mouldings

Pressure Die Casting

Get Price Quote

Pressure Die Casting, Industrial Plastic, house hold plastic

high pressure die casting

Get Price Quote

high pressure die casting, fuel tank dies, panel dies, Gravity die casting

Pressure Die Casting

Get Price Quote

Pressure Die Casting, Industrial Products, tool room service

Pressure Die Casting

Get Price Quote

Pressure Die Casting