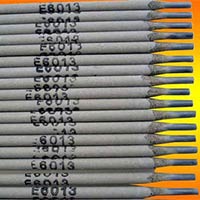

6013 Mild Steel Welding Electrode

Get Price Quote

100 Box (MOQ)

Virat Superior Welding Electrodes Grade 6013 is a rutile based medium coated, all position electrode used for general purpose welding. The electrode is well suited for AC as well as DC (). The weld metal possesses excellent mechanical properties and is of radiographic quality. Application Virat Superior Welding Electrodes Grade 6013 is steel, sheet metals, steel structures & bridges, etc. Smooth and stable arc. Normal spatter with easily removable slag. Weld metal bead with uniform ripples and suitable for welding of mild shining appearance. Balance coating formulation for suitability on DC as well as AC with low open circuit voltage. Very suitable for general purpose welding in all positions

Solenoid Coils

100 - 10,000 Per Nos

10 Piece (MOQ)

Solenoid coil of all types

Best Deals from Electrical Components

Welding Rod

Get Price Quote

100 Piece (MOQ)

Electrical Rescue Kit

5,000 Per

1 Piece (MOQ)

Zinc Anodes

Get Price Quote

We have integrated our experience and available facilities effectively to manufacture a premium collection of Zinc Anodes. These are made from quality assured materials in compliance with the defined quality standards.

Electrical Components

Get Price Quote

We are well known for supplying of wide variety of Electrical Components.

Phosphorus Copper Anode

460 Per Kilogram

lead anodes

Get Price Quote

2 Ton (MOQ)

HMS Metal Corporation is a Leader in the production and Supply of Anodes used in copper, zinc and nickel refining. Our electrowinning anodes integrate years of experience, research and development.With fully Integrated & 100% in-house production facility we are able to Internally controlled workmanship for alloying, rolling blade, head bar tinning and casting, welding, cutting & packaging. Although anodes are manufactured to client’s designs, with each stage of manufacture using the best quality raw materials and controlled by a strict quality process system, anodes are produced efficiently and consistently within estimated time. Anodes made of lead alloys are used in the electrowinning and plating of metals such as manganese, copper, nickel, and zinc. Rolled lead-calcium-tin and lead antimony alloys are the preferred anode materials in these applications, because of their high resistance to corrosion in the sulfuric acid used in electrolytic solutions. Lead anodes also have high resistance to corrosion by seawater, making them economical to use in systems for the cathodic protection of ships and offshore rigs. Rolled lead anodes have become the industry benchmark with the benefits of fine grain structure, less segregation and elimination of cracks and voids resulting in more uniform corrosion of the anode. The shape and size of the copper bar and the anode plate are made to customer specifications The copper bar is tin-plated and then given a homogeneous coat of lead several millimeters thick as protection from corrosion caused by aggressive acid mist. This method of protecting the anode bar also ensures the best possible bond between lead and copper for improved current flow and long service life. Chemical Composition The lead anodes are manufactured in calcium-tin-lead (Ca/Sn/Pb), antimonial lead (Sb/Pb) and silver-lead (Ag/Pb) alloys which are the preferred alloys for these applications with their high resistance to corrosion in the sulphuric acid based electrolyte solutions. Lead anode alloys generally consist of tin, Calcium, and Antimony. The favoured alloys, based on the specific application, are lead- antimony as well as lead-Calcium-Tin alloys. One reason for this is because of the alloys’ resistance to corrosion in the sulfuric acid that’s used for electrolytic solutions. (Lead-alloy anodes are used in electro winning – also known as electro extraction – as well as for plating metals such as manganese, copper, nickel, and zinc.) Lead anodes have superior attributes, such as being highly resistant to the corrosive effects of seawater. We also offer custom Lead Alloys to meet your specifications We specialize in manufacturing complete Lead Anode and Anode Plates for Zinc, Nickel and Copper extraction electrolysis plant. Electrowinning of copper, nickel, cobalt and zinc in SX-EW processing of ores. Ca/Sn/Pb alloy is generally used for copper, nickel and cobalt applications. Ag/Pb alloy is the preferred alloy in zinc electrowinning Packing The finished anodes are packed together in wooden pallets with thick thermocol in between each Anode to prevent the individual anodes from bending.Do's & Dont;'s Remember, proper care of anodes will pay off in longer life. Try these suggestions with new Republic anodes. Do not leave new anode in chromium solution when tank is idle. Instead, remove them and place them in clean water after use until a uniform brown film of lead peroxide is formed on the surface. Do not confuse this dark brown lead peroxide coating with lead chromate. Lead chromate (PbCrO4) is yellow in color and acts as an insulation. This should be removed in order to restore the anode to the most efficient service level. We recommend that approximately two inches of lead anode be above the solution level at all times. We do not recommend mixing old and new anodes together. Adding new anodes intermittently in order to obtain amperage needed could result in new anodes scaling up very rapidly. If it is not practical to replace all anodes at one time, we suggest extreme care be given to the new anodes to assure proper breaking in for efficient performance.

Welding Electrodes

Get Price Quote

We deal in Welding Electrodes featuring a diameter of 3.2m-4 mm and a length of 400mm. Our company has a convenient and noncomplex payment procedure. Patrons can make payments through a method with they are comfortable. We are open to receiving payment online or offline. Rest assured us for the quality of all products we deliver as the inputs used commensurate to international set standards and thus, the products are remarkable and meet your satisfaction level.

40x2meter gi earthing electrode

1,050 Per unit

5 16 (MOQ)

ignition electrode

1,000 Per Piece

flameproof equipment

Get Price Quote

SS Welding electrode

Get Price Quote

With a focus on the ever-evolving demands of our customers, we have come up with a wide range of uniquely designed SS Welding Electrode. Specifications: Welding Current: 90-120 Diameter: 2.0/2.5/3.2/4.0/5.0 mm Length: 300 mm-350 mm Operating Current: 100-200

Nickel Welding Rod

2,000 Per Kilogram

Copper Earthing Electrode

5,000 Per Piece

Copper bonded earthing electrode with back fill compound quality export copper rod earthing electrode gel earthing.

aluminum hull anodes

230 Per Kilogram

We are the main supplier of this product.

Tungsten Electrode

Get Price Quote

product details: size 1 mm, 2.5 mm, 3.15 mm, 5 mm length 150 mm with the aid of our expertise, we prashaant steel are able to offer a superlative quality of tungsten electrode. It is widely used as high thermal and high electrical conductivity in various welding process. The offered product is manufactured using the standard quality raw material under the strict surveillance of vendors' professionals as per the set industry norms. Our offered product is rigorously examined under the keen eye of our skilled quality controllers to ensure excellent quality. Further, it can be availed at an affordable price with no constraint. features: tough and tensile rust proof high resistance to contamination specifications: electrode type current applications welding properties wl15 - gold plus(1, 5 % lanthanum oxide, gold) ac/dc non-alloyed and low alloy steels stainless steels aluminum alloys magnesium alloys titanium alloys nickel alloys copper alloys very good ignition and re ignition properties high service life very good arc stability suitable as a substitute for wt20 wl20(2,0 % lanthanum oxide, blue) ac/dc non-alloyed and low alloy steels stainless steels aluminum alloys magnesium alloys titanium alloys nickel alloys copper alloys very good ignition and reignition properties, in particular at high currents high service life very good arc stability suitable as a substitute for wt20

Stainless steel tig filler rod

325 Per

100 Kilogram (MOQ)

pole line hardware

Get Price Quote

pole line hardware, Cables, Connectors, Earthing Materials, Wires

Stainless Steel Welding Electrodes

Get Price Quote

We offer Stainless Steel Welding Electrodes in different specifications. Stainless Steel Welding Electrodes have good corrosion resistance and oxidation resistance, which make them durable and highly efficient. These Stainless Steel Welding Electrodes are widely used in chemical, fertilizer, oil, and medical machinery manufacturing. Besides, we provide Stainless Steel Welding Electrodes at very competitive price. Highlights : Corrosion resistance Impervious to air and water Non-magnetic Durable