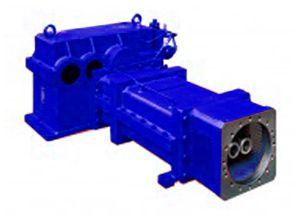

Extruder Gearbox

Get Price Quote

Premium Extruder Gearboxes

Get Price Quote

1 Piece(s) (MOQ)

union engineering co., a prominent name in the industry since 1974., offers single screw extruder gear units which are quite capable to transmit the high torque required for pressurising and plasticising moulding materials and also to absorb the high axial thrust load through built-in spherical roller thrust bearing. the axial bearing housing is standardised to accommodate suitable thrust bearings and corresponding output shafts with key are splined. the parallel shaft double reduction models – horizontal and vertical serve the characteristic requirements of the extruder gearbox.to incorporate the thrust screw , different thrust bearings with different bores are mounted on the output shafts (hollow) .the modular design permits the interchangeability of the parts. we are engaged in providing a wide range of extruder gearboxes, which is used in plastic and pvc extrusion. these ghe series greaves make gearboxes are high performing and easy to install. the high torque necessary for plasticizing and pressurizing molding material can be transmitted with the help of these gear units. through built-in spherical roller thrust bearing, the gear unit transmits high torque to absorb the high axial thrust load. moreover, to accommodate suitable thrust bearings, the axial bearing housing is standardized and the corresponding output shafts which come with key are splined. owing to our experience and coupled with modern technology and experience, we offer the finest extruder gearboxes of exceptional quality & premium choice for dependable services to our clientele. extruder gear product specification : ● premium greaves make “ghe” series gearboxes give high performance. ● the built-in spherical roller thrust bearing absorb the high axial thrust load , allowing these gear units to transmit the high torque necessary for plasticizing and pressurizing molding material. ● easy to install. ● to accomodate the suitable thrust bearings,the axial bearing housing is standardized and the corresponding output shafts that come with the key are splined. ● extruder gearboxes are used in plastic and pvc extrusion. ● shaft extension keyway : is:2048. ● maximum operating reliability. ● low noise and smooth running.

Best Deals from Extruder Gearboxes

Extruder Gearbox

15,000 Per Piece

Features: Optimum strength Robustness Effective usage

extruder gear boxes

Get Price Quote

Twin Screw Extruder Gearboxes

Get Price Quote

• Highest gearbox structure strength ensures minimum rotation vibration. • High torque and high output speed rate design. • Thrust bearing coupled in tandem way. • Precision gear grinding to keep operation noise below 80db. • Forced lubrication and built in cooling & filter system to ensure excellent heat dissipation. • Top quality barings form reputed manufacturers like SKF and or ZKL bearings. Corresponding to the increasing demand of the twin-screw extruder, P.G DRIVE had developed the series of high performance gearboxes for the twin-screw extruder. Extruders are commonly used equipment used in the industrial production of plastics. Twin Screw extruder’s machines require highly sophisticated gearbox to drive the co-rotating or counter rotating extruder screws. The design requires delivering the highest possible torque evenly in both the screws by utilizing the smallest amount of space. P.G.Drive with its reach experience in the gearing field has now indigenously developed its “TE” series of counter rotating and co rotating gear boxes. The gear unit consists of four sections, the reduction gear unit, thrust housing, distributor gear unit and adapter housing forming the connection with the extruder machine.

Extruder Helical Gearbox

30,000 Per Piece

extruder gear boxes

Get Price Quote

Extruder Gearbox

Get Price Quote

The gear units are quite capable to transmit the high torque required for pressurising and plasticising moulding materials and also to absorb the high axial thrust load through built-in spherical roller thrust bearing. The axial bearing housing is standardised to accommodate suitable thrust bearings and corresponding output shafts with key or splined.

Helical Single Screw Extruder Gearbox

Get Price Quote

Helical Single Screw Extruder Gearbox Power Range 5 KW to 530 KW Ratio Range 6.3/1 upto 80/1 Stage Single Double & Triple Screw Size Range 40mm to 150mm Product Details Esenpro make High Power Energy Efficient Single Screw Helical Extruder Gear unit are designed to withstand continuous running. The gearbox is specially designed to withstand high torque and absorbing the high thrust load generated by the Extrusion machines. Product Details Salient Features Extruder gearbox is capable to take high axial thrust upto load. The Gear Unit is incorporated with Spherical Roller Thrust bearing. External lubrication system can be provided along with Heat Exchanger. Gear rating is based on AGMA D104 & bearing life calculation is based on DIN ISO 281. Shaft configuration can be offered with single, double and multiple keyways or with splined shaft for extruder screw engagement. Barrel mounting can be matched to suit customer requirement by providing additional flanges on extruder mounting faces.

Extruder Gearbox

Get Price Quote