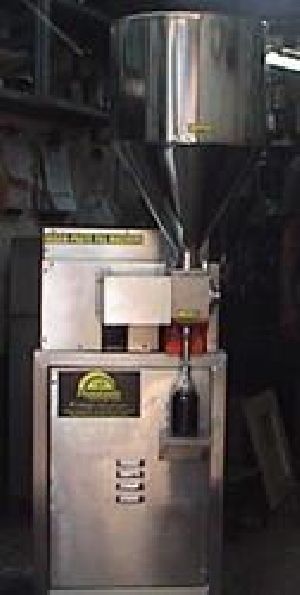

Semi Automatic Paste Filling Machine

jingerpaste filling, garlic paste filling, food paste filling, vinger filling, juice filling, pulp filling,ghee filling, curd filling, dahi filling, icecream filling, butter filling, cake paste filling, mayonnaise filling, yeast filling Ointment : ointment filling, gum filling, syrup filling Adhesives: paint filling,adhesive filling, fevicol filling, paste solution filling, rubber adhesive filling, resin filling, hardner filling, silcon sealant filling Creams : cosmetic cream filling,shampoo filling hair lotion filling,shaving cream filling, mouth freshner filling, hand wash filling, face wash filling, tooth paste filling Balms: lotion filling, balm filling Filling in : bottles, jars, containers, tubes, pouches, tubs, laminates Suitablefill 1gm-5Kg of Paste, Creams, Blams, Ointment, Shampoo, Adhesives, Paints, Food Pastes, Pickles in bottles,Jars, Containers, Pouches. Heavy Duty Piston type filler with accurate weighing Also available in Hot jacketed filling unit for hot filling Available in Single Head-Double filling nozzles Can be add conveyor with stopper for automatic handling Volumetric filling Drip free nozzles for clean cut off uring filling Stainless Steel 304 or 316 grade contact parts 25Kg product storage hopper Heating arrangement in hopper for hot filling process Easy adjstment of filling by hand screw Foot Operated or Auto set operation +/-1% filling accuracy Can be synchronized with conveyor and stopper Power:220V, Single Phase/ 2KW Speed: 15-50 Bottles/Min

...more

Semi Automatic Liquid Filling Machine

Liquid filling machine is a machine that was specially developed in order to fill high viscosityliquid products such as shampoo, lotions, oils (motor oil and cooking oil), etc. Liquid filling machine is majorely used for filling free flowing liquids. Liquid filling machine also known as liquid filler and liquid dispenser which is suitable to fill 1ml to 5000ml of any liquid in bottles,cans,jars,tubs Liquid filling is automatic filling machine runs of volumetric filling principle. Liquid filling machine is widely used for milk filling, bottle filling, jar filling, container filling, oil filling,ointment filling,shampoo filling, juice filling, liquor filling, perfume filling, wine filling, can filling, food product filling. Liquid filling machine is also known as liquid dispensing machine Filling by liquid filling machine is completely drip free and accurate in weight. Liquid filling machines are mostly used in pharmaceutical filling & food filling as a filler or dispenser Desired speed can be achieved by liquid filling machine bu adding filling heads Major liquid fillers are available in 1,2,4,heads Liquid Filling machine can produce 10-40 bottles per minute by adding maultiple heads to filler head Vineger filling, perfume filling are used in liquid filling machine . Semi-Viscouse liquid can be accurately filled by liquid filler machine Suitable to fill 5ml-5Lit of Liquids in Bottles,Pouches etc. Compact Machine Accurate filling of the product Drip Free filling with diving nozzles Available in single, double heads +/-1% of filling accuracy

...more

Semi- Automatic Capping Machine

These machines aredesigned for sealing bottles and containers with closure of variousshape and size. Our semi automatic capping can be configured for manytype of closure such as aluminum roll on closure and plastic flat screwcaps. These machines are very simple to operate, by adjusting stop andoperation height the desired packaging and closure size can beachieved. These machines are high in performance and provide longservice life.

...more

Automatic Powder Filling Machine

Automatic Powder Filling Machine Suitable for filling 1gm-5Kg of powder in bottles, Jars and Containers Auger type filler, Clutch-Break Mechanism (Optional Servo driven) Available in Single Head/Double Head Filling nozzles and 4 Feet Belt Conveyor Accurate Weighing with Weigh scale below Filling nozzles Pneumatic Bottle Stoppers 2HP-Mechanical Motor drives Variable speed conveyor drives PLC Based Control Systems /-1% Filling accuracy SS 304/316 Contact parts MS/SS Covers Available in GMP Model Semi Automatic / Automatic Powder Filling Machine offered by us are designed to deliver optimum functionality in given operations. These find application in areas like Pharmaceuticals, Food Supplements, Food Colours, Powders, Tea, Coffee and Talcum Powder. Features: Automatic Powder Filling Machine Suitable for filling 1gm-5Kg of powder in bottles, Jars and Containers Auger type filler, Clutch-Break Mechanism (Optional Servo driven) Available in Single Head/Double Head Filling nozzles and 4 Feet Belt Conveyor Accurate Weighing with Weigh scale below Filling nozzles Pneumatic Bottle Stoppers 2HP-Mechanical Motor drives Variable speed conveyor drives PLC Based Control Systems /-1% Filling accuracy SS 304/316 Contact parts MS/SS Covers

...more

Resin Filling Machine

Paste Filling Machines offered by us finds application in the filling of Honey, Vinegar, Fruit Syrup and other products. The machines can fill paste in bottles, containers, jars, tubes, tubs, pouches, laminates and others.

...more

Pneumatic Perfume Crimping Machine

Perfume Bottle Crimping machine is a single head machine, which is the higher version of Hand operated Perfume Crimping Machine. Based on the highest efficiency factor, we have taken a lead from the existing manufacturers and Exporters Characteristics Suitable for small, medium and lab purposes Very much useful, where there is less human labor is available The operating strength of human hands for crimping is replaced by a pneumatic cylinder So, ladies can also easily operate this machine for long time Machine Structure and working Made from Mild steel for main body and structure The tool is made with special material which is machined and hardened to get the correct crimping each time Operating of this machine is also very much simple A pedal operating foot switch is provided with the machine to do each crimping When once pressed, a single crimping is done with perfect tight The foot switch is very soft to operate Specifications Number of Collets: 1 Single Head. Can Crimp Perfume Bottles and other similar bottles Crimp cap range: 15mm – 32mm at a time as per collets (Tool) size. Output: 25 crimped bottles per minute depends upon labor skill. Machine type and Model: Pneumatically operated Perfume Bottle Crimping Machine (DEPBCP 16) Crimp Tightness adjustable by setscrew on the collets GMP Models also available Semi-automatic Pneumatic Machines also available on request Automatic Filling and Crimping Machines are also manufactured by us as per customer specifications Special Features Machine is small in size and can be carrying with hands To add a FRL unit (fluid regulator and liquid sump) with the compressor to avoid, humidity and water going to pneumatic fittings Each machine is provided with a pneumatic pressure control unit with which we can adjust the air pressure required for usage Machine is having a bottle resting platform, which is spring loaded The machine is compatible with 16mm tool, or 20mm tool as per production requirements This enables the bottles to tightly press towards the tool during crimping. (optional attachment can be a pneumatic cylinder for clamping the bottles to the tool at extra cost) Tool tightness to the neck can be adjusted as per bottle neck variations When once the bottle is rested and clamped, the only operation manually done is to press the pneumatic pedal switch Our standard machines comes with polyurathene tubes and push in fittings Each pressing and release will do each crimping adjustments for heights as per various bottle sizes can be done with the crimping head, by unscrewing, adjusting and tightening the hand lever at the back side on the head Pneumatic Crimping Machine is having a pu8 (that is 8mm outer diameter and 6mm inner diameter tube), tube; accordingly, you may have to fit the connection on the compressor Any sizes of crimping tools from 15mm to 30mm can be supplied from us at extra cost. Maximum net weight for the machine will be 20 kgs Normally, the compressor comes with 1/4" BSP fittings The packing size will be 23" l x 10" w x 14" b. the gross weight including wooden case will be 30 kgs

...more

Pneumatic Paste Filling Machine

series machine can simply called as a perfect filling machine or a multi-purpose filling machine. In this machine, we can fill from liquids to hard paste material without changing any parts. A very user-friendly model with low maintenance requirement. This machine is the upgraded version of ordinary semi-automatic Motorised Paste filler. Here, All filling operations are done by Pneumatic Cylinders. Less rotating/ moving parts means low maintenance. Machine Structure and Working: Complete Filling machine unit is mounted on a strong frame structure with a top plate. A horizontally assembled Piston Barrel unit attached to a Pneumatic Cylinder is the main part of this machine. Other parts are, A rotary valve actuated by a pneumatic rotary actuator/CYLINDER, and a volume adjusting screw. A separate panel box is provided with the machine to perform all the operations in sequence. A pedal operating foot switch is also given to do each filling. A cut-off drip free valve can also provided as added facility to stop dripping during filling. When the mains are ON, the only operation manually done is to place the bottle/container under the fill nozzle, and to press the foot switch. A perfect measured filling is occurre Special Features: Complete GMP Model suitable for Pharma Applications and food industries. Clean filling without dripping, Any material from free flowing liquids to hard pastes can be filled by same machine. Cras justo odio High accuracy in each filling. Container resting Platform provided Separate Panel Box with all control switches away from fill area. 1)SPECIFICATIONS For Semi-Automatic PISTON filler Pneumatic Machine 2)Machine Model: Semi-Automatic Honey Filler Pneumatic, DYPF1100 3)Machine overall size; 3.5 ft L X 1Ft W X 2.5 Ft H 4)Machine weight: 50kgs approx. 5)All Material contact Parts are in SS316 grade, finished to mat. 6)Fill Barrel size: 65mm Bore X 180 Length(For1000gms filling) 7)Output: 12-16 fills per minute with bigger nozzle. 8)Fill Capacity:100gms-1000gms as per barrel size 9)Compressor required: 5.5 Kg.cm2, 3 cfm. 10)Inbuilt Panel Box with timers switches and valves. comes with this machine. 11)Adjustable stroke and fill volume with a hand wheel provided with the machine.

...more

Planetary mixer

The homogenous mixing at various ingredients of different densities in different proportions for solid/solid, liquid/ solid, and liquid, which is achieved effectively by the use of Planetary Mixer (Model No: DEPL50 and DEPL100) Vacuum Jacketed Planetary Mixers for the preparation of ointment; toothpaste; creams; suspensions are designed to achieve the best results All contact parts are made from SS 304 or SS 316 steel as per client's requirements. Standard Mixer is available in 50, 100, 200, 350, and 600 liters capacities

...more

Perfume Filling Machine

We manufacture a versatile filling machine for volume filling applications. The machine is called Vacuumetric filler. Very useful filling machine designed for Alcohol, perfumes, and distillery industries. Here, the machine works on the basis of Vacuum suction from the container. Fast filling of any Glass bottles can be done by using this machine. Various volume can be filled by adjusting the height of Bottle holder and by adjusting the vacuum filling nozzle. Machine Structure and Working Complete machine frame is made from Mild steel Angle structure, welded, and finished with polymer. Total Frame structure is covered by stainless steel sheet metal of good gauge and finish. A ¼ HP 230VAC self cooled Vacuum pump is providing the vacuum required during filling. This unit is mounted inside the frame with cover , so that the noise is maintained to a minimum during working. All the other parts like, liquid overflow trap, fill nozzles, are mounted over the frame structure. All material contact parts are made from stainless steel 304 quality or 316 material as per specifications. A trap vessel with suitable capacity is mounted at one side of the top to collect the overflown liquid from the bottles. Fill nozzles are comes in pairs like, 2, 4, 6, or 8 as per fill requirement. Various fill volumes can be filled at a time as per adjustment. Also, the fill nozzles are capable to tilt to upto 90 degrees for easy filling. Machine is easy to operate. The glass bottle to be filled is to be pressed towards the fill nozzle, where a gasket is provided. When the bottle is vacuumised, the liquid is filled fast into it. The fill level is maintained as per the nozzle height adjustment inside the bottle. No maintenance is required since, there is no moving parts is involved. Most economical for level filling applications. Special Features Strong model with complete stainless steel mirror finished covered body All product contact parts sre made of stainless steel 304/316 quality High speed filling No dripping or wastage of liquids because of vacuum and trap vessel Multiple tiltable heads provides easiness in filling Bottle resting platform with height adjusting facility Easy to operate Any volume can be filled from 5ml to 1 liter as per required Specifications Machine size : 400 X 400 X 1400 mm H Machine weight : 50 kgs Approx Number of heads : 2 /4/6/8/12 Machine name : Multi Head Vacuumetric Liquid filling Machine Output : 20 fills per minute from each head Power consumption : 0.5 KWH Electricity required : 1 phase 220 VAC. 50 Hz Vacuum pump : ¼ HP 25 LPM All material contact parts are in SS 304 Tilt able nozzles Base for bottles provided Inbuilt vacuum pump and closed type High efficiency machine 10 liter capacity overflow vessel attached Easy to operate Low maintenance model Fill capacity from 10ml to 200ml Uses : Most suitable for filling any free flowing materials like, liquor, syrups, perfumes, etc.

...more

Perfume Crimping Machine

the most trusted name in the field of manufacturing and supplying of Perfume Bottle Crimper. We are reckoned in the global markets for the manufacturing of precision-engineered Perfume Bottle Crimpers, which are widely asked by industries. To satisfy the varied needs of industries, we are offering them in a wide range, which is flourished with many efficient features. Offering perfume Bottle Crimping Machines. This machine is widely used in Perfume industry, where small and medium scale production is required. If there is more production required, and if it is more human labour available, then also this machine is suitable. Machine type is Manual operated and it is very simple to operate. Bottle with cap, to be crimped has to be placed under the crimping tool, where a spring loaded Platform is provided with spring load.

...more

Paste Filling Machine

Automatic Paste Filling Machine is the prime manufacturing product of Dynamic Enterprises, which are reckoned in the global markets for their efficient features. Based on that, we have earned a load of credentials and statured as the prime manufacturer and supplier of Automatic Paste Filling Machine.Any semi-skilled operator can start this machine and run by him with a small training,The only operation is to start the switches and to feed the bottles as per filling progress,Hopper is also having a top lid with hinges to enable product feed.

...more

Packing Belt Conveyor

Packing Belt Conveyor offered by us are made available in different range options and are well recognized for delivering optimum performance. Being extensively being used for applications of conveying & transferring, these handle empty, filled bottles, containers, jars as well as other items on packaging line. Some of the features of Packing belt conveyors include: Application: Conveying & transferring of empty/filled bottles, containers, jars as well as other products in packaging line Construction: M.S. Silver painted (S.S. option available) Belt: 9" / 12" / 18" PVC Coated canvas / Rubber belt (Imported food grade belt also available) Height: Adjustable (as per requirement) Speed: Variable Power Requirement: Depends on length

...more

Labeling Machine

Less power consumptionSmooth functioningHigh performance Other Details: High production speeds up to 150 per minuteUnrivaled build quality and reliabilityPLC or micro processor systemEquipped with printing deviceSuitable for Glass, Plastic, Pet, Tin, Corrugated containersS.S. elegantly matt finished bodyBatch-coding thermal inkjet type printer to be provided Specifications: Output Up to 150 containers Electrical Rating (A) 0.25 HP / RPM Motor for Conveyor Drive (B) 0.25 HP / 1400 RPM Motor for Pressing Device Drive (C) 6 V DC stepper motor Power Characteristics 230 Volts AC 50 Hz Construction Top stainless Steel matt finish & S.S. Pipe structure is covered with S.S. 304 sheet Overall Dimension 1835 mm (L) 600 mm (W) 1250 mm (H) Conveyor Height 800 mm 50 mm Input Specification (A) Round container dia: 25 mm to 80 mm (B) Label: 30 to 180 mm (L) 16 to 100 mm (W) Label Roll Diameter

...more

Juice, Wine Filling Machine

Accurate filling with piston/pump base filler unit Suitable for wide range of liquid characteristic with high viscosity Volumetric mechanical/touch screen control for achieving easier graphical user interface Automatic stopping of machine system by detecting shortage of bottles Accurate filling with /-1% fill accuracy Drip Free Nozzles Automatic stopper mechanism Available in various filling systems as per product flow characteristics Easy cleaning up and low maintenance Can be supplied with complete filling-capping-labeling lines Applications: Pharmaceutical liquids Chemical liquids Cosmetics Lotions Shampoos Sauces Syrups Oil Beverages

Production Capacity : 10

...more

Induction Sealing Machine

High sealing speed that makes them suitable for volume-production Convenient for use with good sealing quality and working continuously Ejection plastic iron housing option SF-3000B Production line Automatic Electromagnetic Induction Aluminum Foil Sealing Machine Feature: Digital display for working voltage and current, clear and intuitive Over-voltage, over-current automatic protection, safe and reliable high sealing power, high quality, stable performance can used in production line or work independently full 202 stainless steel with surface finishing and special treatment which ensure good quality and artistic appearance Application: Sealing for PET bottles, PP bottles, PVC bottles, PE bottles, HDPE bottles, plastic bottles, glass bottles, etc Widely used in cosmetic, drinks, chemical, medical, food industry etc, which can highly improve productivity and product quality.

Voltage : 220V, 50/60Hz N.W. / G.W. 72KG / 120KG

...more

Hydraulic High speed mixer Machine

We offer Variable Speed Dispeser from 100 to 2000 Ltrs per batch with variable speed / hydraulic lifting & lowering arrangement in Flame proof or TEFC drive. Quantity : 1 Set Payment Terms : L/C (Letter of Credit),T/T (Bank Transfer) Port Of Dispatch : Mumbai Production Capacity : 50 Delivery Time : 8 weeks Packaging Details : Wooden case

...more

Hand Operator Paste Filling Machine

Paste filling machine with high output abilities and most economical in the range of paste fillers. Machine is suitable for starters with low budget and higher filling needs. This machine comes in all- in- one type with a strong bracket, a hopper, a fill barrel- piston (syringe) arrangement, and a hand operating lever. A set screw is provided in this machine to set the required fill volume. High accuracy in filling can be achieved in this unit. Fill output can be varied from 15 fills to 20 fills according to the operator skill. Here also the syringe comes in different sizes as liquid filler. An inbuilt hopper of 5 liter capacity for small machine, and 20kgs capacity hopper for bigger fill volume with cooling jacket is also provided with the machine . Table top model weighs less than 20 kgs and operating is very easy. All the material contact parts are made in ss304. The machine can be mounted in a space less than 12" x 12" space. the lever is extended outwards from the machine towards the operating lever but at a height.

...more

Hand Operator Liquid Filling Machine

AEHVF Model machine is small, compact and light weight. Total weight including syringe is only 16 kgs. So, the packing size is also less. There are many syringes you can select as per your requirement. The syringes are for filling volumes like 10-25Ml, 25-50Ml, 50-110Ml, 100Ml-260Ml, 250Ml-500Ml,100-1000ml etc. Machine comes in standard Polymer/ powder coated or GMP models available as per order.

Machine Weight : 20 kgs.

...more

Fully Automatic Tube Filling Machine

Tube Filling Sealing machine is easy to Operate & compact in its design Tube Sealing Machine Can we available in both Cam Indexer as well as Geneva Mechanism with changeable tube holding unit for variable tube size. The Filling Block and filling syringe which is made in Stainless Steel is arrange in such a manner that it prevent tailing of product to be filled. The Capacity of Simple Stainless Steel Hopper is of Twenty-Five Kilograms. This machine has hot air system for best quality sealing which is imported from Switzerland. Tube Sealing Machine comes with one hot air nozzle with basic M/c. The machine production speed is 30 to 60 tubes/min. The operator just needs to load the tube in the tube holder after that tube is automatically filled , sealed with ultrasonic heater, batch coding and trimming is done after that tube is automatically ejected. Auto Tube Filling Sealing machine is compatible to seal both Lami as well as plastic tube. Description Tube Filling Sealing machine is easy to Operate & compact in its design Tube Sealing Machine Can we available in both Cam Indexer as well as Geneva Mechanism with changeable tube holding unit for variable tube size. The Filling Block and filling syringe which is made in Stainless Steel is arrange in such a manner that it prevent tailing of product to be filled. The Capacity of Simple Stainless Steel Hopper is of Twenty-Five Kilograms. This machine has hot air system for best quality sealing which is imported from Switzerland. Tube Sealing Machine comes with one hot air nozzle with basic M/c. The machine production speed is 30 to 60 tubes/min. The operator just needs to load the tube in the tube holder after that tube is automatically filled , sealed with ultrasonic heater, batch coding and trimming is done after that tube is automatically ejected. Auto Tube Filling Sealing machine is compatible to seal both Lami as well as plastic tube.

...more

Fully Automatic Paste Filling Machine

Automatic Paste Filling Machine is the prime manufacturing product of Dynamic Enterprises, which are reckoned in the global markets for their efficient features. Based on that, we have earned a load of credentials and statured as the prime manufacturer and supplier of Automatic Paste Filling Machine. Used For Multiplying the output of any filling unit Technical Specifications Viscous or non-viscous products can be accurately measured and filled in any shaped containers or bottles or even tubes with this machine Special facility to increase and decrease the speed An output of at least 80 fills per minute with this four head machine. Models in this series are also comes with two heads and 6 heads Operating A operating panel board is provided for the operator at a height on the machine There are very few switches to operate this machine Any semi-skilled operator can start this machine and run by him with a small training The only operation is to start the switches and to feed the bottles as per filling progress When once the fill volume is set it is fixed till it is not changed manually Hopper is also having a top lid with hinges to enable product feed Specifications for Automatic Paste Filling Machine Machine size : 8 feet L X 6”W X 5 feet height Total machine height : 5 feet including Hopper/li> Machine weight : 285 Kg approx Conveyor motor : 1/4 Hp Variable speed AC Motor 3 phase Power Consumption : 1 KWH. Maximum Air Consumption : 18 CFM.( 3HP Twin Cylinder Air Compressor) Automatic Paste Filling Machine Fill range : 10 ml- 100ml each.(4 Heads) Fill accuracy : +/- 1 % Output : 60 Filled tubes per minute All material contact parts, Cover, Frame cover, are in S.S.304 quality Mat finish Stainless steel 304 piston type filling Conveyor Indexing by Screw Mechanism Panel box with Electrical switches and control units Properties Very reliable Counting sensor for tubes High output is the main motto Screw type indexing for bottle Particular sequence in this machine gives a feeling of a good orchestra performance during a concert Complete feeding and filling done linearly over conveyor High efficient machine parts Batch counting possible when once started Perfect engine to deliver the best Completely pneumatic operation, so maintenance is low High output Diving nozzles ensures internal filling without damaging the mouth Very less maintenance to reduce the downtime of the machine Cut off valve provides drip-free filling Each part is selected from the highest quality material Stepper drive for bottle indexing gives high accuracy Assembled under the supervision of our highly qualified engineers to get the maximum finish of work Complete GMP standards Fill quantity adjustable as per requirement Manual and automatic function provided Automatic shut-down of machine when not in use High accuracy in filling with piston filling No-bottle- no- fill facility Stainless steel covered body. Machine Structure and Working Main frame is fabricated with Tubular structure A strong top plate to take all the mechanical and pneumatic forces of the machine Complete electronic parts are placed in a separate panel box to avoid any material contact with the product All the machine parts are keeping GMP standards The main parts over top plate are Filling barrel with valves, Pneumatic assembly, A product hopper, etc A long conveyor is mounted at the front side of the frame structure, which holds and moves the empty and filled containers to and from the filling area Container/tube indexing is done by a screw and filling is done with diving nozzles Diving nozzles assures drip free filling of viscous products. Stepper drive ensures the accuracy of bottle indexing each time All the valves from product suction to drip free valves are operated by Pneumatic actuators to get a positive and clean working Facilities like easy cleaning, and product change, Fill adjustment , automatic shutdown when not in use , batch counting facility are added features of this machine

...more

Fully Automatic Liquid Filling Machine

To hold and index the bottles, a frame structure, a vibratory cap feeder, and drive mechanism Filling liquids in bottles on continuous running S.S. Slat conveyor Accomplished with Input and output conveyors Flower wheel (Turret) arrangement Separate panel box Control switches Industries Cosmetics industries Pharmaceutical industries Herbal industries Chemical & Food packaging industries Bottle or containers Machine conveyor etc Technical specifications Bottles are collected and moved to the filling station from the conveyor by a turret wheel Electricity required: 1 Phase,220VAC,50Hz, 1.5 KWH Filling station, filling of required volume is done accurately Output: 20 containers per Minute The turret holds and indexes the filled bottles to a cap placing station Fill range 25ml to 100ml Vibratory cap feeder controls the orientation of the caps and feeds to a chute, which leads to the capping station Labor required : 1 semi-skilled operator When the bottle comes to the station, each bottle is placed by cap and ready to tighten Separate control Panel with control switches During the next indexing, tightening of caps to the required strength occurs Works on volumetric principle and used for filling liquids in bottles on continuous running S.S. Slat conveyor Tightening station can either screw capping or press capping according to the requirement of customer Single or Multiple bottles can be filled at a time with predetermined volume After tightening, the flower wheel indexes and the capped bottles carried to an outlet conveyor for final packing Fixing appropriate size of the syringes can fill different capacity bottles in a particular time Clutch Brake assisted filling for sudden start and stop A specially designed synchronized Mechanical movement with the conveyor system and bottle-indexing mechanism ensures smooth running of the machine No-container-No fill-No-cap facility A NO BOTTLE NO mechanism prevents spillage of liquid when the continuous flow of bottle is not available Cap feeding by Bowl feeder/vibratory feeder The unit is designed to fill aseptic liquids with precise accuracy and can give output of 40-60 bottles/minute for double head depending on quality of bottle and fill sizes Cap pressing/cap tightening at separate station

...more

Carton Overwrapping Machine.

This machine is for over wrapping and sealing of rectangular cartons with cellophane or BOPP film. The film kept in Rolls are cut to correct size, wrapped over cartons and heat sealed. Power consumption is 2.0 kW. The machine has output upto 7000 cartons/hr depending on the size and shape of the cartons. This machine is suitable for overwrapping rectangular shaped cartons like eraser, condoms, cassettes, blade dispensers and other rectangular cartons used in perfume, cosmetic, food, pharmaceutical and similar industries.

...more

Carton Overwrapping Machine

This machine is for over wrapping and sealing of rectangular cartons with cellophane or BOPP film. The film kept in Rolls are cut to correct size, wrapped over cartons and heat sealed. Power consumption is 2.0 kW. The machine has output upto 7000 cartonshr depending on the size and shape of the cartons. This machine is suitable for overwrapping rectangular shaped cartons like eraser, condoms, cassettes, blade dispensers and other rectangular cartons used in perfume, cosmetic, food, pharmaceutical and similar industries.

...more

Brush Bottle Washing Machine

semi automatic bottle brushing and washing/rinsing machine is suitable for all kinds of bottles, vials, jars etc. It consists of following units. brushing unit: available in 2 or 4 heads. Have ss covered body and robust construction. Rotating chucks are provided to hold the brushes of suitable size for brushing the bottles. rinsing unit: each unit is made out of ss304, consists of 12 ss rinsers. Valve is provided for controlling flow of water. Leak proof construction. Whole unit is constructed over a drainage tray to avoid spillage of water out of tank. Rubber corks are provided over rinsing tray to avoid chipping of bottles. ss tank with sink: brushing and rinsing units are fitted on the ss tank. Waste water is stored or can be drained out by using sink. The whole structure is made out of 16 gauge ss. motor drive: 1hp, single phase. output: up to 30 bottles with 2head, 1 rinsing unit.

...moreBe first to Rate

Rate ThisOpening Hours