Phosphorus Copper Anode

460 Per Kilogram

Welding Electrodes and Filler Wires

Get Price Quote

A reputed industrial organization, based in Mumbai, Maharashtra, India, we are considered one of the foremost manufacturers, exporters and wholesale suppliers of world-class Welding Electrodes and Filler Wires. We offer a wide array of Welding Electrodes and Filler Wires of various grades based on their applications. Some of our fast-selling Welding Electrodes and Filler Wires are 304L welding electrodes and filler wires, 316 and 304 grades of welding electrodes and filler wires.

Best Deals from Electrical Components

Zinc Anodes

280 - 300 Per Kilogram

We are the main supplier of this product.

Stainless steel tig filler rod

325 Per

100 Kilogram (MOQ)

Tungsten Electrode

Get Price Quote

product details: size 1 mm, 2.5 mm, 3.15 mm, 5 mm length 150 mm with the aid of our expertise, we prashaant steel are able to offer a superlative quality of tungsten electrode. It is widely used as high thermal and high electrical conductivity in various welding process. The offered product is manufactured using the standard quality raw material under the strict surveillance of vendors' professionals as per the set industry norms. Our offered product is rigorously examined under the keen eye of our skilled quality controllers to ensure excellent quality. Further, it can be availed at an affordable price with no constraint. features: tough and tensile rust proof high resistance to contamination specifications: electrode type current applications welding properties wl15 - gold plus(1, 5 % lanthanum oxide, gold) ac/dc non-alloyed and low alloy steels stainless steels aluminum alloys magnesium alloys titanium alloys nickel alloys copper alloys very good ignition and re ignition properties high service life very good arc stability suitable as a substitute for wt20 wl20(2,0 % lanthanum oxide, blue) ac/dc non-alloyed and low alloy steels stainless steels aluminum alloys magnesium alloys titanium alloys nickel alloys copper alloys very good ignition and reignition properties, in particular at high currents high service life very good arc stability suitable as a substitute for wt20

Nickel Welding Rod

2,000 Per Kilogram

Stainless Steel Welding Electrodes

Get Price Quote

We offer Stainless Steel Welding Electrodes in different specifications. Stainless Steel Welding Electrodes have good corrosion resistance and oxidation resistance, which make them durable and highly efficient. These Stainless Steel Welding Electrodes are widely used in chemical, fertilizer, oil, and medical machinery manufacturing. Besides, we provide Stainless Steel Welding Electrodes at very competitive price. Highlights : Corrosion resistance Impervious to air and water Non-magnetic Durable

Stainless Steel Welding Electrodes

Get Price Quote

We are offering stainless steel welding electrodes e308h. stainless steel welding electrodes welding rods the welding rods that we suppiy from "smp" korea & many make of welding consumables are available as per the requirernents of our highly esteemsd clients smp welding consumables brand name: smp-e308-16,smp-e308l-16,smp-e308h-16, smp-e309-16,smp-e309l-16,smp-e309cb-16 smp-e309mo(l)-16,smp-e310-16, smp-e312-16 smp-e316-16,smp-e316l-16,smp-e317-16 smp-e347-16,smp-e2209,smp-e410 these are extensively used for different purposes in many industiries.all position electrode, vertical up or down overhead,horizontal,ideal thick to thin work, for dirty & greasy steels, less splatter, self-releasing slag, boiler applications, industrial usage, furniture, dairy plants, chemical plant, water piper, boilers & others.

Copper Cathodes

Get Price Quote

We are a leading Manufacturer and Exporter of excellent quality Copper Cathodes, which are used in varied industries. Our range of Copper Cathode is known in the industry for its superior performance and exceptional quality. Latest machines and technology is used and advanced production process is followed in the fabrication of the Copper Cathode. Also, we have established a name of repute among the Copper Cathodes manufacturers and exporters in India. Clients are eased with the availability of Copper Cathodes at market leading prices. FeaturesFriction resistantPrecise dimensionExcellent performance Long-lasting In Demand ByWire industryCable industry Used To ProduceCast copper rodHigh quality copper tubeIngotsExtruded copper products

Welding Electrodes

Get Price Quote

We offer the best quality Welding Electrodes that are made with high quality raw materials. Welding Electrodes, that we offer, are widely used in various applications. These corrosion resistant Welding Electrodes are in extensive demand everywhere, owing to their precision engineering and perfect finishing.

Cross Clamps

Get Price Quote

Cross Clamp for Earth Tape / Earth Round Bar / Earth Round Bar & Tape Type - HOT DIP GALVANISED STEEL HDG Steel Cross Clamp equipped with 4 Galvanised Screws & Nuts M8 x 25, suitable to connect-A) 8 mm or 10 mm Round BarsB) Galvanised Plates with maximum width of 30 mm.

Welding Electrodes

3,000 Per Piece

Sheet,Plate & Coil

Get Price Quote

we stock and supply all sizes of all grade materials of 200, 300, 400 series Grades. We are Specialized in Magnetic Sheets in Grade of 409N, 410S, 410, 420, 430, 431 User Industries: Chemicals, Fats, & Fertilizers, Sugar Mills & Distilleries, Cement Industries, Ship Builders, Paper Industries, Pumps, Petrochemicals, Oil & Natural Gas Organization in terms of the specific materials, Technology, Finance & Personal. Product Range: The following table represents size range, product standards and material grades of Sheet, Plates & Coils

Air Conditioner Bright Soft Copper Coil

500 Per Kilogram

Thoriated Tungsten Electrode

Get Price Quote

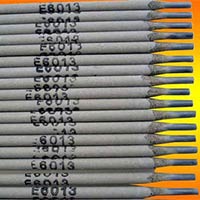

6013 Mild Steel Welding Electrode

Get Price Quote

100 Box (MOQ)

Virat Superior Welding Electrodes Grade 6013 is a rutile based medium coated, all position electrode used for general purpose welding. The electrode is well suited for AC as well as DC (). The weld metal possesses excellent mechanical properties and is of radiographic quality. Application Virat Superior Welding Electrodes Grade 6013 is steel, sheet metals, steel structures & bridges, etc. Smooth and stable arc. Normal spatter with easily removable slag. Weld metal bead with uniform ripples and suitable for welding of mild shining appearance. Balance coating formulation for suitability on DC as well as AC with low open circuit voltage. Very suitable for general purpose welding in all positions

D & H Stainless Steel Welding Electrode

750 Per

100 Kilogram (MOQ)

Precaution Ensure the electrodes are dry. Re-dry the electrodes at 200-250°C for one hour. Use short arc and minimum heat input.

screw down test clamp

Get Price Quote

Stainless Steel Filler Wire

250 - 450 Per Piece

50 Kilogram (MOQ)

lead anodes

Get Price Quote

2 Ton (MOQ)

HMS Metal Corporation is a Leader in the production and Supply of Anodes used in copper, zinc and nickel refining. Our electrowinning anodes integrate years of experience, research and development.With fully Integrated & 100% in-house production facility we are able to Internally controlled workmanship for alloying, rolling blade, head bar tinning and casting, welding, cutting & packaging. Although anodes are manufactured to client’s designs, with each stage of manufacture using the best quality raw materials and controlled by a strict quality process system, anodes are produced efficiently and consistently within estimated time. Anodes made of lead alloys are used in the electrowinning and plating of metals such as manganese, copper, nickel, and zinc. Rolled lead-calcium-tin and lead antimony alloys are the preferred anode materials in these applications, because of their high resistance to corrosion in the sulfuric acid used in electrolytic solutions. Lead anodes also have high resistance to corrosion by seawater, making them economical to use in systems for the cathodic protection of ships and offshore rigs. Rolled lead anodes have become the industry benchmark with the benefits of fine grain structure, less segregation and elimination of cracks and voids resulting in more uniform corrosion of the anode. The shape and size of the copper bar and the anode plate are made to customer specifications The copper bar is tin-plated and then given a homogeneous coat of lead several millimeters thick as protection from corrosion caused by aggressive acid mist. This method of protecting the anode bar also ensures the best possible bond between lead and copper for improved current flow and long service life. Chemical Composition The lead anodes are manufactured in calcium-tin-lead (Ca/Sn/Pb), antimonial lead (Sb/Pb) and silver-lead (Ag/Pb) alloys which are the preferred alloys for these applications with their high resistance to corrosion in the sulphuric acid based electrolyte solutions. Lead anode alloys generally consist of tin, Calcium, and Antimony. The favoured alloys, based on the specific application, are lead- antimony as well as lead-Calcium-Tin alloys. One reason for this is because of the alloys’ resistance to corrosion in the sulfuric acid that’s used for electrolytic solutions. (Lead-alloy anodes are used in electro winning – also known as electro extraction – as well as for plating metals such as manganese, copper, nickel, and zinc.) Lead anodes have superior attributes, such as being highly resistant to the corrosive effects of seawater. We also offer custom Lead Alloys to meet your specifications We specialize in manufacturing complete Lead Anode and Anode Plates for Zinc, Nickel and Copper extraction electrolysis plant. Electrowinning of copper, nickel, cobalt and zinc in SX-EW processing of ores. Ca/Sn/Pb alloy is generally used for copper, nickel and cobalt applications. Ag/Pb alloy is the preferred alloy in zinc electrowinning Packing The finished anodes are packed together in wooden pallets with thick thermocol in between each Anode to prevent the individual anodes from bending.Do's & Dont;'s Remember, proper care of anodes will pay off in longer life. Try these suggestions with new Republic anodes. Do not leave new anode in chromium solution when tank is idle. Instead, remove them and place them in clean water after use until a uniform brown film of lead peroxide is formed on the surface. Do not confuse this dark brown lead peroxide coating with lead chromate. Lead chromate (PbCrO4) is yellow in color and acts as an insulation. This should be removed in order to restore the anode to the most efficient service level. We recommend that approximately two inches of lead anode be above the solution level at all times. We do not recommend mixing old and new anodes together. Adding new anodes intermittently in order to obtain amperage needed could result in new anodes scaling up very rapidly. If it is not practical to replace all anodes at one time, we suggest extreme care be given to the new anodes to assure proper breaking in for efficient performance.