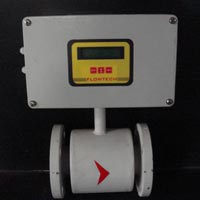

Electromagnetic Flow Meter

Get Price Quote

Process Control Devices offers a series of digital flow meters. Design to measures the flow rate of a liquid flowing through the close pipe. The electromagnetic flow meter is volumetric flow meter having no obstruction as there are no moving parts. Hence pressure drop is negligible. The performance is independent of density, viscosity, temperature, and pressure of the flowing liquid. The magnetic flow meter is calibrate using water and can measure the flow of other conductive fluids, with no further correction. This is a special feature that other type of flow meters doesn’t have. PCD is one of the leading Electromagnetic flow meter manufacturers in Mumbai India. Working Principle of Electromagnetic Flow Meter Electromagnetic flow meters work on the principle of “Faraday’s Law of electromagnetic induction”. According to the law, “when a conductive liquid cut the magnetic field, voltage Induce”. Further, that voltage signal is sensed by the electrode which is mounted on the wall of the flow tube. That induce voltage signal is process by the electronic transmitter to determine the flow. The generation of voltage is directly proportional to the velocity of the fluid. Construction of Electromagnetic Flow Meter Electronic Part consists of head type Flow Indicator which contains Microprocessor Controller chip mounted on the electronic circuit. It has the LCD display, Which shows the Current flow rate & Total commutative flow. Also, has a transmission feature of 4-20 mA output & RS 485 Communication with High & Low Flow Alarm. To operate it requires an external power supply of 24 VDC or 230 VAC. The mechanical part consists of Flow Tube, Lining such as of PTFE Or Neoprene, Electrode, Magnetic Coil, Flange connection. Flow Tube Material is non-wetted part and should be of the nonmagnetic material such as SS 304 Or SS 316. Selection of Lining Material must be according to temperature, corrosive property & compatibility of the measured fluid. Neoprene can resist general weak acid, alkaline corrosion and can withstand temperature unto 80Ë�C, but it has wear resistance. As PTFE (Teflon) has low wear resistance and have good compatibility to almost all strong acid, chemical, alkaline corrosion, ETP Water, Waste Slurry. And can withstand temperature up to 180Ë�C. Selection of Electrode Material must be according to corrosiveness of measured fluid. Mechanical Specification Line Size: 15 NB to 300 NB Lining Material: PTFE, EPDM, NEOPRENE Electrode Material: SS316, Hastelloy C, Titanium, Monel Design Temperature: Up to 150 DegC Connection: Flanged to ASA, BS, DIN Electronics Specifications Programming: By Membrane Key Power Supply: 24 VDC Isolated, 230 VAC, 110VAC Out Puts: 4-20mA, 4wire, Pulse, Communication : RS 485 MODBUS Accuracy: ± 1% of FSD & ± 0.5% on request Linearity: +/- 0.5 % Repeatability: 0.5% Silent Features Total / accumulated total / flow rate Auto empty-full pipe check Ultrafast response time 4-20mA and pulse output high and low alarm (2-relay output) Modbus (RS485) Can handle slurries and heavy particulates Good accuracy (0.5 to 1%) Can respond well to fast changing flows Insensitivity to viscosity, specific gravity, temperature and pressure (within certain limitations) Will work with laminar, turbulent, and transitional flows Virtually no pressure drop No moving parts Lining protectors available for harsh, chemically corrosive, and abrasive fluids Can respond well to fast changing flows