Vertical Boring Machine

Get Price Quote

Suitable for Automotive Engine Rebuilding - Boring head travels on Ground Guide Ways protected with bellows - Boring Head fitted with hardened alloy gears to give smooth feel and slide on columns - Mechanical Machine with 2 Speed Motor and Six Speed Gear Box - Optional: Machine with AC Drive instead of Mechanical Machine

Deep Drilling Machine

Get Price Quote

Multiple-spindle drilling machines are used for mass production. These machines are great time savers where many pieces of jobs having many holes are to be drilled. Multi-spindle head machines are used in mechanical industry in order to increase the productivity of machining systems. The multiple- spindle drilling machine is a production type of machine. It is used to drill several holes in a work piece simultaneously, in a single setting. This machine has many spindles driven by a single motor and all the spindles are fed in to the work piece simultaneously. These machines may be either horizontal or vertical type. The drill heads consists of several spindles mounted on angular contact ball bearings and driven by a set of gears. For spindles wherein the center distance are very close needle roller thrust bearings are used. The drive to the spindle is by AC spindle CNC motor or by AC induction motor. The speed of the spindles driven by induction motor is varied by using variable frequency drive. The drill head is interchangeable. These multi spindle drilling machines are mainly used in automobile industries for drilling holes in crankcase, cylinder head, connecting rod etc. The drill head is supplied with high pressure through coolant or external coolant depending on the application. The drilling feed is provided by a CNC table or a hydraulic table. The drills are guided in a mobile jig plate or a fixed jig plate depending on the application. The drills are mounted on to the spindle using an adjustable adaptor or a stub tool holder.

Best Deals from Drilling Equipment

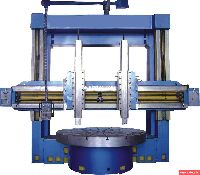

Vertical Boring Machine

Get Price Quote

Table Dia. from 1000-5000 mm, Turning hgt. upto 2000 mm, Fixed Moving cross rail, With Without live tool, Turret Ram, Single Double column construction, Grinding attachment (option).

Heavy Drilling Machine

40,000 Per Piece

1 Piece (MOQ)

Stainless Steel Drilling Tool

Get Price Quote

Radial Drilling Machine

Get Price Quote

Column, Arm, Work Head & Gears are made out of Closed Grain. Parts Properly Balanced. Prior Assembling of Main Gear & Pully. Parts finished on imported Grinding M/c. All Moving Parts Finished to Close Tolerance. Spindle Ram is made out of Alloy Steel. Main Spindle & Pinon are Made out of EN Forged Steel.

HSS Core Drills

Get Price Quote

At the initial stages of using raw material for the production, our dedicated quality staff makes certain that the inputs used are of premium quality. Thus, our offered range is highly appreciated for the quality. Keeping pace with the contemporary market trends, we ensure on-time and safe delivery of the orders.

Seed Cum Fertilizer Drill Machine

Get Price Quote

We offer seed cum fertilizer drill machine. Seed cum fertilizer drill machine is used to plant variety of crops like wheat, maize, millets, pulses etc. It is available in single top box and double top box (one of seed, other for fertilizer) having 891113 tynes & operates with minimum 25 hp tractor gill single top box 9 length (over all) 84" width from divider frame to linked 35" height (from ground level to seed drum top) 15" no of tyne (for rows) 9 no (forged pieces of 25 mm thick flat) wheel position adjustable 8" to 9" gear mechanism 18 teeth gear fitted on 1" dia shaft and 10 teeth gear fitted on m.s wheel no. Of dividersfeeder 9 no. Attached with seed drum wheel position adjustable m s 6 mm thick plate + flat adjustable covering 18 dia" feed mechanism (c I bodies) specially designed seed divider'sfeeders fitted at bottom base of seed drum and will be adjustable according seed body (frame): m s angle 50 x 50 x 6 mm m s flat 65 x 10 mm m s flat 50 x 10 mm body (sheet): m s 2.90 mm 10 gauge m s 2.00 mm 14 gauge prime mover driven with minimum 35 hp tractor and above output approx 1.5 to 2.5 acerhr weight 310 kg gill double top box 9 length (overall) 84" width from divider frame to linked 35" height (from ground level to seed drum top) 45" no of tyne (for rows) 9 no (forged pieces of 25 mm thick flat) wheel position adjustable 8" to 9" gear mechanism 18 teeth gear fitted on 1" dia shaft and 10 teeth gear fitted on m s wheel no of dividersfeeder 9 no attached with seed drum 9 no attached with fertilizer drum wheel position m s 6 mm thick plate + flat covering 18 dia" feed mechanism specially designed seed divider'sfeeders fitted at bottom base of seed drum and will be adjustable according seed body (frame): m s angle 50 x 50 x 6 mm m s flat 65 x 10 mm ms flat 50 x 10 mm body (sheet): m s 2.90 mm 10 gauge m s 2.00 mm 14 gauge prime mover driven with minimum 35 hp tractor & above output approx 2 to 2.5 acerhr weight 390 kg

horizontal line boring machine

Get Price Quote

Boring Bars with appropriate bearings, cones, extra supports and cutters 22 x 1300 mm and 60 x 2500 & 3000 mm Into-Bore Gauge (for measuring without removing boring bar) 35-105 mm and 100-210 mm Tool Grinder Extra Cutter Heads for 30 mm & 48 mm Boring Bars Extension for Boring Bar 260 mm Small Busing for extra support (specify diameter of boring bar) Boring Bar Sag Checking Attachment Bpring Bar Hand Feed Remote Control

Magnetic Core Drilling Machine

82,500 Per Piece

rotary drilling equipment

15,000 Per Piece

1 Piece (MOQ)

Drilling tool

Get Price Quote

Drilling Tools Accessories

Get Price Quote

We are recognized as one of the prime Drilling Tools Accessories Manufacturers and Exporters from India. Various national as well as international clients are placing bulk orders for the Rotary Drilling Tools due to the unmatched quality and inexplicable performance in respective applications. Additionally, customers are eased with the availability of the Relative Drilling Tool Accessories in varied sizes and dimensions that comply with the universally accepted quality norms. Some of the Drilling Tools Accessories included ion our array are as mentioned below : Soil Teeth and Holders(T25 & T18) with Pin and Lock Replaceable T.C Bits Welding Bars T.C Bits Grab Teeth Bullet and Holder 19mm Bullet and Holder 25mm Bullet and Holder 30mm

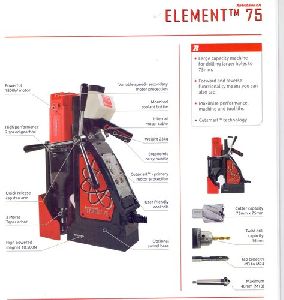

Magnetic Core Drilling Machine

Get Price Quote

2 Unit (MOQ)

cylinder boring machines

Get Price Quote

Pillar Type Drilling Machine

Get Price Quote

We are offering pillar type drilling machine. Backed by experienced and expert team we are offering range of pillar type drilling machine.

Rotary Core Barrels

Get Price Quote

Gamzen a trusted firm based in India, concrete mixer manufacturer, supplier, exporter and service provider of core barrel to India and overseas including Asia, Gulf, Europe and America. Quality and safety assured products including rotary have exported different nations as well as international customers with clients' 100% satisfactions. Rotary drilling barrels are available in 500 mm to 2500 mm. Clients can also make orders as per requirement T.C. bits. We designed and manufactured same as ISO standards and international regulations and supplied as per local climate and client's requirement. Core barrels are available with efficient and security. Range of equipments manufactured by ISI and international certified tools and devices to meet our stringent safety and quality control Standards. Available according to requirement of sectors including size and features in addition to a full range. Consultation and supplier of construction machinery, equipment and all solutions to the commercial industry by our experienced and professional team. Core Barrel Features Useful as per domestic environment Low maintenance and Cost-effective Reliable and long lasting Manual and hydraulic shifting allow

Fully Automatic Horizontal Line Boring Machine

Get Price Quote

EXTRA EQUIPMENT : Boring Bars with appropriate bearings, cones, extra supports and cutters 22 x 1300 mm and 60 x 2500 & 3000 mm Into-Bore Gauge (for measuring without removing boring bar) 35-105 mm and 100-210 mm Tool Grinder Extra Cutter Heads for 30 mm & 48 mm Boring Bars Extension for Boring Bar 260 mm Small Busing for extra support (specify diameter of boring bar) Boring Bar Sag Checking Attachment Bpring Bar Hand Feed Remote Control

Radial Drilling Machine

Get Price Quote

This is a precision heavy duty all geared radial drilling machine. The machine is supplied complete with suitable HP 440 volt 3 phase AC electric motors for main spindle, Elevating motor and for Coolant pump with Control panel with limit switches. Heavy Duty Box table is also supplied as standard accessory. It is available in three models with drilling capacities of 38mm and 50mm in mild steel and with distance between Spindle centre to Column centre of 1160mm, 1270mm and 1500mm.

Radial Drilling Machine

Get Price Quote

Description: Heavy Duty Radial Drilling Machine Large base plate with broad column to withstand heavy load Column sleeve carrying arm rotates on ball bearing at top & bearing rollers at bottom Spindle is made of alloy steel. It moves on taper roller bearing Auto Feed 0.115 mm/rev is standard. Six Feed Range of 0.12- 1.2 mm/rev is optional Optional: Spindle Speed of 50-1600 RPM with Dual Speed Motor Accuracy: As per IS Standard 2199 Movement of drilling head parallel to base plate 0.015mm/ 1000mm of traverse True running of taper in spindle at top position 0.015mm Application: Machining of large components in Workshops and Fabrication Shops Drilling, Tapping, Counter Boring, Reaming, Screwing, Thread Cutting and Counter Sinking Suitable for Steel, Cast Iron, Alloy Steel, Stainless Steel, Medium Carbon Steel, Non-Ferrous Material Accessories:Box Table, Drill Vice, Machine Vice, Coolant System, Tapping Attachment

Paper Drilling Machine

Get Price Quote

Max. Drilling Thickness : 40mm,Max. Central Distance : 180mm,Diameter of Holes : 2 - 8mm,Speed : 2800Rmin,Main Motor : 220V 50Hz, 0.25 Kw Weight : 30 Kgs,

Core Drill Bit

Get Price Quote

micro

Get Price Quote

Simple in its design, it's very powerful and stable in use!

Horizontal Floor Borer

Get Price Quote

Radial Drilling Machine

Get Price Quote

Drill Grinding Attachment

Get Price Quote

rock drill machine

Get Price Quote

Deep Hole Drilling Machines

Get Price Quote

Column-type Planer-type Gantry-type Machines Vertical Horizontal Spindle Machines Single Multi-Spindle High Precision Rigid Construction for Resulting in Good Surface Finish

Edm Drilling Machine

Get Price Quote

Electro-Discharge-Machining as a manufacturing process has travelled from spark erosion, to precision machining processes like Wire-cut EDM & EDM Drilling. With our rich experience of working with industries that have adopted this process as an integral part of their manufacturing, we are in a position to offer a variety of solutions that make EDM processes more efficient. We have been the leading EDM Wire Manufacturers and Suppliers in India since 1985. In addition to our 2 state-of-the-art EDM Wire manufacturing factories, we also offer our customers the full range of EDM Consumables like EDM Wires, EDM oil, EDM Graphite, Resin, Filters, Metallic Electrodes, EDM Machine Spares, etc. It's always been our philosophy to not just be suppliers, but also to be process partners to our customers. As your partner it is essential that we provide you with quality products and impeccable service

Core Drill Machine

13,500 Per Piece