Tray Dryer

220,000 Per piece

1 piece (MOQ)

Fluid Bed Dryers

550,000 - 1,500,000 Per Piece

1 Piece (MOQ)

The fluid bed dryer DNFBD-Lab is used in quality control, sample preparation and R&D departments. It permits the gentle drying of organic, inorganic, chemical or pharmaceutical bulk materials without localized overheating. Suitable materials can be coarse, fine, crystalline, fibrous or leafy. The powerful fan of the fluid bed dryer ensures optimal air throughput so that the products to be dried are loosened up and thoroughly mixed resulting in short drying times. With the interval operation the fluidized bed is mixed even better. Temperature, drying time and air volume can be set though PLC & HMI and adjusted continuously.

Best Deals from Dryers

rotary vacuum dryers

Get Price Quote

As a celebrated Manufacturer and Supplier of Rotary Vacuum Dryers, we attempt to gain 100% customer satisfaction. Our wide range is manufactured using matchless raw material. We meet the highest parameters and norms of quality set by the industry. Designs are made by keeping several specifications in mind. The quality on offer, which is loaded with features such as high functionality and minimal maintenance, is available for economical prices.

Gold Dryer Machine

Get Price Quote

1 piece (MOQ)

Refrigerated Air Dryers

Get Price Quote

Ingersoll Rand’s refrigerated dryers offer design features that reduce energy consumption and improve reliability.Corrosion-resistant heat exchangers reduce airflow restrictions, providing more efficient throughput with less wasted energy. A built-in stainless steel demister efficiently removes all moisture.Reliable, fully hermetic compressors use environment friendly R134A refrigerant.

Alano Ultima 730 - Auto Scrubber Drier

Get Price Quote

Area Coverage / Hour: ~ 16,000 Sq. Mtr (4 Acres) per hour Fuel consumption: Less than 1.35 Litres of diesel per hour under normal conditions Total operational cost: 80% less than labour cost on a per Sq. Mtr. Basis Sweeping process: Vacuum power assisted multi speed brush; Multi speed machine Speciality: Can sweep dust / debris / leaves / pebbles simultaneously Lowest Economy: Lowest cost of acquisition, operation & maintenance in it’s range Sweeping standard: Excellent cleanliness with efficiency without any dust emission Spares & service: 100% availability any time at client’s door steps Machine useful for: Public streets / internal roads / open area / large warehouses. Floors with concrete, asphalt, bitumen, paver blocks & evenly laid Cobol & normal surfaces Manoeuvrability: Easy on speed breakers, undulations, gradients due to high ground clearance Gradability: 35 degrees Product suitability: Made for Indian conditions Features: Multi Utility power sweeper - Trailer 700 KG gross weight- Fork lift – 450 KG to a height of 1200 MM

Fluid Bed Dryers

Get Price Quote

We are the main supplier of this product.

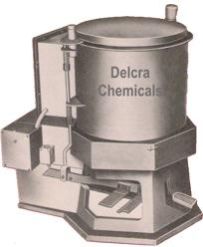

Delcra Centrifugal drying machine

55,000 - 80,000 Per Nos

5 Piece (MOQ)

ROTOCONE VACUUM DRYER

Get Price Quote

Rotocone Vacuum Dryer is suitable for drying materials that cannot resist high temperature, easily oxidized materials, volatile materials that should be retrieved, and potent irritants and poisonous in nature. The Rotocone Vacuum Dryer with improved technology integrates during operation under vacuum. The Rotocone Vacuum Dryer facilitates enhanced drying efficiency, low-temperature operation, and process economy by total solvent recovery. It helps cGMP base working by achieving optimum dust control while offering efficient charging and discharging of materials. The drying unit equipped with lump breakers initially breaks large lumps and subsequently powders them (in a single cone). The dryer’s rotary action, together with the breakers’ mechanical action, cuts down drying time and gives a lump-free product. ADVANTAGES Reduces drying time Eliminates the need for re-drying of lumps Avoid handling and exposure of the final product. Gives uniform size dry product. The system can process crystalline or amorphous powders, which are prone to lumps Easy to clean the internal surface ensures the purity of the product. Optimum and continuous vacuum maintenance during process Uniform material shuffling over the heated contact surface of the Cone. DRIVE Gear Box & Motor Direct Coupled and Gear Box to Cone Drive sha Bull Gear-Pinion Gear Drive. Extended sha (drive side) so that drive unit can be kept in service zone (d required). The vacuum loading system of wet material into the Cone.

Steam Tray Dryer

110,000 Per Piece

1 Piece (MOQ)

Fluid Bed Dryer

100,000 - 500,000 Per Piece

Fluid Bed Dryers

Get Price Quote

ADVANTAGES : In ordinary Tray Dryer, heat passes through longer distance whereas in Fluid Bed Dryers the heat passes through floating material and vapor diffuses through a small distance, due to this the material dries very fast. As the temperature through the Fluid Bed Dryer is uniform there is uniformity in drying of the materials, which in turn helps to achieve higher production as compared to other Dryers. In Fluid Bed Dryer, the material comes in close contact with the drying air at low temperature and for a short period and hence there are less chances of the physical and chemical properties of the products/materials changing during the process of drying as compared to Tray Dryer where the material is not in close contact with the Drying Air. In Fluid Bed dryer, the product / materials are kept in one container and this saves time, labor, cleaning, loading and Unloading, which is not in Tray Dryer. The floor space required in Fluid Bed Dryer is less as compared to Tray Dryer. In Fluid Bed Dryer, three times more production can be given within a specified period than in a Tray Dryer SPECIFICATION PRODUCT CONTAINER TROLLEY : Fabricated out of heavy gauge Stainless Steel and provided with glass window. The base of the container is fitted with a specially designed plate of Sandwich Type construction and shall be air tight. This maintains even distribution of drying air and uniformity in drying. HEATING : The Fluid Bed Dryer can be heated either by electrically or by steam. Steam Units will be provided with Heat Exchanger and Electrical Units will be provided with Open Type Heating Elements. PRODUCT FILTER : This is fabricated of Fabric Cloth and can be easily fitted in the Dryer and can be removed as well whenever required for laundering conveniently. CONTROLS : All the main controls have been fitted together in a separate Control Box in front side of the Dryer. The Starter for Fan Motor and other electrical instruments shall be fitted in the Control Box. Steam heated models shall be provided with solenoid valves for Temperature Control. 'SAKAV' is involved in continuous innovative developments to incorporate the latest technology. As such Specifications are subject to change without notice. ROTARY ATOMISER SAKAV with its in-house design capabilities ha built and supplied a range of Rotary Disc Atomizer. These are belt driven units with standard electrical motors. A number of models are available with wheel diameters of 100mm to 350mm and are suitable for capacities from 5 lit/hr to 10,000 lit/hr Various configurations such as orifice, pin, vane with stainless steel and ceramic wear parts are available. A variety of lubrication systems starting from continuous drip to fully automatic forced lubrication systems can be provided. Speed variations are achieved by changed pulleys or variable frequency drivers. TEST FACILITY Fully equipped dedicated Pilot Spray Dryers are available for conducting trials on customers samples and simulation of ideal drying parameters for individual products. Assessment of their physical properties such as moisture content, approximate particle size distribution and bulk density. Testing is an on-going process and SAKAV has, over the years, built-up a large data base for a wide variety of products. THE CHAMBER OPTIONS The chamber configuration plays an important part in meeting the end product requirements. As is apparent from the table there is an endless number of possible combination. Some of these have been depicted below. FLAT ROOF This is the most widely used configuration of spray chamber with flat roof construction. Co-current swirling air flow pattern is used in conjunction with centrifugal atomization. Generally used for producing a uniform fine powder. Dry powder can be collected partly under the chamber and the fines from the cyclone. Alternatively a single point collection under the cyclone can be provided. Can be adapted for nozzle atomization with an add-on air distributor. TALL FORM - BUSTLE The standard Tall Form Bustle construction with co-current linearized air flow pattern is sued with pressure nozzle atomization systems. The dry product is usually coarser than centrifugal disc atomized product. The bustle construction enables separation of coarse fraction below the chamber and the fines can be collected from the cyclone. This configuration is deal where fines recycle is used for product agglomeration. TWO STAGE A configuration consisting of Tall Form Spray Chamber with a second stage Fluid Bed Dryer is used for special applications. This configuration is used for products requiring longer drying times which cannot be provided in Spray Chamber. This occurs when a coarse product has to be dried to a very low moisture content or when the product to be dried is hygroscopic in nature.

Tray Dryer

Get Price Quote

Double Walled Construction- Exterior made of mild steel powder coated (STD Model) & Interior made of stainless steel 304. Heating: Three sides uniform heating through forced air heaters made up of High grade. Air Circulation: Fan arrangement for uniform air circulation. Temp. Range: 5ºC above ambient to 250°C Resolution : ± 2°C Temperature Controller: Digital temperature controller. High grade glass wool insulation Aluminum Trays. A cabinet tray dryer is an enclosed insulated chamber in which trays are placed on top of each other in trolleys. Tray Dryer are used where heating and drying are essential parts of manufacturing process in industries such as Chemicals, Dye stuff, Pharmaceutical, Food Products, Colors etc.

copper filter drier

16 Per Piece

400 Piece (MOQ)

Sentry fegul drayer

33,000 Per Set

Buyers across Mumbai(India) and other markets can contact us for purchasing our product all year round. Utilizing the best-grade wrapping supplies, we pack our products securely to endure shipping and tag it correctly to offer product details such as the address of manufacturer/ distributors, MRP, quantity etc. Our Turbine Blower has a glossy surface with polished edges and is available in different dimensions

conveyor dryers

100,000 - 500,000 Per

Semi Dryer

Get Price Quote

We are offering semi dryer. • the three baskets semi drying systems are being use inline with soft gelatin capsules encapsulation machines to maintain the proper shape of capsules after encapsulation to avoid the joint formations of capsules, colour migration and de-shape etc. • auto-transfer of capsules between baskets • plc ensures optimum drying time in each basket depending on number of basket. • high cfm blowers are using ambient air to remove oil and moisture from the surfaces of the capsules. • all contact parts with product are made of s.s 316.

Fluid Bed Dryer

125,000 Per Piece

1 Piece(s) (MOQ)

Manufacturer of standard and custom fluid bed process dryers for industrial applications. The Fluid Bed Dryer manufactured by us is ideal for the rapid, even drying of chemical, pharmaceutical and food products. Our Fluid Bed Drying Machine is capable of drying materials in any form be it, granular, powder or crystalline form. Our product precisely maintains moisture content up to 20% which is ideal for pharmaceutical and chemicals. Can be used for different cooling process applications in specialty chemicals, fertilizers, plastics, food, pharmaceuticals and cosmetics manufacturing markets.

Fluid Bed Dryer

Get Price Quote

We are backed with highly experience packaging experts and team members; they ensure that the packaging is done with utmost proficiency and keeping in mind the globally accepted norms. We are capable of delivering the orders on time and at any desired Palghar(India) as we are supported by up-to-the-minute facilities.Details : Very versatile process equipment. Fully automatic operation based on PLC control. Minimum handling and more hygienic. Top Mounted telescopic cylinder for auto bag shaking. Clamp type bottom mesh for container. Capacity available from 2.5 kgs. To 500 kgs. MOC SS 304 / 316 / 316L. cGMP with documentation.

Fluid Bed Dryer

Get Price Quote