Drum Dryer

Get Price Quote

Drum Dryer that we provide is used for converting the molten slurriers into dried solid flakes. In this Drum Dryer the material is fed into a feed hopper, which directs the materials towards the face of the rotating drum. Drum Dryer is heated or cooled depending on the application in order to enable the material to cling to the outside of the drum. The material gets dry during the rotation process of the Drum Dryer and is further removed by a blade or scrapper that is mounted along the length of the roll. Our Drum Dryer is used for processing various materials like sulphur dyes, waxes, caustic soda, fatty acids, resins, guar gum, etc.

drum dryers

Get Price Quote

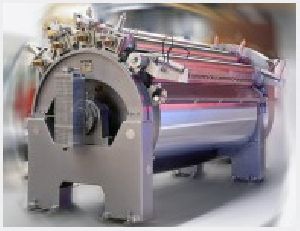

SYSTEM : The Sakav steam heated Drum Dryer is noted for its high thermal efficiency in the removal of water and/or solvents from a wide range of solutions, slurries and suspensions. The ratio of steam consumption to evaporation can be as low as 1.2:1 and seldom more than 1.5:1 CONSTRUCTION MAIN FRAMES : Heavy duty cast iron or fabricated carbon steel construction. DRYING DRUMS : High engineering hard chrome plate or hard cast iron, stainless steel or custom alloys. KNIFE BARS : Cast iron or stainless steel clad cast iron with pneumatic operation as standard. (Oscillating knife mechanisms optional). KNIVES : Sheffield steel, special stainless steel, Teflon, or stainless steel blade holders tipped with beryllium bronze for custom applications. DAM PLATES : Provided where necessary, faced with Teflon or similar. DRUM DRIVES : Fixed or variable speed. Safety gear : (Twin Drum) Spring loaded. ENCLOSURES : Vapor extraction hood, total, dust tight or nitrogen atmosphere capable. VACUUM CASING : Plain or steam jacketed. STANDARD AUXILIARIES : Side and cross conveyors, traversing feed gear, automatic feed control, product brakers. Applications : Milk products, baby foods, breakfast cereals, fruit and vegetable pulps, starches, spent yeast, chemicals, biologicals.

Best Deals from Drum Dryer

Drum Dryer

Get Price Quote

Drum Dryer is a kind of highly efficient, stable and reliable heating drying equipment (dryer), it is designed by Star Trace to dry materials of high moisture or strong stickiness. Rotary dryer has a better performance than tube bundle rotary dryer, blade rotary dryer. Rotary dryer has the features of big capacity, low energy cost and high efficiency. Application Simplified and easy to operate but very effective control system Drum Dryer is widely used for drying slag limestone, coal powder, slag, clay, etc. Dryer can also be used in building materials, metallurgy, chemical and cement industry. Dryer mainly consists of dryer body, raw material feeding plate, driving and supporting device, seal ring, etc. Dryer can be generally divided into four types, they are: rotary dryer, triple-drum dryer, indirect heat transfer dryer, vertical dryer. Different kind of dryer has its own characters and advantages; the specific choice of a special dryer depends on different elements. The customer can consult Star Trace to select the most suitable dryer. Application 1.It takes les time to dry. 2.Thermo sensitives drugs can also be dried. 3.Drum dryers occupies less space. 4.In order to reduce the temperature of drying the drum can be enclosed in a vacuum chamber. 5.Rapid drying takes place due to rapid heat and mass transfer.

Industrial Drum Dryer

Get Price Quote

drum dryers

Get Price Quote

Drying solutions to produce cereal based baby foods (weaning foods), drink cereals, brewers yeast, fruits & vegetables, milk powder (for chocolates, gulab jamun & other Indian sweetmeats), also lines for making potato flakes / potato granules, maleic anhydride, phthalic anhydride, etc

Drum Dryer

Get Price Quote

Operating Principle This Drum Dryer is basically a conduction dryer. Wet feed film (in liquid or paste form) is applied to the rotating metal cylinder inside which, a heating medium is supplied. Material film dries to the final moisture level and is scraped off. Voice Engineers Drum Dryer Manufacturers are suitable for continuous drying of bulk goods of industry and agriculture, like e.g. for drying of green waste. The dryer can be designed as a stationary machine or as mobile plant, mounted on a frame. Operating method The wet product is fed into the Drum Dryer via suitable feed devices. Transporting blades on the feed side of the drum take up the product and carry it to the drum fixtures. The choice of drum fixtures is determined by the product characteristics. The product is usually dried in direct flow. The wet product meets the hot drying gas with a temperature up to 1000 °C. The retention time of the product in the dryer depends on the drum speed, drum inclination, kind of drum fixtures, flow rate of the drying gas and the damming device at the end of theDrum Dryer Manufacturers Voice Ingineers is Supplier, designer and Drum Dryer Manufacturers Special Features of Drum Dryer Suitable for handling liquid or pasty feeds. Product in powdery, flaky form Uniform drying due to uniform application of film. Medium range capacities. Very High thermal efficiency Minimum Thermal degradation Continuous operation Accomplishment of drying in single step, eliminating need for any intermediate concentration processes. APPLICATION : Paraffin wax, Clay, fire clay, plaster slag, incinerating and composing refuse, waste products, residue and sewage sludge, agricultural products , greenstuffs, grain, root vegetables, etc

Double Drum Dryer

Get Price Quote

Drum Dryer

Get Price Quote

The feed stock is introduced into a singleor twin steam heated drum dryer in a uniform film by use of variety of feeding devices and arrangements depending upon the material to be dried. The moisture is dried off in less than one revolution and the dried solid is removed usually in the form of a thin sheet/powder by doctor blade.Advantages:• Minimum Thermal degradation• High thermal efficiency• Fine and spheroidal product• Minimum labor requirements• High output• Continuous process• Accomplishment of drying in single step,eliminating need for any intermediate concentration processes.

Drum Dryer

Get Price Quote

Drum Dryer, Vacuum Pump

flakers & drum dryers

Get Price Quote

flakers & drum dryers, Chemical Reactors, Limpet Reactor, Nutsche Filter

Drum Dryer

Get Price Quote

Drum Dryer, oil dryer, Spin Flash Dryer, Rotary Vacuum Dryer

Flakers Rotary Drum Dryer

Get Price Quote

Flakers Rotary Drum Dryer, Laboratory Equipment, Reactor Vessel

Double Drum Dryer

Get Price Quote

Double Drum Dryer

Double Drum Dryer

Get Price Quote

Double Drum Dryer

drum drier

Get Price Quote

drum drier

Drum Dryer

Get Price Quote

Drum Dryer, S S vessels, Mixing Vessel, Heat Exchanger, Reactor Vessel

Vacuum Drum Dryer

Get Price Quote

Vacuum Drum Dryer, wiped film evaporator, Process Consultancy Service

Double Drum Dryer

Get Price Quote

Double Drum Dryer, Membrane Dryers, Regenerative Air Dryer

Double Drum Dryer

Get Price Quote

Double Drum Dryer, Drum Flaker

Rotary Drum Dryer Machine

Get Price Quote

Rotary Drum Dryer Machine