woven sacks printing machine

Corona treatment for woven sacks-PP/HDPE Woven sacks fabrics has to be corona treated before printing on flexographic printing machine. Corona treater for woven fabrics-Corona treatment system is a very effective way to increase the surface tension of virtually any material. Surface treatment is required for plastic films/fabrics whose normal surface tension is not sufficiently high to permit good wetting by flexo graphic inks. Application : Blown film extrusion single and multilayer for plastic film plants Woven sack roll on- line Flexo printing machine. Extrusion and lamination coating plant for paper industry Sheet line plant Plastic moulded articles Woven sack roll on line flexo printing machine Gum coating on PTFE coat fibre glass cloth PVDC coating on PVC film for pharmaceutical applications.

...more

Woven Fabric Corona Treater

Warranty : NA

Water Cooled Induction Cap Sealer

Eltech Engineers offers on line automatic cap sealing systems for high speed cap sealing applications. This Induction cap sealer consists of the high efficiency and microprocessor control panel , induction head unit & efficient water circulation system. This system requires water cooling and is available with or without conveyor. This Induction cap sealer can seal containers having diameters from 10mm upto 63mm production speeds upto 80 bottles per minute. No wad detector system. Foil liner / stalled bottle detector. Total production counter. Conveyor stop system. On line conveyor with variable frequency AC drives.

...more

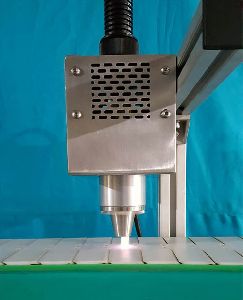

Vortex Plasma Treatment System

Eltech's New Vortex Plasma treatment system is built around the concept of a high voltage Plasma discharge in atmospheric air while the plasma head is rotating. The versatility of this unit allows for use in fully integrated on robots, as a standalone unit, or any production line for covering more treatment area as the treatment head diameter is larger & rotating. The purpose of surface treatment of polymer based materials is to increase surface wettability through plasma discharge. The low surface energy of polymer based substrates often leads to poor adhesion of inks, glues and coatings. To obtain optimum adhesion, it is necessary to increase the surface energy of the substrate to just above that of the material to be applied. Surface treatment with plasma results in improved surface adhesion properties. Eltech offers a cost effective method for optimising the adhesion properties of printing inks, coatings, glue, paint onto a polymer surface including commonly used materials like polypropylene and polyethylene. This universal system developed by Eltech operates with special rotating DC motor for spinning Plasma Nozzles pointing inwards for uniform treatment and to minimize heat impact & Cover larger area. The system is able to rotate up to 3000 rpm / min. These self contained units can be installed within existing production lines or used as an off line process. The system includes a high frequency generator, high voltage transformers, rotary plasma heads and customised stand alone or bench top treating station. To ensure proper Plasma Discharge from the Discharge Nozzle the compressed air must be within a certain level of pressure and volume. Eltech’s Vortex Plasma conforms with CE regulations and is CE marked.

...more

Vaccum Plasma Treatment Machine

Eltech's Laboratory Vaccum Plasma unit is portable, small enough to fit onto a bench and is a cost effective solution to the problem of improving surface wettability. The lab vacuum plasma unit is very simple to install and can be operational within minutes.It comes equipped with its own vacuum pump. Featuring operator friendly & easy to learn and use. The see-through door enables you to see your parts being treated in the large chamber. All of the key parameters are adjustable (i.e. treatment power, time & vacuum level) allowing you to achieve total process control. Eltech Engineers supplies plasma solutions to improve the surface energy of plastic and rubber components to ensure good adhesion of printing inks, paints, adhesives, coatings etc. and for the surface cleaning of plastic, rubber and metal parts. Plasma surface modification equipment is widely used throughout a diverse range of industries and onto an ever increasing range of substrates. Our growing list of customers includes many in the following industries: medical, automotive component, electronics, cable, pipe and many more. Through our many years of experience and continuous product development we have become one of the leading suppliers of Plasma Surface Modification equipment, Eltech Engineers is here to help you find the most appropriate surface modification technology and equipment to solve your problem. How Could Vacuum Plasma Treatment Benefit You ? Vacuum Plasma provides innovative surface modification technology and offers effective solutions to adhesion and wetting problems in many industries. Component preparation using plasma treatment is an important step prior to printing, bonding, painting, varnishing and coating processes.Plasma surface modification provides an economical solution for the cleaning and activation of part surfaces before further processing. How Does Vacuum Plasma Treatment Help To Solve The Problems Of Adhesion ? To obtain good adhesion to low surface energy materials i.e. low or non-polar materials like PP, PE, HDPE etc. we need to modify the surface i.e. increase its polarity. Placing your components in the highly active environment that exists inside a plasma chamber is the ideal method to increase the material's polarity. The free radicals and other particles that exist in the highly active plasma discharge can attach to the material surface resulting in the formation of additional polar groups on the material surface, these have a strong chemical attraction to inks, paint, coatings, adhesives etc. leading to significantly enhanced surface energy and therefore adhesion. Atmospheric pressure plasma system readily solve surface adhesion problems for a wide variety of products and applications : Easy to use : Mobile for testing in various departments, and for various parts and projects. Connect to mains power and the unit is ready. Fast treatment times : High power impact enables treatment times from 10-180 seconds, depending on material. Vacuum level : The unit operates at a vacuum level 1-4 mbar. Visible plasma process : Metal door with inspection windows. Treament results fully transferable : Using the same concept ensures easy upscaling to full scale production units. Rubber and plastics industry : Rubber, plastic material surface treated to form one active layer, the better for printing, adhesive, coating and other operations. Automotive industry : Ignition coil processing, instrument panel (PU) flexible polyurethane coating pre-treatment in the control panel before the bonding process, the internal parts. before planting adorned processing PP,Door seals The electronics industry : Hard plastic pieces, earphone, cell phone case. Medical industry : Intravenous infusion, catheter. Textile fibers industries : Woven flame retardant treatment, singeing treatment, splashing Water treatment, non-slip handle, antistatic treatment, coating, anti-bacterial deodorant processing, printing and processing, with a variety of non-woven textile composite acupuncture treatment, as well as non-woven fabrics with a variety of materials (plastic, film, textiles, etc.) bonding, etc. The effect of the plasma changes by varying the process parameters such as pressure, power, process time, gas flow and composition. Several effects can therefore be achieved in a single process step.

...more

STATIC WEB CLEANER MACHINE

Eltech developed static web cleaning system for high quality of printing. Static web cleaner removes static charge from material and removes the dirt from web. Problem : Dirty webs causing loss of profit and customer dissatisfaction. Excessive down time on printing presses. High reject rates in laminating processes. Unacceptable quality in pharmaceutical or food packaging.

...more

Static eliminator power unit

The instrument produces high voltage, low current in a controlled and safe manner. It's compact size and structure is suitable for most industrial environments. The defect free products and quality ensures efficient use and maximum customer satisfaction. We have designed the Eltech 331 Static eliminator power supply and the different discharge bars for active discharging of disruptive static charges, which develop during the production processes. The discharge bars and the power supply are used primarily in cases where disruptive static charges on fast moving material webs impair production processes and required to be eliminated. Features & Benefits : Consistent, uniform winding gives more robust and stable performance More powerful static neutralization, lower electrical stress and increased reliability Short circuit current of less than 5 mA ensures high level of operator safety IEC fused mains connector Enables fast and easy connection to mains supply and reduced installation time Maximum load Equivalent to 10 metres of ionizing appliances and cable Application : Packaging Plastics Paper Food Pharmaceutical Medical Automotive Electronics Textiles Optics.

...more

STATIC CHARGER

Eltech Engineers is well known firm famous for manufacturing innovative industrial products i.e. static charger is one of them. This static charger is useful during injection molding process to stick poly propylene / polyester films / thin biaxial oriented poly propylene films / water resistance films / fire protection film / photo sun film / flex board film / crystalline films / polystyrene foil material to the inner mold surface. Special care has been taken while designing and manufacturing of such high class products to match with the international quality and considering industrial safety standards & of course as per customers’ needs to satisfy them which are on the top priority. That’s why Eltech Engineers is leading name in the same field of producing & supplying superior quality static charger at reasonable price to cope up with completive market environment. These machines are suitable for thin foil charging in injection molding and blow molding machine i.e. portable applications in domestic as well as industrial use. In-mold decorating is very tedious process used for decorating and labeling on plastic & similar items. This is unique method in which label or hallmark or any decorative sign is truly embedded on the wall of object to make its uniform design match with the actual product appearance. This label or sign replaces the plastic resin extruded from job and makes the product more attractive. This integral sign or hallmark is not pasted with any type of glue, but it is placed in the open mold and the object is placed closer to sign. This sign then takes the place of the cavity or space extracted from object by means of In-mold processing. These applications provides the charming and attractive look to end product with multi color foil on multiple of plastic products such as tumbler, Tiffin boxes, water mugs, jugs & containers, glass, decorative coasters, serving trays, ice trays, buckets, plast water bags, wall clocks, thermal casseroles, compass box, household thermal products, various gift items, decorative items, sign boards, vehicle no. plates, logos on which injection molding process can be carry out. Salient Features Due to user friendly design & excellent clarity these static chargers have wide flexibility in operation Superior Quality makes these equipments ease to use, no special skill is require to operate For extreme safety, high quality of insulation material is used while manufacturing. Free from any type of leakage currents as well as shocks i.e. shock proof design. Strict quality check at each stage of production makes these machines suitable for wide range of multiple of applications. These static chargers are sealed hermetically to enhance the utilization in extreme weather condition. Absolutely zero maintenance makes these machines for trouble free operation over a lifelong period. Suitable for films having lower density nearer to 0.90 g/m which makes them versatile in operation Provides excellent glossy look, extreme transparency & fine finish to any job profile.

...more

STATIC CHARGE METER MACHINE

The Static Charger Meter is non-contact, hand held, light weight static monitoring and locating instrument. It utilises a precision LCD display to indicate the magnitude and polarity of the electrostatic charge. The static charge meter incorporates state-of-the-art circuitry, to enable measurements to be made for as long as 30 seconds without significant drift. In practice, measurement time is usually less than 10 seconds. The Static Charge Meter has good directional sensitivity and is ideal for measuring electric charges encountered in critical electronic assembly and storage areas as well as Antistatic Work Stations. It can also be used for Plastics, Paper, Textiles, Food, Explosives and Pharmaceutical Industries. The Static Charge Meter gives direct readings of electrostatic potentials on any surface, when held at a distance of 50 mm. However, virtually any electrostatic potential can be measured by proportionately increasing the distance from the meter to the charged object. The use of very low current circuitry results in a long battery life of over 6 months under normal use. The Static Charge Meter gives direct readings of electrostatic potentials on any surface, when held at a distance of 50 mm. However, virtually any electrostatic potential can be measured by proportionately increasing the distance from the meter to the charged object.The Static Charge Meter gives direct readings of electrostatic potentials on any surface, when held at a distance of 50 mm. However, virtually any electrostatic potential can be measured by proportionately increasing the distance from the meter to the charged object.

...more

SHOCKLESS ELECTRODE

The emitter points of a shock-less static eliminator receive high voltage indirectly. If someone touches the ionizing points, he will feel only a minor tingling sensation. The ionized field is most intensely closed to the emitter pins. The best distance for good static neutralization is between 10 mm to 20 mm.

Weight : 6 Kg

...more

Sheet Corona Treater

Eltech sheet corona treater is widely used to treat PP,PVC and metallised polyester laminated sheets to increase surface tension and gives better printing and adhesion. Water-based and UV inks printed on plastic films and other substrates create a need for the substrate to be treated prior to printing. Conventional method of roll to roll treatment is standard practice, but in Offset, Sheet corona treatment is required to increase surface tension or improve the printability. Some substrates are corona-treated when they are manufactured. Many of these substrates require a surface energy boost to match a particular ink or coating. This is done with corona pretreaters on the press just prior to the coating application point. PVC, PP, LD, Foam, Flex, metallized polyester, PE, OPP and other high-low density plastic materials should particularly be Corona treated to enhance the quality of the final product.

Speed : 30 - 80 meter/minute

...more

Semi-Automatic Induction Cap Sealer Machine

Eltech S-500,Semi-Automatic Induction Cap Sealer is specifically designed for packagers who require a semi-automatic sealing process with low production volumes. The table top model is compact and ideal for production environments where a bottle conveyor is not practically necessary. Built-in guides ensure operators properly line-up containers for sealing. A digital timer lets the operator know when the sealing process is completed. This model is suitable for batch type production and can be used continuously for 24hrs x 365 days. Ideal for laboratory use, stability testing, R & D facilities, short runs test marketing. Advanced Mosfet / IGBT technology Delivers high efficiency sealing power and long term reliability. Sealing time in 1/10 second increments. Compact in size. Handle provides portability with skid-free non-marring feet for use anywhere. Automatic photoelectric switch under sealing head eliminates the need for finger switches to start sealing cycle. "V" stop centering guide for assurance of bottle being under sealing head. No tools are required for adjustment or set-up. It requires no water and is 100 % air cooled. It is silent and has no discharge. Digital UP/Down timer: Provides precise timing from 0.1 to 9.9 seconds. Can seal PET / HDPE / PP / LDPE / PVC / GLASS containers. User friendly Continuous use, rugged built ensures long serving life Fast and easy set up, no moving parts Light weight design ensure easy mobility Safe, reliable and compact.

Weight : 23 Kg Net /Packed : 40 kg

...more

ROUND BOTTLE TREATMENT MACHINE

We are offering a precision- engineered collection of Round Bottle Treatment in Corona Treater and these machines are popular amongst our clients for durability and high efficiency. Utilizing corona treatment, we set new standard for surface treatment technology and it is possible to corona treat PET, PP, PE cylindrical containers in printing, labeling, molding and filling production line.

...more

Plastic Film Blowing Machine

Warranty : 1 Year

Plasma Treatment Wire

In Wire & Cable industry with increase in technology, Wire & Cable industries runs machines at High Speed, So that they can increase the Production and achieve economic of scale. At such a high speed there is always a problem of wettability and adhesion, ink gets peel off, with Plasma Treater we ensure there is wettability and proper adhesion, so that ink doesnot get peel off at High Speed. Also material such as HDPE & LDPE, even at Low speed there is Problem of wettability and Adhesion, we had designed Atmospheric Plasma Treater to solve the long run problem of wire & cable industries to ensure there is wettablity and adhesion, so that there is proper bonding between inks & polymer.

...more

Plasma Treatment For Plastics

Eltech plasma surface treatment of plastic to enhance adhesion before inkjet printing. Generally, plastics have chemically inert and nonporous surfaces with low surface tensions. This makes them non-receptive to bonding with inks, adhesives, coatings, and other substrates. Plasma Treater improves the adhesion of plastics. Polyethylene and polypropylene for example have very low surface energy. Pretreatment of these and other engineered plastics improves bonding prior to printing, coating, and laminating. The best type of surface treater for your application will depend on several variables such as Line Speed, Material & Treatment width.

...more

Plasma Treatment For Automobiles

Generally, plastics have chemically inert and nonporous surfaces with low surface tensions. This makes them non-receptive to bonding with inks, adhesives, coatings, and other substrates. Plasma Treater improves the adhesion of plastics. Polyethylene and polypropylene for example have very low surface energy. Pretreatment of these and other engineered plastics improves bonding prior to printing, coating, and laminating. The best type of surface treater for your application will depend on several variables such as Line Speed, Material & Treatment width.

...more

Plasma surface treatment before printing

Warranty : NA

PLASMA ION TREATMENT Machine

Eltech’s Plasma ION provides an economical solution for cleaning & activation of component surfaces before further processing. Plasma surface treatment improves wettability and adhesion of ink, glues and coatings on many different surfaces. Eltech’s Plasma treater etches , cleans , activates , sterilizes & functionalizes a wide variety of difficult to treat conductive and non-conductive material surfaces. Plasma offered by Eltech permits east surface treatment of a large variety of parts. Its concept based on three principle oh high voltage discharge in a high frequency area. Compressed air presses the discharge outside the nozzle head. The entire system is easily integrated into new or existing production lines. The system consist of a plasma generator with nozzle assembly. Benefits Of Plasma Treatment Over Acid Improves the physical properties of etched material. Unlike Acid, Plasma is also an excellent cleaner & removes all the unwanted organic residues from the metal surfaces. Although plasma improves chemical & physical properites of the metal but it does not change any property. By-products formed during plasma etching are volatile. Plasma etching is less risky than acid. Atmospheric pressure plasma system readily solve surface adhesion problems for a wide variety of products and applications : Improve folding carton bond strength Painting and decorating Extruded pipe, tubing, profiles Medical and Pharmaceutical Electrical/electronic components Direct printing Hot stamping Laminating Pad printing Adhesive coating Wire and cable DCM Automotive – ABS,bonding of headlight &tail lights Packaging, Transportation, Consumer goods, Textiles, Life sciences, Aerospace & many more.

...more

PLASMA ARC TREATMENT

Eltech's Plasma Arc treatment system is perfect solution to adhesion problems on injection, blow moulded or extruded parts of PE, PP, PET, nylon, vinyl, polystyrene, polycarbonate, PVC, fluorocarbons and all other types of thermoformed and thermoset plastics. plastic surface treatment is achived with Plasma Arc treatment. Plasma Arc can be used in a very flexible way, since a counter electrode is not needed. Atmospheric Plasma Treatment can be used in a very flexible way, since a counter electrode is not needed. The discharge is ignited between a pair of electrodes inside the treatment tool and gets directed towards the substrate with a minor laminar air flow.

...more

Ozone Generator

Ozone (O3) is sometimes called "activated oxygen", basically an allotropic form of oxygen consisting of molecules containing three oxygen atoms. It can be act as a most powerful sterilant to destroy bacteria, viruses and odors if generated in controlled conditions. Ozone generators are machines that convert Oxygen (O2) in to Ozone (O3) by the use of high voltage electricity with the help of ozone generators manufactured by Eltech Engineers at state of art unit. Ozone can be neither store nor transported because of unstable tendency to breakdown quickly as it’s a basically molecular detention process that must be carried out with ozone generators. Ozone is very powerful and it has very short life span. When it dispersed in a closed room or vicinity, oxidation process starts and then it perform its job and just disappears. Ozone must be generated at site only. Its life cycle comprises of Generation, Oxidation & Return to oxygen. Ozone can effectively neutralize or kills bacteria, fungus & germs by attracting itself to the contaminants breaking down the cell structure through oxidation and reverting back to oxygen. Ozone is used as a sterilant agent for bleaching, cleaning and oxidizing and has faint chlorine like odor. Ozone is not a stand-alone mold removal tool. Eltech Engineers is a certified Indian Manufacturer of different types of Ozone Generators & Ozone Systems from 500 mg/hr to 5 kg/hr as per requirements of customers. Salient Features Ozone can kills or completely neutralize bacteria, fungus & germs by means of oxidation process which is safe if carried out in a controlled conditions with the high class Ozone Generator manufactured and supplied by Eltech Engineers at very affordable prices. Even it can detect and kill such harmful bacteria which humans can’t smell it. Multi specialty hospitals across the world use large ozone generators to decontaminate the operating rooms between surgeries. This need closed air tight room sealed with proper sealing agent. Due care need to take that Ozone should not be used in occupied spaces. Ozone is safe to use in unoccupied spaces by trained individuals, who follow appropriate occupational, health and safety requirements offers excellent results. Ozone generators should only be used by trained professionals in unoccupied spaces at the recommended threshold levels. Ozone air purifier – This machine effectively kills and completely neutralizes the bacteria, virus, harmful microbiological substances present in an air and also called as Ozone deodorizer which is really innovative machine offer by Eltech Engineers. Ozone vegetable purifier – As per its name, this purifies and maintains the freshness of all types of vegetables by removing or completely neutralizing the bacteria within. Used in various malls and rich class hotels for preserving vegetables. Drinking water / Swimming pool or water park water treatment application – Ozonation is one of the best suitable methods of obtaining pure drinking water from impure water. Ozone will destroy all unwanted bacteria and virus i.e. both organic as well as inorganic substances will get oxidize. This improves the water taste, removes odor and provide excellent disinfections. This ozone generator also removes the harmful bacteria & algae from swimming pool water & maintains the water suitable for all human being of different age groups by means of oxygen enrichment process. Hotels, Restaurants, Motels, Room Odor Removal / Bacteria killing – These needs ozone generator to keep high standards of hygiene and customer’s health by performing deodorizing functions. Suitable ozone units are being installed in kitchen, halls, lounge, bars, rest rooms, bathrooms, spas, offices, store rooms, garbage rooms, bedrooms, lifts, terrace side suits etc. Wide applications in agriculture and green house farming, zoo, fish aquariums, life support systems and fish farming, museums, culture halls, multiplexes etc. Ozone air purifier used to purifies air and eliminate smell and oxidization of by-products in air conditioning equipment which also removes the indoor pollution. Eltech Engineers is famous for manufacturing Ozone air purifiers, also called as ozone deodorizers which are equipped with timer facility. Suitable for grain processing, food processing industry to kill insects, molds and other fungus Ozone generators are also used for laundry applications to remove stains, odor from clothes and Bleaching of fabrics. This washing cycle is associated with some suitable cleaning laundry chemical in conjunction with ozone for effective cleaning of clothes. Textile mill application involves removal of dyes from waste water i.e. Effluent water treatment as well as coloring process on fabrics as per requirements. Cooling towers water treatment – Ozonization is general requirement for such cooling water treatment to remove algae and odor form circulating water. Also removes sticky dust and purifies water for cooling numerous electrical as well as mechanical auxiliaries. Same method is applicable for industrial Effluent water treatment plants which save the water in huge quantity and thereby saving in terms of money. Vehicle wash water reclamation – This reclamation process includes the recovery of water consumed during cleaning of vehicles by removing sticky grease, dust, sediments. Such ozone generator are installed at vehicle service stations as per requirements. Marine waste water treatment in shipyards and jetties, Aircraft odor and fungi control Bottled water, cold drinks, and beverage plants School buses and classrooms for air freshness and odor removal for maintaining hygiene. Building cleaning services such as big apartments, offices etc.

...more

OZONE EXTRACTION BLOWER Machine

Eltech features a full line of Silicone Ozone Extraction blower efficiently removes ozone and cools electrode and silicone sleeves. An ozone Extractor Blower is a necessary a part of each Corona treatment system. The ozone Extractor Blower has two vital functions. initial of all it removes the ozone that's created within the Corona treatment process. second it's a cooling effect on the electrode and also the backing roller within the Corona treater.

...more

MULTILAYER FILM PLANT MACHINE

Corona treatment system is a very effective way to increase the surface tension of virtually any material. Surface treatment is required for plastic films/fabrics whose normal surface tension is not sufficiently high to permit good wetting by flexo graphic inks. Features : High frequency generators are with IGBT technology.

...more

LABORATORY CORONA TREATER

LABORATORY TYPE CORONA TREATMENT TO TREAT LABELS FOR TESTING PURPOSE IN LABORATORY Corona treating is a very effective way to increase the surface tension of virtually any material. When properly applied to your substrate, corona treating produces the higher surface dyne levels needed for good adhesion even on the more difficult-to-treat materials like polypropylene and polyethylene. Other common corona treating applications include nylon, vinyl, PVC, PET, metallized surfaces, foils, paper, paperboard stock, and other materials. For the treatment of sample film prior to adhesion or printing. The film to be tested is placed on the earthed base plate and is then passed over with the manual roller electrode. The generator power can be set and is displayed. The intensity can also be regulated by varying the movement speed. The unit is most suitable for quick and simple tests. The compact design of the unit allows it to be taken to a customer and to perform tests on site. The device comprises a semi-conductor generator with an integrated transformer for high-voltage generation, the hand roll electrode (standard working width 200mm), the earthed ground plate power cable and a hand or foot-operated switch for the activation of the Corona discharge. The output (intensity of the Corona discharge) can be adjusted at a potentiometer and read off a display. The purpose of corona treatment is to optimise the adhesion properties on polymer-based materials. The low surface energy of polymer-based substrates often leads to poor adhesion of inks, glues and coatings which by nature present significantly high surface energies. To obtain optimum adhesion, it is crucial that the surface energy of the substrate is equal or higher than the surface energy of the material to be applied to the polymer. Easy Installation Installation and start-up are remarkably easy with a plug and play design. Simply roll the system into place, connect to your exhaust, power up the system and converters are ready to treat.

Weight : 32 kg

...moreBe first to Rate

Rate This