Zeiss METROTOM Metrotomography

Metrotomography, the fusion of metrology and tomography, offers new possibilities in industrial metrology. It is now possible to perform highly precise and non-destructive measurements in the areas where only external or destructive inspections or no quality assurance took place in the past. Inspectable materials: Plastics Light metal alloys (Al, Mg) Model construction materials (plaster, wood, bakelite, resin and sand cores) Ceramics and compound materials (depending on the density, porosity and composition) Steel Measuring range:Ø300 x 350 mm Key words or phrases: Computer tomography, non destructive measurement, non destructive testing, internal defects measurements, non contact measurement, x-ray measurement, reverse engineering, point cloud comparison, measurement against CAD model, section analysis, CAD comparison, internal and external parameters measuring machine, X-ray inspection, CT scanners, CT.

...more

Vacuum investment casting

Vacuum Induction Melting & Casting with ceramic crucibles and cooling devices for directionally solidified / single crystal solidification. Applications : For turbine blades and vanes for the Aircraft and Industrial Gas turbine industries.

...more

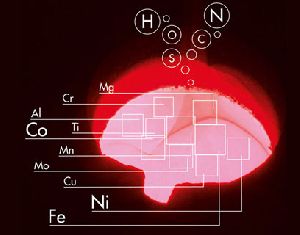

Vacuum Induction Plants for Melting and Gas Atomization

Applications : Production of Metal powder (Brazing powder, hydrogen storage alloys, Ni base alloy powder, plasma spray powder)

...more

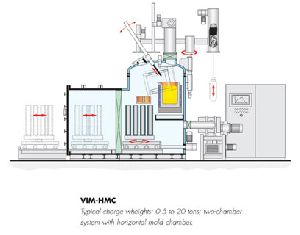

Vacuum Induction Melting Plants

Applications : Melting, Alloying and casting under vacuum of oxidation prone metals and alloys. Main uses are in R&D, Electronic Industry, Dental Applications, Aerospace and Precious Metal Industry.

...more

Vacuum Induction Degassing Plants

Applications : Alloying and degassing of small batches of special steels, casting under atmosphere or inert gas atmosphere. For special steel producers in steel plant and Foundries.

...more

Vacuum Arc Remelting Plants

Applications : Remelting of reactive metals like Ti or Zr, engineering steel as well as steels and superalloys for aircraft and energy application.

...more

sheet metal processing equipments

Induction Cold Crucible Melting

pplications : For melting and casting of reactive materials like Ti, Zr

...more

HOT ISOSTATIC PRESSES

A Hot Isostatice Press (HIP) is a pressure vessel with a unique combination of twemperature and pressure, Which makes it possible to heal internal voids in metal and ceramic materials and parts to susbstatially improve strength, starting from castings or encapsuated powder. Pressure 100-300 MPa. Presure medium is argon gas.

...more

FLEXFORM PRESSES

Quintus presses are designed with wire wound press cylinders and frames for excellent fatigue properties, long life, compact design and low –weight even at large press forces. Flexform is a sheet metal froming method for flexible ane cost-effective low-volume productions: Low tooling cost Short lead time High quality parts AEROSPACE : Structural items, Panel and engine componentsAUTOMOTIVE : Prototype and development parts. Low volume and niche-Vehicle parts.

...more

Electroslag Remelting Plants

Applications : Remelting of tool steels, cold rolls, engineering steel as well as steels and superalloys for aircraft and energy application.

Diameter : 200mm- 2300mm

...more

COLD ISOSTATIC PRESSES

A cold Isostatic press (CIP) is a pressure vessel used for pressing encapsulated metal and ceramic powder to achieve high density, high green strength and consistent properties before subsequent sintering. Pressure medium is water-oil emulsion.

...more

Cold Isostatic Press

A cold Isostatic press (CIP) is a pressure vessel used for pressing encapsulated metal and ceramic powder to achieve high density, high green strength and consistent properties before subsequent sintering. Pressure medium is water-oil emulsion.

...more

metal forming equipments

Be first to Rate

Rate ThisOpening Hours