Laboratory Padding Mangle

Get Price Quote

1 Piece (MOQ)

Jewellery Dyeing Beaker

70,000 Per Piece

Best Deals from Dyeing Machine

Bath Beaker Dyeing Machine

Get Price Quote

Since the inception of our organization, we are successfully engrossed in supplying a quality gamut of Bath Beaker Dyeing Machine. Manufactured using factory tested components and ultra-modern technology, this dyeing machine is fabricated in tandem with market quality standards. This dyeing machine is widely demanded for dyeing fabric. In addition, our patrons can purchase this dyeing machine at reasonable rates from us.

Laboratory Jigger Machine

Get Price Quote

Laboratory jigger machine suitable for dyeing of cotton, Linen, Viscose, Rayon, Blended fabrics with dyestuff such as Direct, Acid, Basic, Aoics, Reactive up to a temperature of 95 degree centigrade. Fully automatic operation of temperature, direction reversal speed of fabrics. Differential gear box for uniform speed. Adjustments for fabric tension.Tale top model. This is a Laboratory Jigger Machine for processing of open width fabric at atmospheric pressure,processes such as Bleaching and dyeing at low liquor ratio can be carried out, exactly simulating the bulk production jigger machines. The operation of the Laboratory Jigger is fully automated heating through Temperature controller PC-07 having rate of heating and hold time.The tension on fabric is adjustable to the required levels by the tension control knob.The dye bath and all parts that come in contact with dye liquor are made in SS 316 material. The dye bath is with tapered section to keep the liquor volume low. The fabrics carrier frame is easily removable for cleaning and threading the fabric. A hood with inspection window on the dye bath, keep the liquor losses down.

Infra Beaker Dyeing Machine

Get Price Quote

Infra Beaker Dyeing Machine is designed for dyeing of loose fibers / Yarns / samples in SS pot in very small quantity. It can be substitute for Glycerin Bath Beaker Dyeing Machine (H.T.H.P Beaker Dyeing Machine). As compare to Glycerin bath dyeing machine, Infra Beaker Dyeing Machine avoid the smell of heated Glycerin and heat is directly given to the potS and also measured from pot, so accuracy in process. It is less hazardous and convenient in working. infra dyeing machine heating enables efficient heating of beakers resulting in optimum dyeing conditions. as infrared radiations are used for heating there is no contamination of beakers with messy heating medium and hence the working is cleaner.more dyeing cycles are possible with infracolour as preparation and cleaning time is greatly reduced.injection dosing system is provided for making time to time additions to the beakers without opening the beakers. Variable speed roatation of beaker carriage assembly facilities dyeing of all types of fabric and yarn samples with all classes of dyes. Automation is through microprocessor programmer. Infra colour is environment friendly easy to use sample dyeing machine with infracolour there is no pollution, no smoke or bad smell in working area as is the case with conventional baths. Features • Crease - and spot -free sample dyeing. • Low liquar ratio: 1:5 fabric dyeing cotton. • Soda ash adding without opening the beakers. • No glycerin or coolong water needed. • Optional : Filling in the powder or liquid chemical to be added later on during the dye process. • Three - dimensional movement and 360° rotation (clockwise and counterclockwise) allow even and dyed through samples. • The multi functional beaker holder allows the use of different beaker sizes.

Yarn Dyeing Machine

Get Price Quote

Our company is capable of delivering consignments on time owing to an efficient trading network we have. We have compartmentalized our facility into different units and one of them is packaging unit in which we meticulously pack our products to ensure safe and swift deliveries. Features: Robust design Stainless steel body Abrasion resistant Chrome plated internal parts Different colors on yarn Specification: Saves Chemical, Heat, Electrical Energy Heavy Clamp Locking System

textile dyeing machine

Get Price Quote

Wireless sensor guarantee no maintenance of temperature sensor.(Patents, design register), The dyeing pots are rotated 360° and guarantee even dyeing., - CPU Micro processor DLS-8800.Because the dyeing pot is made by press and special electronic processing instead of trimming it is prevented from contamination and very fit PC, PR, PW, PN due to various pot capacity such as 150ml,300ml,500ml, 1000ml, 2000ml, 4000ml.Laboratory dyeing machines are used in textile dyeing houses and dye manufacturer's laboratories to create sample dyeing. Use of infrared laboratory dyeing machine saves lot of time and cable of creating accurate, reproducible color in production environment.

dew drop machine

25,000 Per Piece

space dyeing machine

Get Price Quote

Since our strict packaging guidelines, we make sure that the products are suitably packed assuring zero damage during transportation. Furthermore, our packaging professionals thoroughly check the whole batch before making the final transmit. We are Bhiwandi(India) based entity and have become a primary choice of the buyers owing to our timeliness. Features : Precision engineered Rugged construction Noiseless operation

padding mangle

165,000 Per Piece

1 Piece(s) (MOQ)

Yarn Dyeing Plant

Get Price Quote

Laboratory Sample Dyeing Machine

Get Price Quote

We are a prominent Laboratory Sample Dyeing Machine Manufacturer, Exporter and Supplier. We are engaged in making available feature packed Laboratory Sample Dyeing Machine. Made from to quality components, Laboratory Sample Dyeing Machine offered by us is precision engineered. Venkteshwara /HP, is a versatile dyeing machine for universal application treating material in various forms, such as packages, muffs, wrap beams, loose stock tops, All Venkteshwara Dyeing Machines are supplied with state of art technology with computerized Dyehouse management in duel versin in Air pad & fully flooded System. Venkteshwara range of Dyeing Machines include laboratory and small production machines. The rage is 1 Kg. to 125 Kg. designed for high operating Temp. 140o C and Pressure 5 bar. All the models have same liquor ratio, functions, specific performance and are of the same modular design. They can be coupled together.All the used for the manufacture of the Dyeing Machines, together with their components and equipment are made of AISI 316 & 316 L stainless steel. Liquor Circulation : Is achieved by means of a high flow rate centrifugal pump with Inverter drive. Variable liquor flow rate is made possible and optimum dyeing results depend upon the type of material being dyed and type of dyestuffs used. With help of inverter drive it is possible to reduce electrical power consumption upto 30% as compared to fixed RPM motor drive. Reversal of Flow : Liquor flow direction is reversed automatically at preset time~ intervals from inside out to outside in vise-verse according to requirement.Material to Liquor Ratio : Programmable and adjustable M:L ratios in rage from 1:4 upto 1:7 are possible. Lower liquor ratio means saving on cost of water, chemicals and energy consumption. The shorter the liquor ratio the lesser the cost of overall dyeing. Air Pad System : By compress air static pressure is obtained and system is pressurized. Material carriers are fully flooded in the dye vat. Variable Loading : A high economic efficiency can be achieved with a constant liquor ratio by simply adjusting the filling level and by using the same material carrier, a smaller amount of material can be dyed. Heat Exchanger : Indirect heating and cooling coil is provided for rapid rise of temperature upto 4 C per minute at steam pressure of 7 Kg / cm2. Heating of liquor is homogenous. Service Tank : A Service tank is provided for feeding dyestuff and chemicals to the dye vat by means of an injection pump. At the top of the tank perforated pipe is mounted for washing of walls. Dispensing System : Linear as well as progressive dosing as per program is possible.Drain : Hot and cold drains have been segregated that installation of heat recovery system is possible. High temperature drain provided so as to eliminate formation of Oligomers while using Dispersed dyes at high temperatures. Rinse : Overflow Rinses provided to remove dirty liquor continuously by having through wash of the material. Carriers : For cone sand cheese,ropes, silver, tops, warp beam sand loose stock with variable loading package carriers. Control System : Fully automatic computerized control system is supplied to increase productivity by reducing production cost & improve flexibility. It offers manual operation, logical functions can done manually Along with the Machine, software of standard dyeing programmed for different type of material is provided or you may feed the new programmed as per your dyeing cycle-Operation by alpha numerical key board or from control panel.Eco-Friendly Machine : Since the pump and Carrier volumes are flooded and low water steam, power consumption and very limited effluents, this, machine is more, Ecology and environment friendly. Venkteshwara manufacturing pneumatic press in duel version 1) Simple Press 2) Motorise Press for package and Top suitable for 25 Kg. to 125Kg. Pressing. Venkteshwara manufacturing all type of HT / LT Panels, PLC Panels & Logic control Panels also under take all type of Electrical turnkey project. Optional Sampling Device.Full capacity preparation tank.Hydro-Extraction in dye- vat.Online PH value measuring and controlling system.Automatic coupling system.Dye Kitchen Equipment.

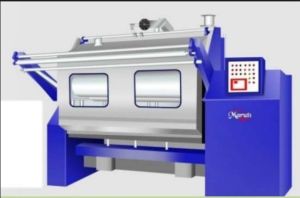

INDUSTRIAL WASHING, DYEING MACHINE

Get Price Quote

TOP LOADING, OPEN POCKET, HEAVY DUTY All Stainless Steel, Inner & Outer, These value oriented units are suitable for all process i.e. Washing Dyeing, Processing, Enzyme, Bleaching etc., available in steam, electric & Thermic fluid hearing, Auto Temperature & water level control through electric steam and water solenoid valves, precisely caliberated sight guage glass, Auto Reverse, Manual pH port with Powerful Gear Box Drive. IDENTICAL RESULTS COUBLE WITH CONVENIENCE OTIONAL-FREQUENCY CONTROLLED DRIVE FOR REQUIRED CYLINDER SPEED

Lab Dyeing Machine

Get Price Quote

In an elegantly designed pilot plant Dalal offers the high-temperature high-pressure version to dye samples of yarn, fibre, slivers of various substrates with suitable material holders. This is very useful for standardizing the recipes of dyeing before batches are taken in bulk. This avoids trial and error methods, thus saving on time, and resources utilized. From the study of the results, it will be possible to estimate production cost and maximize profit margins Salient Features : Fully automatic operation using latest control systems for process sequences and valve operations. Good dyeing of even large packages with high density. Size can vary to receive between 1 to 5 packages.

PADDING MANGLES

Get Price Quote

The INDOFLEX Dyeing Padder is a dyeing and Impregnating machine: An ingenious deflection control principle forms the heart of HARISH INDO-FLEX Dyeing Padder. It allows modulation of expression pattern to achieve desired pick-up. The INDO-FLEX Padder is a dyeing and impregnating padder for pad-dry and pad steam applications. Flexible pressure setting over the width to achieve uniform squeeze throughout the width. The stainless steel cladded inner frame facilitates easy cleaning and long service life.

Cone Dyeing Machine

Get Price Quote

We offer a broad array of cone dyeing machines, which is widely acclaimed due to its advanced technology and superior performance. Checked and tested on set industrial standards, the cone dyeing machine offered by us is the perfect addition to any textile production line for maximizing the profitability while cutting costs.

Laboratory Padding Mangle

Get Price Quote

We offer Laboratory Padding Mangle that is widely used for dyeing, printing and finishing trials. We are a prominent Manufacturer, Exporter and Supplier of versatile range of Laboratory Padding Mangle from Mumbai in Maharashtra. Our varied range of Laboratory Padding Mangle is fabricated from the finest quality of raw material and is strong, durable and corrosion resistant. We offer customized range of this high performance Laboratory Padding Mangle at pocket friendly prices. Features : For Even pressure throughout, pneumatic loading of the bowl is provided.Small unheated trough provided for padding small size samples. Technical Information : Model : Table top Material of Construction : SS 304 & ss 316 Working Width : 450, 600mm. Automation : Microprocessor Controller. Bowl Hardness : 65o – 70o Shore Hardness Bowl Dimensions (450mm WW) : 120mm Dia x 500mm length (600mm Ww) 120mm dia x 650mm length Working Pressure : 4kg/cm2 Cloth speed : Variable upto 6mtr / Min Heated trough's capacity : 900ml Unheated trough capacity : 200ml Electrical supply : 230Vac Single ɸ, 50 hz Approx weight : 150 kg/190 kg dimensions : (450mm) L1000mm x W530mm x H710mm Dimensions : (600mm) : L1180mm x W630mm x H790mm Option : Digital Model for accurate control of Speed & pressure. High Speed and high pressure padding mangle (6kg pressure and speed of 60 meter/minute). 3 bowl padding mangle with central bowl of ebonite or stainless steel. Compensator for use in conjunction wiht drying curing and setting chamber Bowls with silicon coating Nip padding trough and doctor blades for coating purpose.

Open Bath Dyeing Machine

Get Price Quote

Cap : 250ml 12 beaker.Ideal machine for dyeing of fabric, yarn & loose stock samples. Dyeing temperature up to 95°C is possible. Beakers Size Available 100ml or 500 ml, with 12 Beakers.

Dyeing Machines

475,000 Per Piece

dyeing jigger machine

Get Price Quote

Dye Jiggers are your best buy, With latest technical improvements, ‘SHAKTI’ offers most sturdy, smooth and compact designed Jigger, which gives excellent performance under most economical conditions in the processing of light and heavy fabrics like cotton, rayon, silk or synthetics.

FRONT LOADING GARMENT DYEING MACHINE

Get Price Quote

* Available in 90 to 300 kg. capacities.* An efficient Garment/ Knitwear Processor & Washer* A boon to garment / Knitwear manufacturers, exporters & process houses* Carries out desizing, enzyme silicon wash, bleaching, stoning, softening, dyeing and many more* Microprocessor - Pneumatics combines to ensure precise control of time, temperature, level, speed, rotation & process control

Dyeing Machine Controller

Get Price Quote

Used Textile Yarn Dyeing Machine

Get Price Quote

1 unit (MOQ)

Textile Dyeing Machines

Get Price Quote

we are offering you second hand textile dyeing machines ,our textile machineries are available at very competitive prices.

Jet Dyeing Machine

Get Price Quote

Jet Dyeing Machine, Dyeing Machine, mercerizing machine, Stenter Machines

jigger machines

Get Price Quote

jigger machines, Engineering Goods, Engineering Equipment

dew drop machine

Get Price Quote

dew drop machine, Fabric Printing Machine, Sublimation Machine

Yarn Dyeing Machine

Get Price Quote

Yarn Dyeing Machine, Dyeing Machinery, hthp yarn dyeing machine

Yarn Dyeing Machine

Get Price Quote

Yarn Dyeing Machine, Textile Machinery, top dyeing carrier

industrial dyeing unit

Get Price Quote

industrial dyeing unit, filter dryers, Rotocone Vacuum Dryers