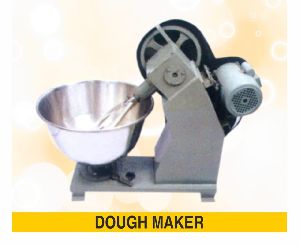

Dough Kneading Machine

Get Price Quote

Matching to the requirements of the customers, we are involved in offering best quality of dough kneading machine. The offered products are easy to use. We ensure to mete the customers requirements. Clients can purchase our products at reasonable rates. Further, the offered dough kneading machine is extensively used for making besan dough for namkeens and as well as for mixing the ingredients. Our material is very good in market.

Dough Kneader

12,499 - 85,000 Per piece

1 Piece (MOQ)

Best Deals from Dough Mixers

Planetary mixer

Get Price Quote

We are offering planetary mixer

kneading machine

Get Price Quote

1 Piece (MOQ)

Planetary mixer

Get Price Quote

The Planetary mixer machine is basically mixing assembly wherein the agitation pattern is of a planetary nature. If offers optimum output as these are installed with gearbox, variable speeds with electronic control. Further, our range can be customized as required by our clients. The blade movement and up-down movement is done through hydraulic system, so that electrical contact is avoided. CCTV is provided to see the operation in remote working PLC along with SCADA operates the full system from a safe distance.For the processing of sensitive & hazardous heterogeneous compositions containing low to medium viscosity resins/binders & various dried particulate fillers having different particle size ( less than 1 micron to 300 micron) under high vacuum. Intimate mixing of these ingredients is must to ensure uniform mix. End of Mix viscosity to these compositions may vary from 50 poises to 80000 poises at 25°C. For removal of moisture & occluded gas / air from high viscosity composition, application of high vacuum of 0.1 mm of Hg is necessary during mixing. For very viscous compositions initial circulation of hot water through mixer jacket is essential and to avoid sudden rise in viscosity after addition of curing agents cold water circulation through jacket is required. The Planetary mixer unit consist of a Mixer, bowl with trolley, hydraulic drive unit, remotely operated control system with PLC & SCADA along with power back up system for PLC & close circuit camera & color Monitor for remote viewing, during Mixer Operation.We offer wide range of planetary mixers for Defense industry which are manufactured in different specifications and capacities. With excellent deaeration, these planetary mixers prevent the paste from becoming lumpy. With robust construction and durability, these planetary mixers are widely used for mixing, degassing and kneading viscous and heat sensitive pastes. We also offer tailor made requirements. The speed of planetary mixers ranges from 1rpm to 100 rpm. We can obtain products containing solids Upto 85% in the final mixture.Material of Construction (MOC) Offered : - CS (IS 2062 Gr A/B, SA 516 Gr 60/70, BQ), SS 316, SS 304, SS 316 L, SS 304 L. SS 310, MONEL, INCONEL, TITANIUM, HASTALLOY, ETC.

Commercial Dough Kneading Machine

16,500 - 48,500 Per piece

1 Piece (MOQ)

Frozen Samosa Dough Sheet

80 Per Packets

30 Packets (MOQ)

Gharelu Atta Dough Making Machine

7,650 Per Piece

1 Piece (MOQ)

Berjaya BM 20N Planetary Mixer

63,999 Per Piece

3 Piece (MOQ)

Dough Mixer

Get Price Quote

We have state-of-the-art warehouse that is well-maintained by the storage experts. They ensure that our wide array of products is kept safe before making the final dispatch. In order to settle the financial transaction with our clients through the transfer of monetary value, we offer diverse options including online and offline payment procedures.

Pizza Dough Roller

98,000 Per Piece

1 Piece (MOQ)

Planetary mixer

152,600 - 697,000 Per per unit

1 piece (MOQ)

special features: * all contact parts s.s. 316 quality material * product bowl mounted on castor wheels for easy portability. washing & transporting mixed materials. * motorized drive assembly for lifting & lowering. * needs comparatively smaller area for installation. * electrical control panel with backup fuses and indicator lamps for easy process control of different products. we have model 10 lts to 1500 lts capacity

Planetary mixer

Get Price Quote

Planetary Mixer is ideal for mixing of wet / dry materials. It has a homogeneous mixing action. The planetary motion of the beater enables faster and better mixing of material at a considerably lesser time. Slow speed is used for dry mixing with less dust generation and faster speed for kneading operation during wet granulation portable mixing bowl with top mounted agitator has a dual advantage of material transfer and no risk of gland packing contamination.

Planetary mixer

Get Price Quote

We offer Planetary Mixer.Planetary Mixer is ideally suitable for through mixing of ointments, creams, lotions, tooth paste etc. In sterile or non-sterile conditions

Flour Kneading Machine

Get Price Quote

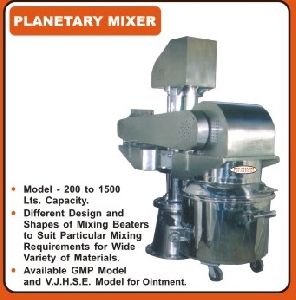

Planetary Mixer Standard

Get Price Quote

Intimate blending of different materials of different consistencies, viscosities, densities, shapes, proportion liquid / liquid, liquid/ solid, solid/solid is achieved effectively by use of planetary mixers, Compact design of machine takes up minimum floor space. Beater arms are available in a range of designs to achieve optimum output for different types of materials Salient Features Product bowl mounted on castor wheels for easy portability, washing and transporting mixed materials Choice of different designs of beaters to suit particular mixing requirements for a wide variety of materials. Flameproof construction optional Higher capacity 750 L and 1000L models with auxiliary beaters. Motorized and hydraulic drive assembly for lifting and lowering Needs comparatively smaller area for installation Electrical control panel with back up fuses and indicator lamps for easy process control Contact parts of SS 316 quality material. SS 304 construction optional Proper selection of Planetary and beater RPMs for different products

Planetary mixer

58,000 Per Piece

1 Piece (MOQ)

Tabletop Planetary Mixer

Get Price Quote

Dough Kneader

Get Price Quote

We are trusted for quality and thus we follow stringent quality procedures to ensure that only defect-free range is delivered to the customers. We settle the financial transactions with our customers through the secured payment procedures. We also settle down upon a variety of negotiable instruments.

Dough Divider

Get Price Quote

- The machine can be sued for all types of dough and is fitted with two standard dividing pistons - The dough hopper can be fitted manually or with lifting / tilting device depending on the production required - The machine can be used either for manual removal of dough pieces or in the semi-automatic bread plant - The divider works on rotating drum principal. The measuring pistons move in rotating drums. - Dough pieces are ejected by gravitational force - The amount of dough conveyed can be adjusted to the required weight to the required weight by means of handwheel - The dough reaches the dividing chamber from the hopper. After the chamber has been closed by the knife, the dough is conveyed into the measuring chamber by the main piston - The volume of this measuring chamber corresponds to the set dough weight - After the rotating drum has turned 90 degrees, the dough piece is pushed out by measuring piston. As the rotating drum moves back, the dough piece is scraped off and drops onto the discharge conveyor. - Two pocket dividing unit producing two pieces of dough - Hand wheel for adjustment of weight volume - Hand wheel for the production speed adjustment (minimum / maximum) cuttings/ minute - Stainless steel hopper with 80 kgs. dough capacity

Planetary mixer

Get Price Quote

Planetary mixer

300,000 - 1,000,000 Per Piece

The planetary mixer is an industrial equipment conceived/made to prepare food, chemical, ceramic dough or other type of product, replacing manual labor through a mechanical system that allows to produce, continuously, large quantities of dough. Discription : Bowl for ingredients placement Mixing element (whisk, hook, flat beater, scrapper or other system) Motors that start the bowl and whisk movements Interconnection of technological process that allows to the operator the control of the mixing process and other labour process (programming times and speeds; mixing elements) The name “planetary mixer” comes from the system used in the equipment that mixes the dough in the planets rotation direction. The planetary mixers Ferneto are ideal to produce pastry products such as emulsions, creams, batters and other sophisticated desserts witch require larger, faster and powerful rotation movements. The range of the planetary mixers Ferneto include an extended equipment set of, suitable for small and large productive bakery and pastry units as well as other food units (catering, hospitality and similar industries). This equipments are available in standard, stainless steel and marine version. The main differences are based on: construction structure, raw material and esthetics features. Do you want home made products with the added value of a machine? Are you looking for an equipment that can assist you? Do you want productive performances keeping higher quality standards? Find out the planetary mixer and know how to improve the quality of your production.

Planetary Blender

Get Price Quote

We are offering Planetary Blender. our comprehensive range of planetary blender is widely acclaimed for its superior performance and longer working life among the clients. owing to the above features, these planetary blenders finds application in various industries. moreover, we can also offer these blenders in customized specifications as demanded by the clients.

Planetary Mixers

Get Price Quote

We are offering planetary mixers. • planetary mixer has facilitated a wide range of operations from the production of vast quantities of products and handling simple mixtures to complex reactions, which involve high internal pressure and controlled temperatures. • we offer these in stirrer designs and generate orbital rotation, just like a beater covers every point of the bowl, to provide efficient mixing results. • planetary mixer has use for manufacturing of medicament, ointments, cosmetics: cold creams, hair dye cream, conditioners, lotions, gels, shampoo, and toothpaste etc. • planetary mixer has advanced drive heads that heads can be raised and lowered by using a manual, hydraulic or electro mechanical means. • the bowls are easily removable and facilitated the users in applications requiring remote discharge and cleaning. • the bowls are design for full vacuum or pressure. • the bowls are also providing jacketed bowls as an optional attachment depending on the heating and cooling requirements of the clients.

Planetary mixer

120,000 Per Piece

Planetary mixer

Get Price Quote

This equipment is basically a mixing assembly where the agitation pattern is of the planetary nature The beater or the agitation assembly rotate around itself as well as travel in a circle in the bowl thereby achieving intimate mixing. Because of special design feature of shifting the mass is uniformly and intimately mixed.

Dough Sheeter

190,000 - 350,000 Per piece

1 piece (MOQ)

Automatic Flour Mixer Machine

20,000 Per Piece

Planetary mixer

Get Price Quote

Planetary Mixer Planetary mixers are an ideal mixer for the products of different viscosities, densities, shapes & proportions. The major uses include the production of latexes, dispersion & micro — dispersion of Chemicals, Explosive & agricultural pesticide formulations. It is suitable for mixing / blending powders as well as through mixing of ointments, creams, lotions, toothpastes, resins, Slurries, ceramics, colors, pigments, rubber & other compounds. Planetary mixers consist of a single r double blade with a high speed dispersion blade (Emulsifier / Homogenizer) Intimate & homogeneous mixing of products is achieved by planetary motion of beaters & centrally located high speed dispersion blade for vacuum jacketed mixer units. They are used in many process operations Ike Homogenization, Dispersion, Emulsification, Grinding , Dissolving, Chemical reaction, Cell disruption & Coagulation Capacity - 3 to 2500 liters

atta maker machine

13,000 Per Unit

Features : High durability Heat resistance Robustness Longer service life Excellent performance Sturdy construction