WRINGER WRINGER INDUSTRIAL MIL ROLL ROLL

NCCM Mill Rolls are slightly compressible with a porous open surface. With the compressible, sponge-like characteristic, the rolls conform to the smallest variations in gauge thickness to maintain consistent tight contact across the strip. This tight contact helps assure exceptionally uniform wringing. Strips emerge drier from the rinse tank, and in some cases, users have found up to a 50 percent reduction in solution “carry through” compared with conventional rubber rolls. And the porous surface absorbs fluid to greatly reduce the chance of hydroplaning which can cause slippage.

...more

Squeezing Roll

NCCM Mill Rolls CX and CX-Plus are specially engineered to perform in aggressive chemical environments, such as electrolytic lines for tinning, chroming or galvanizing; or on pickling, caustic cleaning or coil coating lines. Recommended Applications Recommended Production Lines Wringer rolls in acidic & caustic environments Hold-down rolls Deflector rolls Steering rolls Pinch/feed rolls Submerger rolls Electro plating lines Pickling lines Color coating lines Caustic washers

...more

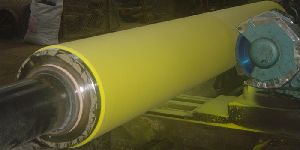

POLYAMIDE SLEEVE ROLL

Advantages of Imported Polyamide Sleeve ECK Haubold & Laxmi’s sleeves are centrifugally cast, guaranteeing perfect quality due to exceptionally high revolving speed (2000rpm) utilized in the casting process. This high speed “spin casting” ensures the expulsion of all air bubbles & impurities from the cover. The natural atmospheric cooling of the cast polymer in the molding process ensures the maximum reaction time; allowing longer molecules to form on latest computer controlled equipment not extruded which is old technology. Extruded is subject to use internal stresses leading to shot molecules and distortion of sleeves after certain time say 4-5 years. The optimized molecules length gives sleeve roll cover its excellent elasticity & mark recovery with minimum shape distortion. This results in excellent runability in the calendar & maximum service life. Internal stresses are minimized as it is produced at temperature below the melting point of the polymer. Polyamide sleeve are finally annealed the ultrasonically checked, guaranteeing optimum quality & performance. Higher hardness combined with better elasticity Higher thickness of sleeve compare to the available sleeve in the world. Spun casting construction is the advance manufacturing process adapted to casting the sleeve. Proper, specific and best quality material used for casting the sleeve. Higher resistance to selvedges and sewing seams Much better smoothing & finishing effect then the available sleeve in market Maximum linear pressure 350kg/cm =1955lb/inch. Maximum speed 200 m/min=650ft/min. Maximum temperature on the surface of the metallic roll 220c=428F Manufactured on solid ultrasonic tested one piece shaft. Surface finish of the Roll is done with high grade and imported tool, & especially designed Micro Film Polish paper for the polyamide surface finish only. Dimension accuracy is maintained as per set standard by our German principal.

...more

OILING ROLL

With tight contact, NCCM Mill Rolls meter and apply lubricants consistently and uniformly. And operators can remove excess protectant oils on incoming metal strip. This “de-oiling” helps reduce costs and improve capabilities in the caustic cleaner. For more information on oiling and de-oiling, please refer to the relevant NCCM application notes.

...more

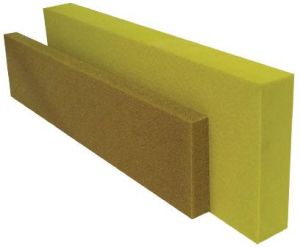

MILL WIPES

NCCM Mill Wipes are a unitized bar product that is made of laminated non-woven web. NCCM Mill Wipes are similar to NCCM Wiper Bars except that NCCM Mill Wipe products have a softer density. NCCM Mill Wipes are designed to replace felt, rubber, and other traditional wipe materials in applications where fluid control, oxide/debris removal, and a non-abrasive cleaning surface is important. NCCM Mill Wipes have superior oxide retention abilities compared to other traditional wipe materials. NCCM Mill Wipes layered construction offer the ability to remove the used layer to expose a clean work surface.

...more

LAXMI HELEXTRA ROLL

To more than 50 years Eck Haubold & Laxmi has offered Textile and Paper industry outstanding services in the field of surface finishing. As a part of expansion programme we developed a roll with unique feature of high efficiency liquid extraction. LAXMI HELEXTRA2 is the latest development in Squeezing Technology assuring greater efficiency, substantial cost & energy saving. Our customers will appreciate HELEXTRA'S potential of tremendous cost saving as many application, it can bring remarkable payback and cost of the Roller will be recovered unbeliveable within few months. ECK HAUBOLD is first to manufacture non-woven Laxmi helextra roll in the country and is much superior than an ordinary rubber roll. the squeeze-off effect is nearly 50% more, depending on the type of fabric to be processed, using 30 - 50% less energy. That means significant saving in subsequent drying process, resulting improved productivity by increased mangle speed. In many cases it is also possible to work wet-in-wet where by intermediate drying operation can be omitted. Such a unit pays for itself within short span of working because of immense saving in drying energy cost as well as saving energy. In operation LAXMI HELEXTRA produces a powerful squeezing action and provides cappilary suction. The fabric passes between the nip of LAXMI HELEXTRA and hard roller. the liquid is squeezed by hard roller, and extracted out by LAXMI HELEXTRA roller when compressed. Fabric still in the nip regain its shape, draws air through the fabric in to the capillary and create sucking action which removes much of the liquid from the fabric as shown in the diagram. the recommended nip line pressure is 30 - 50 Kg / cm for excellent results.

...more

Hard Chrome Plated Roller

ECK Hard Chrome Plated Metal Roll Hard Chrome Roll is known in many names Such as Heating Roll, Metal Roll, and Finishing Roll Hard Chrome Plated Roll. ECK Hard Chrome Roll is a vital part of Calender Machine, The Finish is the mostly depends upon the Metal Roll or Hard Roll. These roll provide the best support to elastic rolls or soft rolls , the nip is formed with the combination of elastic roll is responsible for the finish on fabric or on paper or any other media which are being to pass through the calendering process. ECK Hard Chrome Roll stands tall in all quality and Operational Parameters. Why Hard Chrome Plating Needed? Hard Chrome Plating on the Metal Roll provides the Excellent finish on the Calendared product due to its Superior Mirror Finish. Chrome Plating Provides Wear Resistance, buildup of surfaces, rust prevention or chemical resistance (and superior friction qualities),

...more

cotton roll

Superfine Bowl Filling (a) Cotton Bowl for Textile CalendersCX - Combination comprise of conditioned, carded carefully laid cop bottom superfine cotton material. (b) Cotton-Comber bowl for super calender (Paper Industries)CXI - Combination comprise of conditioned, carded and carefully lad blend of superfine cotton and cop bottom material homogeneously mixed. Cotton material is well built in lap/cake form under hydraulic pressure for filling. Seasoning of cotton cake under controlled temperature and humidity is a unique feature

...more

High Expression Squeeze Roll

Be first to Rate

Rate ThisOpening Hours