Rotary Cascade Dryer

800,000 Per piece

1 piece (MOQ)

The complete drying plant compromises Rotary Cascade Dryer, Air Heater, Dryer Inlet Hood, Exhaust Hood, Exhaust Air Fan & Ducting and all necessary Controls. Duty : To Dry about 750 Kg/hr. of Chilly Flakes from approximately 20% initial moisture to 8-10 % final moisture. Dryer Drum : 3 Ft Diameter X 28 Ft. long dryer drum fabricated in Stainless Steel plate SS-304 , with internal flights and lifters fabricated and bolted to Stainless steel angle sections welded to the shell plates to ensure adequate contact between the drying air and the material being processed. The drum is fitted with two cast or forged steel tyres, mounted on carbon steel spacer blocks fitted to a reinforcing band. The tyres run on four cast or forged steel support rollers shrunk fit on steel shafts with shaft mounted spherical roller bearing plummer blocks. A segmental cast steel chain ring is fitted around the periphery of the dryer drum. Support Frames: The complete dryer drum assembly is supported on two fabricated carbon steel roller support frames, the feed end support frame carrying the locating roller assemblies. Both roller support frames are fitter with safety guards. Drum Drive: The dryer drum is driven by a T.E.F.C. electric motor through V-belt drive, gearbox, pinion and chain to the drum drive chain wheel. Motor, gearbox and V-belt, etc. are mounted on a fabricated carbon steel baseplate. All drives are completely enclosed in suitable safety guards. Air Heater : The drying air is provided by means of Electrical Operated, firing into a refractory lined carbon steel combustion chamber connected to the dryer inlet end hood. It can also be operated with Electrical Heater of 30 KiloWatts rating. Inlet End Hood :The inlet end of the drum is totally enclosed with a Stainless steel fabricated enclosure, complete with labyrinth seal. and stainless steel material inlet chute. The inlet hood is supported by a suitable rolled steel section support structure. Outer End Hood : The outer end of the drum is totally enclosed with a carbon steel fabricated hood complete with inspection access door, exhaust air outlet chute. A labyrinth type flexible seal is fitted to the rear hood plates around the drum opening. The outlet end is supported by a suitable rolled steel section support structure. Exhaust Air Fan : The exhaust air is drawn from the dryer by a centrifugal fan, complete with electric motor, V-belt drive and drive guard. Exhaust Air Ducting : The exhaust air from the dryer is conveyed via a Stainless steel duct from the outlet end hood to the cyclone and from the cyclone to the exhaust fan. A manually operated butterfly type valve damper is fitted in the exhaust duct between the cyclone and exhaust fan. Control System : Inlet air temperature is measured by means of a thermocouple located in the inlet end hood connected to a temperature indicator/recorder. Exhaust air temperature is measured by a thermocouple located in the exhaust air duct connected to a temperature indicator/recorder. The Electrical output is controlled by means of a suitable Thermostat via a suitable transmitter from either of the two temperature indicator controllers. All necessary motor control gear, relays, overloads, etc. and temperature indicators/recorders are housed in a carbon steel control cabinet which will be prewired for correct sequential star-up and operation of the plant.

Vacuum Tray Dryer

Get Price Quote

We are vacuum tray dryer manufacturer in India . The most popularly known and used batch dryer is a vacuum dryer and we are a well-known Vacuum Tray Dryer Exporter. They are shaped in a box structure. The medium flowing through the heating plates is water, steam or thermal oil. The gap between the heating plates is invented primarily by the surface loading and the foaming of the product. To void retrograde condensation the cabinet walls are indirectly preheated by the heating plates. We, Vacuum Tray Dryer Exporter offer you this Vacuum Tray Dryers at very reasonable rates Vacuum Tray Dryer works under vacuum conditions on the conduction principle, known as vacuum tray dryer working principle. Store the products inside the dryer, which consists of multiple shelves and trays. The topmost frame is a dummy shelf placed there to ensure proper heating and prevent the dried powder from escaping into the solvent extraction system. Brackets are constructed hollow with baffles cum stiffeners placed in between shelves. Every shelf has an inlet and outlet nozzle connected to an inlet and outlet header through these nozzles. ADVANTAGES Very efficient heat sensitive Materials can be dryers in containers or enclosures.The average drying temperature is much lower than standard dryers Heat transfer throughout the body helps in the quick-drying of larger surface areas. Dries considerable moisture as compared to traditional dryers Quality of dries material is beer than that of the regular dryers SALIENT FEATURES Stainless steel construction (SS 316L/316/304) Easily removable hollow pad type heating shelves Dedicated fluid heating and circulating systems The thermal efficiency of 60% to 80% Provision for Explosion Vent / Rupture Disc on body & Validation Port on Body On Chamber Vacuum break valve is provided High-quality interlocking for doors to the chamber Uniform heating flow Branded immersion heaters Heavy-duty MS/SS door fied on hinges Single and double doors (for large models) Complete automation w/ PLC controls (Op

Best Deals from Dryer Machine

Rotary Dryer

Get Price Quote

Fluid Bed Dryer

100,000 - 500,000 Per Piece

Fluid Bed Dryer

Get Price Quote

Delcra Centrifugal drying machine

55,000 - 80,000 Per Nos

5 Piece (MOQ)

copper filter dryer

18 - 24 Per Piece

400 Piece (MOQ)

Fluid Bed Dryer

Get Price Quote

1 nos (MOQ)

pharmaceutical tray dryer

100,000 - 1,500,000 Per Bag(s)

100000 Bag(s) (MOQ)

pharmaceutical tray dryer, Fluid Bed Dryer, Ointment Manufacturing Plant

Gold Dryer Machine

Get Price Quote

1 piece (MOQ)

rotary vacuum dryers

Get Price Quote

As a celebrated Manufacturer and Supplier of Rotary Vacuum Dryers, we attempt to gain 100% customer satisfaction. Our wide range is manufactured using matchless raw material. We meet the highest parameters and norms of quality set by the industry. Designs are made by keeping several specifications in mind. The quality on offer, which is loaded with features such as high functionality and minimal maintenance, is available for economical prices.

Fluid Bed Dryers

550,000 - 1,500,000 Per Piece

1 Piece (MOQ)

The fluid bed dryer DNFBD-Lab is used in quality control, sample preparation and R&D departments. It permits the gentle drying of organic, inorganic, chemical or pharmaceutical bulk materials without localized overheating. Suitable materials can be coarse, fine, crystalline, fibrous or leafy. The powerful fan of the fluid bed dryer ensures optimal air throughput so that the products to be dried are loosened up and thoroughly mixed resulting in short drying times. With the interval operation the fluidized bed is mixed even better. Temperature, drying time and air volume can be set though PLC & HMI and adjusted continuously.

Steam Tray Dryer

110,000 Per Piece

1 Piece (MOQ)

Fluid Bed Dryers

Get Price Quote

We are the main supplier of this product.

Fluid Bed Dryer

Get Price Quote

We are offering fluid bed dryer. Bullet very versatile process equipment. Bullet fully automatic operation based on plc control. Bullet minimum handling and more hygienic. Bullet top mounted telescopic cylinder for auto bag shaking. Bullet clamp type bottom mesh for container. Bullet capacity available from 2.5 kgs. To 500 kgs. Bullet moc ss 304 316 316l. Bullet cgmp with documentation.

Auto Scrubber Drier

Get Price Quote

Semi Dryer

Get Price Quote

We are offering semi dryer. • the three baskets semi drying systems are being use inline with soft gelatin capsules encapsulation machines to maintain the proper shape of capsules after encapsulation to avoid the joint formations of capsules, colour migration and de-shape etc. • auto-transfer of capsules between baskets • plc ensures optimum drying time in each basket depending on number of basket. • high cfm blowers are using ambient air to remove oil and moisture from the surfaces of the capsules. • all contact parts with product are made of s.s 316.

Fluid Bed Dryer

Get Price Quote

We are backed with highly experience packaging experts and team members; they ensure that the packaging is done with utmost proficiency and keeping in mind the globally accepted norms. We are capable of delivering the orders on time and at any desired Palghar(India) as we are supported by up-to-the-minute facilities.Details : Very versatile process equipment. Fully automatic operation based on PLC control. Minimum handling and more hygienic. Top Mounted telescopic cylinder for auto bag shaking. Clamp type bottom mesh for container. Capacity available from 2.5 kgs. To 500 kgs. MOC SS 304 / 316 / 316L. cGMP with documentation.

conveyor dryers

100,000 - 500,000 Per

Sentry fegul drayer

33,000 Per Set

Buyers across Mumbai(India) and other markets can contact us for purchasing our product all year round. Utilizing the best-grade wrapping supplies, we pack our products securely to endure shipping and tag it correctly to offer product details such as the address of manufacturer/ distributors, MRP, quantity etc. Our Turbine Blower has a glossy surface with polished edges and is available in different dimensions

Fluid Bed Dryer

125,000 Per Piece

1 Piece(s) (MOQ)

Manufacturer of standard and custom fluid bed process dryers for industrial applications. The Fluid Bed Dryer manufactured by us is ideal for the rapid, even drying of chemical, pharmaceutical and food products. Our Fluid Bed Drying Machine is capable of drying materials in any form be it, granular, powder or crystalline form. Our product precisely maintains moisture content up to 20% which is ideal for pharmaceutical and chemicals. Can be used for different cooling process applications in specialty chemicals, fertilizers, plastics, food, pharmaceuticals and cosmetics manufacturing markets.

Tray Dryer Machine

Get Price Quote

Main Features :- All contact parts of SS 316 / 316L as cGMP standard.Available in wide range models from 6 to 192 raise capacity.Design for uniform circulation of hot air in the drying chamber.Heating cold and fan motor having electrical inter locking for safety of heating elements.Electric/Steam/Thermic Fluid heating system.Fresh air inlet and outlet air flow can be adjusted with damper control valve

Tray Dryer

Get Price Quote

Double Walled Construction- Exterior made of mild steel powder coated (STD Model) & Interior made of stainless steel 304. Heating: Three sides uniform heating through forced air heaters made up of High grade. Air Circulation: Fan arrangement for uniform air circulation. Temp. Range: 5ºC above ambient to 250°C Resolution : ± 2°C Temperature Controller: Digital temperature controller. High grade glass wool insulation Aluminum Trays. A cabinet tray dryer is an enclosed insulated chamber in which trays are placed on top of each other in trolleys. Tray Dryer are used where heating and drying are essential parts of manufacturing process in industries such as Chemicals, Dye stuff, Pharmaceutical, Food Products, Colors etc.

refrigeration air dryers

Get Price Quote

Ingersoll Rand’s refrigerated dryers offer design features that reduce energy consumption and improve reliability. Corrosion-resistant heat exchangers reduce airflow restrictions, providing more efficient throughput with less wasted energy. A built-in stainless steel demister efficiently removes all moisture. Reliable, fully hermetic compressors use environment friendly R134A refrigerant.

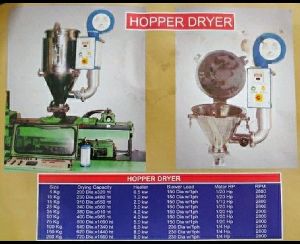

Hopper Dryer

40,000 Per Set

1 Piece (MOQ)

Price of the machine will be according to the size

Tray Dryer

Get Price Quote

We supply Tray Dryer that is adequately designed by our designers and adroit personnel who take every care in the fabrication of a durable and highly efficient range of machines. Available in various models such as 12 trays, 24 trays, 48 trays, 96trays, these are high in performance and low on maintenance. The significant traits of our exclusive array include the following: Models: 12 trays, 24 trays, 48 trays, and 96 trays Construction- Robust construction Built on formed angles of 3mm thick sheet and suitably reinforced with angles and sections External walls are manufactured from 1.6mm thick stainless steel sheets of 304 qualities The internal of the dryer is built of 1.6 mm thick s.s 304 quality sheets insulated with minimum 50 mm thick glass wool insulation and caddied with s,s, polished sheets Fresh air inlet through 20 micron pp cloth filters and a adjustable air outlet flap and a door at the front Explosion proof door is locked with the help of spring loaded ball latches with suitable pressure. To prevent leakages door lips are having neoprene rubber gasket Finishing- Designed and manufactured as per GMP standard Aesthetic look Buffed externally to 150 grit matt finish Internally buffed to 220 grit mirror finish Electrical heating- The Air inside the Tray Dryer is heated by "U" tube S.S.304 air heaters each of 1 KW. The heaters are fitted on the sides of the dryer to facilitate uniform heating. Maximum temperature attained inside the dryer is 100' C The temperature is indicated and controlled by a Digital Temperature indicator cum controller over full range of heating load The total heating load for it will be 12 Trays Dryer - 4 KW 24 Trays Dryer - 6 KW 48 Trays Dryer - 12 KW 96 Trays Dryer - 24 KW To prevent the heaters from becoming red hot these are inserted inside tubular pipe The terminals of the heaters are brought outside the dryer to make it safer for operations for solvent based products

pharmaceutical bed dryers

Get Price Quote

pharmaceutical bed dryers, industrial pharmaceutical machinery

Rotary Vacuum Dryer

90,000 Per unit

Fluid Bed Dryer

Get Price Quote

Fluid Bed Dryer is capable of drying materials in any forms like granular, powder or crystalline. Afluidized bed of solid particles with a stream of air passing up-ward through the particles at a rate great enough to set them in motion. As the air travels through the particle bed, the particles behave as boiled water. The active motion creates the potential for improved mixing and results an isothermal property. In a bubbling fluidized bed, no temperature gradient exists within the mass of the fluidized particles. Because the temperature and volume of the air can be precisely adjusted, the process achieves fast heat transfer making it very efficient,

Pharmaceutical Hot Dryers

75,000 - 250,000 Per Piece