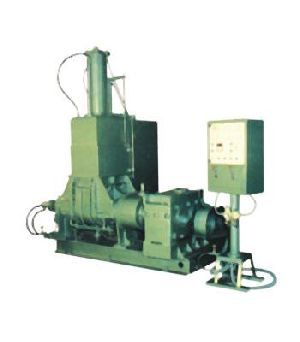

Dispersion Kneader

Get Price Quote

Dispersions kneader for the mastication of rubber batches. Built with high precision, the machine delivers thoroughly dispersed compounds, with help of correctly angled blades offering best shearing action. A uniformly downward-acting , contoured , cooled pressure-lid, and jacketed-mixing area ensures even mixing. The self-cleaning mixing chamber is duly polished and hard chrome plated, adding a best service life to the machine With an adjustable tilting angle ( max. 140), equipped with a temp. Probe , and mixing timers, the machine is highly user friendly. The electric panels supplied are thoroughly engineered, and are ergonomically designed.

Dispersion Kneader

Get Price Quote

We are instrumental in offering a high quality range of Dispersion Kneaders to the esteemed clients in various ranges & specifications. We offer complete series of kneaders from lab to 120 Litres production model in Rear change and front discharge type with hard faced rotors and chambers for longer life.These products are widely used for rubber processing and plastic industries, thus, are highly demanded by the clients. Equipped with automatic time and temperature control system, Dispersion Kneaders are known for providing cent percent mixing effect. The peculiar jacket construction of these Dispersion Kneaders generates cooling effect and low temperature mixing of the rubber compounds. Our Rubber Kneader machines are used in wide range of industries. These Rubber kneaders machines are versatile and can operate at high temperatures. G.G. Engineering Works manufactures world class dispersion kneader, rubber kneader machine. With simple operation and easy cleaning, it gives its best even when the operator's skill and experience are limited. A dispersion kneader superior by design, engineering and construction represents an advanced class of kneaders in India. MIXING CHAMBER : Alloy Steel, Fabricated Hard faced, jacketted (both logitudinal & transverse) for steam heating & water cooling. Capable of Tilting to Approx, 130° for eay discharge & cleaning. MIXING ROTORS : Made of alloy cast-steel, spirally anullar design, with node tips i nternally cored for effective Tempretaure Control.The Land of the nodes are hard & profile ground. PRESSURE LID : Steel fabricated hard faced at mixing contact area, Jacketted for effective heating / cooling. GG 55 LITRE KNEADER (TILT METHOD-HYDRAULIC) DUST SEALS : Specially wet / dry type designed to keep environment Cleanliness & are easily replaceable.DUST EXHAUSTING DEVICE : Hovering Vapours / dust, absorbed by ducting to dust collector.Tilting to Approx, 130° for eay discharge & cleaning. SEQUENCE CONTROL : Either Manual or Automatic by electrical Control panel with P.L.C. timer based system as an optional feature.TEMPERATURE INDICATION CONTROL : Temp. Indicators with Thermoprobes giving the exact mix tempretuare. Automatic Tempretuare control device with forced water pump & contact thermometer can be provide as an optional feature.

Best Deals from Dispersion Kneader

Dispersion Kneader

Get Price Quote

Dispersion Kneader, Vaccume Moulding Press, Hot Feed Rubber Extruding Machine

Rubber Dispersion Kneader

Get Price Quote

Rubber Dispersion Kneader, Rubber Processing Machine, Rubber Mixing Mill

dispersion kneader & spares

Get Price Quote

dispersion kneader & spares, Hydraulic Presses, industrial rubber extruder

Dispersion Kneader

Get Price Quote

Dispersion Kneader, Bucket Conveyor, Rubber Bale Cutter, Auto Clave