Water Distillation Unit

Get Price Quote

Multi Column Distillation Plant

Get Price Quote

1 Plant (MOQ)

Best Deals from Distillation Units

Distillation Column

Get Price Quote

A DISTILLATION COLUMN is an essential item used in distillation of liquid mixtures so as to separate the mixture into its component parts, or fractions, based on the differences in volatilities. Fractionating columns are used in small scale laboratory distillations as well as for large-scale industrial distillations.Material of Construction (MOC) Offered :- CS (IS 2062 Gr A/B, SA 516 Gr 60/70, BQ), SS 316, SS 304, SS 316 L, SS 304 L. SS 310, MONEL, INCONEL, TITANIUM, HASTALLOY, ETC.

Distillation Columns

Get Price Quote

We are a client centric organization which is engaged in offering Distillation Columns. They are cherished by our customers all over the world. The quality is ensured to be in concurrence with the standards and norms set by the industry. We make them available in a number of specifications and customizations. Their easy installation, smooth operation and zero maintenance make them a popular choice. Details : Distillation is the most widely used separation process in the chemical industry. It is also known as fractional distillation or fractionation. It is normally used to separate liquid mixtures into two or more vapor or liquid products with different compositions.Columns are mass transfer units generally used for the following applications : Distillation Gas Absorption Solvent Extraction Packed Column etc

Industrial Chemical Recovery Unit

345,000 Per Piece

1 Piece (MOQ)

Double Glass Distillation Unit

52,960 - 93,520 Per Unit

1 Piece (MOQ)

Multi Column Distillation Plant

Get Price Quote

1 Piece (MOQ)

columns

100,000 - 5,000,000 Per Piece

1 Piece (MOQ)

Stainless Steel columns used in chemcial plants and process industries

solvent distillation

Get Price Quote

Solvent distillation best equipped distillation unit we could provide you purification of your product with best yield.All Non Moving material.

Reactive Distillation Unit

100,000 - 1,500,000 Per Piece

1 Piece (MOQ)

The unit has been designed to suit the customers requirement of combination of versatile reaction / distillation or combination for pilot plant work. This has a flexibility of working at atmospheric pressure as well as under vacuum. Typical unit has a reaction vessel fitted in a metal heating/cooling bath having facility for heating and cooling bath by means of heating/cooling Fluids as a media. The Standard system is equipped with stirrer heaving mechanical seal, a packed column on the side neck of the vessel, reflux divider, coil type condenser and or receiver system having a product, cooler, vent, drain and vacuum valves, Option of speed variation by machanical variator or electronic variator can be provided. Receiver system is equipped with product cooler. Vent / vaccum valve and drain valve. The above unit are available in 10 Ltr., 20 Ltr., 50Ltr.,100 Ltr., 200 Ltr. & 300Ltr capacity with spherical reactor.

Solvent Recovery Unit

Get Price Quote

A cost effective system for recovery of >99% pure solvent from mother liquors consisting of moisture, dissolved solids, chemical residues, etc. * provided on design equipment supply turnkey basis * capacity of 200 lph to 2000 lph of solvent working successfully * recovery units provided for solvents such as methanol, acetone, acetic acid, etc.

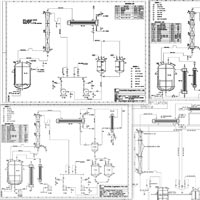

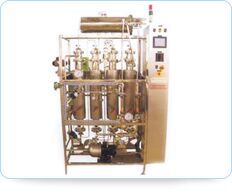

multicolumn distillation plant

Get Price Quote

multicolumn distilled water plant designed to produce 100% pyrogen free sterile distillate & chemically pure confirms to IPBPUSP standard. Multicolumn distilled water plant works on the principle of interstate heat exchanger, dramatically reduce the consumption of heating energy and cooling water. Thus enable to produce a large volume of pyrogen free distillate at a fraction of the cost than conventional systems. All documents related to factory acceptance test(FAT), Installation Qualifications(IQ), Operation Qualification(OQ), PQ are provided as part of the operational manual.

distillation towers

10,000 - 500,000 Per Ton

1 Short Ton (MOQ)

Distillation Column, Distillation Towers, Process Equipments Price : INR 10000 - 500000 -per- Ton

Fatty Acid Distillation Plants

Get Price Quote

1 Piece (MOQ)

Distillation Columns

Get Price Quote

Distillation columns have generalized its deep knowledge and experience of their in-house professional engineers and offers a premise of building an excellent class of Distillation Column design that are utilized worldwide. Our made distillation columns have various unique features as compared to conventional types of columns. We bring various types of distillation column system in the market. There are various reasons that affects the function of the column like conditions of feed, its components, internal fluid and its flow conditions. Distillation columns are used in small scale laboratories as well as in big manufacturing types of industries.

Distillation System

Get Price Quote

Distillation System is an effective technique of separating mixtures and entirely a physical separation process. It is generally used in a numerous types of applications. It is said that distillation entirely depends on the boiling point of the substance and the one who has very low boiling point will suit for the best as vapors will be richer in such components. When these vapors are cooled, the condensate contains much more volatile contents than the original mixture. It is also true that their efficiency can be increased through optimization.

Water Still Distillation Unit

Get Price Quote

All Glass water still All glass water distillation is a unique & intelligent water distillation unit.The heating element is ceramic bobbin heater with Nichrome heating wire. The distillates of unit have very low conductivity(less than 1 mho).The company has two model viz, 1.5lt/hr distillation water output for continuous run & 4.5 liters/hr capacity. Added Feature : The unit has unique feature for automatic water level maintain by solid -state device.It gives audible alarm when the water level is sufficient.Both the unit comes in 3phase/single phase electrical poer supply model.The whole unit of the system is made of stainless steel. The unit is totally hassle & maintenance free with intelligent & user Friendly. Water Still Condenser Opening type : These electrically operated water stills have been scientifically designed to ensure economy in operation and beyond occasional cleaning they do not require any special attention. Complete body and condenser tube is made of stainless steel .A triple vapor baffles provided to avoid splashing of water into delivery tube.The lid is automatically sealed by recess in the head of the still into which the flange of the lid rests.The minimizes the loss of steam.The water supplied to the still through the constant level arrangement also serves to condense the steam in the condenser. The condenser tube can be dismantled without any difficulty, by removing the wing nuts which hold the end condenser jacket together.Removing the lid exposes the evaporating vessel. The still is fitted with immersion type elements,which are capable of displacing the connectors, if the still runs dry. The still is provided with provided with a bucket(to be fixed on a wall) on which it can rest.

Sieve Trays

Get Price Quote

Sieve Trays consists of flat perforated deck. Passage for the vapours is through holes provided. The vapour pressure is such that it prevents liquid into the perforation. These trays have good capacity and moderate efficiency. Sieve Trays have low maintenance cost.

Water Distillation Unit

Get Price Quote

Distillation removes organics impurities, as well as colloidal solid from water. Borosil glass distillation unit continue to be the most effective and economical method of producing pure water for laboratory use. By contrast dye lasers are effective on;y in removing those substance that are ionized moreover, the resins contribute organic impurities to water resulting in an environment conducive to bacterial growth in course of time. Borosil distillation unit are designed to produce a distillate of considered purity. the unit of horizontal borosilicate boiler, condenser and a quartz heater. All the parts are replaceable.

Distillation Column

Get Price Quote

We are offering distillation column, aries engineers is a leading manufacturer of distillation columns and evaporators. We supply a wide range of materials and diameters to suit each process requirement. We also check on the design considerations, such as seismic and wind load conditions, at the precise location where the utensils is to be installed. Our knowledge includes the use of many different types of column internals. Consider us when looking for columns and evaporators. our range of distillation columns suggest high efficiency and are designed for effective distillation process. Our distillation columns are available for customization. Designed to deliver desired results in the separation of liquids.

Industrial Distillation Column

Get Price Quote

In order to meet the variegated demands of the clients, we have come up with a wide range of Distillation Column. With the help of our dedicated team of professionals and sophisticated infrastructure, we design all the products as per the international quality parameters. All the products are rigorously examined by our quality controllers team to ensure their flawlessness. In addition to this, we are offering these products in varied designs, sizes, and specifications as per the exact requirements of our esteemed clients.

Water Distillation Unit

Get Price Quote

We are a reputed Manufacturer, Exporter & Supplier of Water Distillation Unit. The Water Distillation Unit is commonly used in biological labs, clinical research labs, R&D labs, hospitals, etc. to produce pyrogen free distilled water. The Water Distillation Unit is designed with complete precision. The Water Distillation Unit is known for its durability, efficient performance, high functionality and excellent strength. Construction And Working The unit is wall-mounting with the full Body made up of stainless steel fitted with ISI certified safety ejection type immersion heaters. A constant water level arrangement is provided. A steam baffle is provided to take steam direct to thecold-water jacketed condenser. The stated output of the still is approximate as it is bound to vary according to the voltage of the MAINS. An electronic watch dog water level system with auto heater cut-off when water level is low along with buzzer can be provided at extra cost. Power Supply: 230 V, 50 Hz. Note: It is advisable to use DM water as i/p to the still, to ensure long duration of heater life Conductivity of o/p distilled water: ¡� 3 micro-mho. Optional : Electronic solid-state water-level watch-dog circuit with buzzer alarm and heater cut-off Price : Rs. 3,000.00 extra

Distillation Equipment

Get Price Quote

Short Path Distillation Unit Operating principle of short path distillation unit (SPDU) is similar to thin film except internal condenser. Here internal condenser is installed inside rotor cage assembly. The feed enters the unit at top and get distributed into a thin film on the inside surface of shell. Heating medium passing through the jacket evaporates volatile component in feed. The vapor generated flow across the rotor and condense on internal condenser. This short path of vapor eliminate pressure drop. hence evaporation can be done at high vacuum as 0.001 mbar. The distilled product and balance bottoms are taken out through separate outlets.

Multi Column Distillation Plant

Get Price Quote

Multi Column Distillation Plant available from 80 ltrs. hr. to 1500 ltrs. hr. capacity produces 100% pure, pyrogen free, sterile distillate at unmatched low operational cost which confirms to Pharmacopoeia standards for WFI. All contact parts are made out of S.S. 316316L and all the tubes are seamless. The system works on the principle of inter stage heat exchange and use intrinsic heat to supplement consumption need of heating energy and cooling water. Due to surface film evaporation

Continuous Distillation Columns

95,000 Per Piece

1 Piece(s) (MOQ)

Custom manufacturer and supplier of continuous distillation columns. Biotechnology, pharmaceutical, chemical, lamp working, lighting, architectural, laboratory and testing industries served. On-time delivery.

Multi Column Distillation Plant

1,000,000 Per Piece

Distillation Column

Get Price Quote

A Distillation Column is an indispensable item used in distillation of liquid mixtures so as to separate the mixture into its component parts, or fractions, based on the differences in volatilities. We are a noted Distillation Column Manufacturer, Exporter and Supplier in Maharashtra (India). As per the industrial set norms and standards, we manufacture our Distillation Column using the best grade materials of construction and latest technology. We can customize our product as per the specifications and dimensions provided by our customers. Also, they are available at very affordable prices. Details : Material of Construction (MOC) Offered : CS (IS 2062 Gr A/B, SA 516 Gr 60/70, BQ), SS 316, SS 304, SS 316 L, SS 304 L. SS 310, Monel, Inconel, Titanium, Hastalloy, etc. Fractionating columns are used in small scale laboratory distillations as well as for large-scale industrial distillations

Steam Distillation Unit

Get Price Quote

To Isolate & derive steam volatile essential oil from various herbs / leaves/ stems / twigs / bark/ roots. Capacity :50 Ltrs. To 10,000 Ltrs. Salient Features : Easy loading & unloading facility incorporated to accomplish the entire operation comfortably. Appropriate facility provided for hydro distillation of various essential oils. Unit is designed to accomplish preconditioning of feed material under auto pressure. All safely devises are incorporated. Unique design of separators facilitates efficient separation of aqueous phase from the heavy as well as light essential oil. All fixture / accessories of standard make provided to facilitate monitoring & measuring steam inputs temperature and pressures. The entire assembly is provided with easily assemble able steel structure and internal piping. MULTIPURPOSE SOLVENT EXTRACTION UNIT FUNCTION To extract all kinds of natural material by various solvents/ water adopting techniques such as. Soxlet Cold Percolation Hot Percolation Capacity :50 Ltrs. To 10,000 Ltrs Salient Features : Multipurpose design. Facility provided to load and unload the material to be extracted easily. Reboiler provided with mechanical agitation to avoid localized heating of the extract at any given time . On line filters provided to obtain a sparking clear extract. Adequate condenser and subcooler capacity provided to minimize losses of solvent. Vacuum traps provided to facilitate recovery of solvent under reduced pressure without much evaporation loss. Pressure balancing tanks / vacating tanks provided to facilitate recovery of solvent from the extract. Entire unit is explosion proof having flame arrester attached wherever necessary. All pipelines, valves, fixtures are colour coded for easy identification and fixed at handy locations to facilitate easy operation. Sampling points provided to facilitate on line analysis. The unit is provided with all standard best available valves / gauges / fixtures sensors and instruments. Complete Unit along with easily assemblable steel structure is offered. All welded joints/finish as per internation standards. Operating manual provided with the unit. View glasses provided to have a visual inspection of the ongoing batch.

Multi Column Distillation Plant

Get Price Quote

multi column distillation plant designed based on finn-aqua which produces pyrogen-free sterile water for injection (wfi) which meets the requirement of ipbpusp .. The vapors with high velocity and under pressure passes over a SPECIALLY DESIGNED SPIRAL BAFFLE which develops tremendous centrifugal force and thus eliminates any chances of pyrogens carry over in the vapors. The columns, heat-exchanger, feed pumps, valves & instruments, control panel will be mounted on ss tubular structure.

Multi Column Distillation Plant

Get Price Quote

Multi Column Distillation Plant is based on FINN-AQUA design. It consists of expressly designed columns which make best use of the principles of interstate heat exchange (Multi effect distillation method) to generate pure pyrogen free sterile distilled water for injectables as per IPBP specification. The vapours with high velocity and under pressure passes over a SPECIALLY DESIGNED SPIRAL BAFFLE system which develops remarkable centrifugal force and thus eradicate any chances of pyrogens carry over in the vapours.